No reasonable council request refused . . .

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

WHEN was the last time a vehicle manufacturer asked for your advice? If you are a municipal authority, the answer could be quite recently, for when Norba UK wanted to build a new refuse collection vehicle the company asked more than 50 large councils what they wanted from a vehicle, then set about to make it.

The result — the Norba KSeries — makes its commercial debut at the Institute of Solid Wastes Management Show at Scarborough (June 22-25).

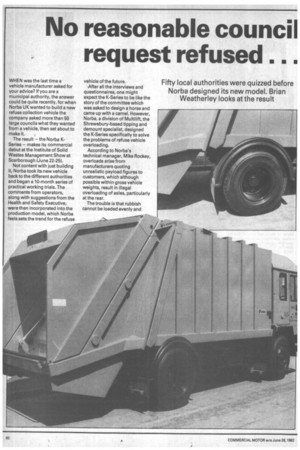

Not content with just building it, Norba took its new vehicle back to the different authorities and began a 10-month series of practical working trials. The comments from operators, along with suggestions from the Health and Safety Executive, were then incorporated into the production model, which Norba feels sets the trend for the refuse vehicle of the future.

After all the interviews and questionnaires, one might expect the K-Series to be like the story of the committee which was asked to design a horse and came up with a camel. However, Norba, a division of Multilift, the Shrewsbury-based tipping and demount specialist, designed the K-Series specifically to solve the problems of refuse vehicle overloading.

According to Norba's technical manager, Mike Rockey, overloads arise from manufacturers quoting unrealistic payload figures to customers, which although possible within gross vehicle weights, result in illegal overloading of axles, particularly at the rear.

The trouble is that rubbish cannot be loaded evenly and unless the vehicle is underloaded, the possibility of individual axle overloading is high. To achieve a legal payload, Norba has paid particular attention to the vehicle wheelbase and body geometry, distributing as much weight as possible in front of the rear axle, with the result that all models in the range offer good payloads within the legal limit.

Norba is confident that its 16-ton model, the MUN-16, can achieve a legal payload of up to seven and a half tons while remaining within existing axle plating, compared to the usual six tons.

Body improvements have also been made, in particular by using lightweight high-wearresistant steel in the hopper sides and packer plate edge which has reduced unladen weight without losing strength. The old Rhino type design has been reworked to give a smoother exterior body line with all cables and hydraulic lines being run through conduits.

Hitchen-based Norba UK occupies an unusual position in the UK market, where it is currently fourth behind Hestair Dennis, Shelvoke and Drewry, and Jack Allen. But when included with its Continental companies, Norba is the overall refuse vehicle leader in Europe.

The new refuse bodies are supplied by Norba's sister company in Sweden, Norba AB, and are shipped over complete with hydraulics to Hitchen where they are assembled on a variety of chassis depending on customer requirements. Norba's own MUN chassis is supplied by Shelvoke and Drewry, which is nearby at Letchworth.

Power comes from a sixcylinder Perkins — well known in the municipal market. The crew cab is rebadged as Norba's own and over 15 vehicles have been sold already to authorities ranging from Dumfries to Bath.

At one time Norba built its own chassis but by buying-in the Shelvoke PY chassis, which is designed specifically for refuse operation and in particular for off-road tip work, it has avoided all the problems and pitfalls associated with small volume specialised production lines.

Prices for the K-Series are in the region of £29,000 although Norba stresses that savings can be made by analysing payload requirements, giving as an example its 15-ton-gvw range which, with its payload of over 6.5 tons, sell at a lower price than a conventional sixteentonner. No greater payload is offered by other manufacturers.

A reduced weight would also mean lower tax and fuel bills.

Norba may not be the biggest vehicle builder in the industry, but its approach to manufacturing is a lesson that everybody in the commercial vehicle business would do well -to remember.