AN IMPROVED GAS-PRODUCER PLANT.

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

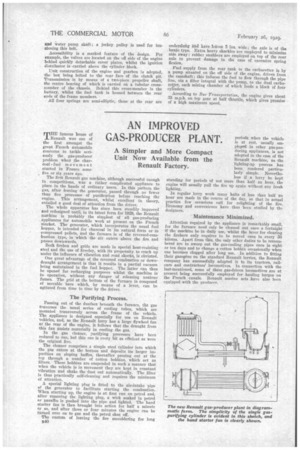

A Simpler and More Compact Unit Now Available from the Renault Factory,

TFIE famous house of Renault was one of the first amongst the great French automobile concerns to tackle seriously the gas-producer problem wherf the charcoal-fuel movement started in France some five or six years ago.

The lint Renault gas machine, although successful enough in competitions, was a rather complicated appliance to place in the hands of ordinary users. In this pattern the gas, after kaving the generator, passed through no fewer than five processes of purification before reaching the engine. This arrangement, whilst excellent in theory, entailed a good deal of attention from the driver.

The whole apparatus has since been steadily improved and redesigned until, in its latest form for 1929, the Renault matline is probably the simplest of all gas-producing appliances for automobile work at present on the French market. The generator, which incorporates the usual fuel hopper, is intended for charcoal in its natural form or in compressed pellets, and the furnace is of the reversed-combustion type, in which the air enters above the fire and passes downwards.

Both firebox and grids are made in special heat-resisting steel and the use of fireelay, with its propensity to crack up under the influence of vibration and road shocks, is obviated.

One great advantage of the reversed combustion or downdraught arrangement is that it results in a partial vacuum being maintained in the fuel hopper. The latter can thus be opened for recharging purposes whilst the machine is in operation, without any danger of releasing noxious fumes. The grid at the bottom of the furnace is composed of movable bars which, by means of a lever, can be agitated from time to time by the driver.

The Purifying Process.

Passing out of the dustbox beneath the furnace, the gas traverses the usual series of cooling tubes, which are mounted transversely across the frame of the vehicle. The appliance is designed especially for use on Renault vehicles, and, as the Renault lorry has a large flywheel fan at the rear of the engine, it follows that the draught from this fan assists materially in cooling the gas.

In the gas cleaner, purifying processes have been reduced to one, but this one is every bit as efficient as were the original five.

The cleaner comprises a simple steel cylinder into which the gas enters at the bottom and deposits its larger impurities on sloping baffles, thereafter passing out at the top through a number of cotton bobbins, which act as filters. These bobbins are suspended in such a manner that when the vehicle is in movement they are kept in constant vibration and shake the dust out automatically. The filter is thus practically self-cleaning and requires the minimum of attention.

A special lighting plug is fitted to the air-intake pipe of the generator to facilitate starting the combustion. When starting up, the engine is at first run on petrol and, after removing the lighting plug, a wick soaked in petrol or paraffin is pushed into the pipe and lighted. The hand starter fan is then brought into action for half a minute or so, and after three or fonr minutes the engine can be turned over on to gas and the petrol shut off.

The custom of leaving the fire smouldering for long p40 periods when the vehicle is at rest, usually employed in other gas-producing appliances, is not adopted in the case of the Renault machine, as the lighting-up process has been rendered particu larly simple. Neverthe less if a lorry be kept standing for periods of not more than half an hour, the engine will usually pull the fire up again without any fresh lighting.

In regular lorry work many halts of less than half an hour are made in the course of the day, so that in actual practice few occasions call for relighting of the fire. Economy and convenience have thus been studied by the designers.

Maintenance Minimized.

Attention required by the appliance is remarkably small, for the furnace need only be cleaned out once a fortnight if the machine be in daily use, whilst the lever for clearing the firebars only requires to be moved once in every 50 kilonis. Apart from this, the only other duties to be remembered are to sweep out the gas-cooling pipes once in eight or ten days and to change a cotton bobbin occasionally when one becomes clogged after long use. In addition to fitting their gazogene on the standard Renault lorries, the Renault company has successfully adapted it to its tractors, railcars and contractors' locomotives. In connection with the last-mentioned, some of these gas-driven locomotives are at Present being successfully employed for hauling barges on the French canals. Renault marine sets have also been equipped with the producer.