Doubledecke listory is Made by Guy

Page 64

Page 65

Page 66

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

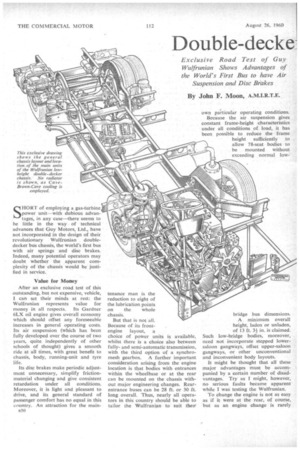

SHORT of employing a gas-turbine power unit—with dubious advantages, in any case—there seems to be little in the way of technical advances that Guy Motors, Ltd., have not incorporated in the design of their revolutionary Wulfrunian doubledecker bus chassis, the world's first bus with air springs and disc brakes. Indeed, many potential operators may doubt whether the .apparent complexity of the chassis would be justified in service.

Value for Money

After an exclusive road test of this outstanding, but not expensive, vehicle, I can set their minds at rest: the Wulfrunian represents value for money in all respects. Its Gardner 6LX oil engine gives overall economy which should offset any foreseeable increases in general operating costs. Its air suspension (which has been fully developed over the course of two years, quite independently of other schools of thought) gives a smooth ride at all times, with great benefit to chassis, body, running-unit and tyre life.

Its disc brakes make periodic adjust ment unnecessary, simplify frictionmaterial changing and give consistent retardation under all conditions. Moreover, it is light and pleasant to drive, and its general standard of passenger comfort has no equal in this country. An attraction for the maina30 tenance man is the reduction to eight of the lubrication points on the whole chassis.

But that is not all. Because of its frontengine layout, a choice of power units is available, whilst there is a choice also between fullyand semi-automatic transmission, with the third option of a synchromesh gearbox. A further important consideration arising from the engine location is that bodies with entrances within the wheelbase or at the rear can be mounted on the chassis without major engineering changes. Rearentrance buses can be 28 ft. or 30 ft. long overall. Thus, nearly all operators in this' country should be able to tailor the Wulfrunian to suit their A minimum overall height, laden or unladen, of 13 ft. 3+ in. is claimed. Such low-bridge bodies, moreover, need not incorporate stepped lowersaloon gangways, offset upper-saloon gangways, or other unconventional and inconvenient body layouts.

It might be thought that all these major advantages must be accompanied by a certain number of disadvantages. Try as I might, however, no serious faults became apparent while I was testing the Wulfrunian.

To change the engine is not as easy as if it were at the rear, of course, but as an engine change is rarely

necessary more frequently than every 200,000 miles, that is hardly a major problem. Similarly, engine noise, as heard in the lower saloon, is a little greater than with a rear-engined design, but is comparable with the volume inside the lower saloon of a conventional half-cabbed, forwardengined bus.

The air suspension is, it must be admitted, a little complicated to look at, but all linkages are rubber-bushed to avoid the need for attention at these points, and there is no reason to suspect that the air-pressure components themselves should be any more prone to trouble than those of well-tried passenger vehicles which have been operating on air springs in the U.S.A. for more than 10 years.

Because of the low frame height, rather large wheel-boxes are needed, but this is a common feature of low-bridge designs and has not necessitated raking or stepping the lower saloon gangway.

The near-side front wheelarch lies beneath the stair case, a layout which helps also to simplify passenger movement, whilst the offside wheel-box provides a luggage-stowage space 2 ft.

6 in. wide and 4 ft. 9 in. long.

Two inward facing three-passenger seats are placed over the rear wheel-arches. The foot-stools for them are about 81,in. above the level of the central

gangway, with the two pairs of forward-facing seats behind them on each side mounted on platforms of the same height.

The general specification of the Wulfrunian is by now familiar to most passenger-vehicle operators, and its layout can be seen from the accompanying exclusive drawing. Briefly, the design is built round a fabricated chassis frame of somewhat unorthodox layout, which has +-in.-thick, 8-in.deep side members, reinforced by *-in.-thick flitch plates. The main members terminate ahead of the rear axle, at which points they are bolted and welded back-to-back to curved members passing over the axle, and having bolted extension channels.

At the front of the frame the side members sweep up over the front suspension points and the near-side member is turned outwards to allow room for the front entrance. The offside member is joggled to pass along the outside of the engine, where it provides mountings also for the steering column and pedals.

The weight of the engine is shared by a cross-braced longitudinal channel, running rearwards to behind the frontsuspension line, thereby avoiding high cantilever stresses. Bolting is used throughout the assembly, and outriggers are provided for semi-integral bodywork designs.

Although the engine is offset about 16 in. to the right of the chassis centre

line, the driving position is by no means cramped, because with the standard gearbox there is no clutch pedal, and the top of the engine cowl is level with the top of the driver's seat cushion. With a synchromesh gearbox, a cable-operated gear-change linkage, with steering-columri-mounted lever, is employed_

Front and rear suspension layouts are broadly similar to those used on the airsprung Victory single-decker chassis exhibited at the 1958 Commercial Motor Show, but development work in the intervening period has produced a suspension system which could not be matched for smoothness by the majority of private, cars, whatever their cost. How the system works in detail is something the makers are not willing to have published (although it is simple to understand; once the basic principles have been grasped), but the success of the installation depends on a series of linked valves, high air pressures and wide spring bases.

Telescopic dampers assist the spring B32 units at all wheels, but the marked resistance to roll is created principally by the valves and general geometrical layout. Some pitching IS evident at times, but, as with slight roll tendencies, this is "nipped in the bud" by devices which automatically give a sharp increase in spring rate over and above the increase given naturally by an air spring. Even the nose-down attitude assumed when braking hard is corrected before the vehicle comes to rest.

Manual Braking Retained The Girling disc brakes used at each wheel have hydraulic actuation, supplemented by twin Clayton Dewandre Airpak servo units. These Airpaks are controlled by twin hydraulic master cylinders operated by a balance beam linked from the brake pedal in such a way that failure of either the air supply or one or other of the hydraulic circuits will still leave the driver with manual braking.

The use of a small transmission hand brake is another valuable safety feature, although it was adopted primarily because the hand-brake lever could not be linked to the wheel-brake calliper units. The separate drum on the nose of the rear axle gives a brake which is independent of the foot-brake system, and is powerful enough to yield 27 per cetit. efficiency when bringing a fully laden bus to rest from 20 m.p.h.

A dropped-centre rear axle, with primary-reduction gears and helical-spur secondary reduction trains, is employed to allow the low gangway height to be maintained throughout the length of the body. A choice of overall ratios is given, the ratio of the axle on the test bus being 5.6 to, 1.

The axle has a cast-steel case, but is lighter than a conventional worm axle and is quiet in operation. It might, however, be a little difficult to reach the spiral-bevel and differential gears if they required to be inspected or changed.

Twin, unequal-length wishbones carry each front wheel, and the suspension geometry provides a total vertical wheel movement of 6 in. for a change in camber angle of only r. The static camber-angle setting is 1° negative.

Rubber and Glacier DU p.t.f.e.-lead bushes eliminate the need for front suspension maintenance, whilst Burman recirculatory-ball steering gear with a ratio of 30 to 1 (eight turns from lock to lock) helps to ensure light steering at all times, despite a total front-wheel loading of more than 6 tons when fully laden.

Instead of the Gardner 6LX 10.45-litre engine, the Gardner 6LW 8.4-litre unit may be installed, as may several engines made by other vehicle manufacturers, a feature helping towards standardization in mixed fleets. For use in the Wulfruniari the 6LX is derated to produce 125 b.h.p. at 1,700 r.p.m. (instead of 150 b.h.p. in standard form) and 405 lb.-ft, torque, instead of 485 lb.-ft., at 1,000-1,100 r.p.m.

This derating is in accordance with the requirements of many passenger-vehicle operators, but its value depends on the type of service on which the bus is likely to be engaged. if heavy traffic and a large number of stops per mile are liable to be encountered, the normal rating might be more suitable for maximum economy, because, as my Access to the near side of the power unit is good, with the cowl panel adjacent to the loading platform removed. A hinged panel in the front of the bus can be opened to reach the front of the engine.

fuel-consumption results show, at six stops per mile with full load (possibly an exceptional service condition for most fleets) the fuel-consumption rate was disproportionately heavy compared with results obtained under simulated lighter conditions.

However, for normal service the 6LX shows exceptional fuel economy, both when running fully laden on lowdensity operation and when part-laden under high-density conditions.

Synchromesh Gearbox Offered

With fully, or semi-automatic gearboxes the Wulfrunian's engine carries a hydraulic coupling, whilst a normal plate clutch is used when a Z.F. synchromesh gearbox is specified. The clutch should help to improve economy still further, but with a Toss of flexibility in heavy traffic and with greater effort required from the driver. The gearbox in all cases is remotely mounted from the engine, simplifying access to engine, clutch or coupling, and gearbox.

Engine-installation space is saved by employing a Cave-Brown-Cave enginecooling and saloon-heating system. The radiator is removed from the engine compartment and two are located at the front of the upper saloon. The engine fan is retained to maintain an air flow over the cylinders and crankcase, The heating system on the test bus was not very reliable, only partially warmed air passing into both saloons despite air temperatures of about 60° F. Later models will have thermostatically Controlled radiator shutter8 reacting to saloon temperatures.

As standard equipment the B7.5 front wheels carry 11.00-20-in. (16-ply) tyres, with 9.00-20-in, (10-ply) tyres on the B7.0 rear wheels, but the chassis layout makes provision for fitting rear tyres of up to 11.00-20-in. section. The electrical system is 24v., with a C.A.V. amp, dynamo, but an alternator can be installed.

The bus tested was based on the Ant Wulirunian chassis to have been assembled on the production line, and was a demonstration model with Roe 72-seat all-metal body. The mean overall height was 13 ft. 4i in., and the loadingplatform step height was 14.1 in. when fully laden and 15 in. when empty. There were 31 seats in the lower saloon and 41 in the upper: 78-seat versions have 33 -seats on the lower deck and 45 on the Upper.

Wide Staircase

The body layout of the' test 'bus is good for a high-capacity vehicle, and the Staircase is wide and well angled for safety, although its location on the near side of the body seemed a little strange at first, Redro air-operated jack-knife doors are fitted, but these are disappointingly slow in operation. Air for these doors is supplied from the main air reservoir through a reducer valve which cuts the pressure from 150 p.s.i. (for the air suspension) to 80 p.s.i. for the brakes, gear-change servos and door mechanism.

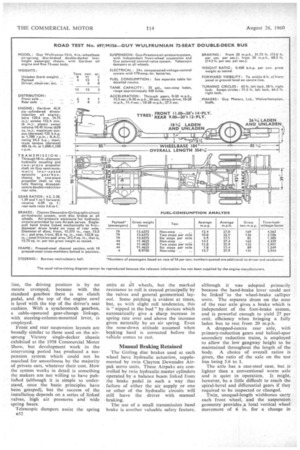

For the fully laden tests weights totalling 4 tons 151 cwt. had been placed in the body, so that with three Guy representatives and myself aboard the bus was loaded to the equivalent of 79 passengers, driver and conductor. The kerb weight was 8 tons 114 cwt, and the dry taxation weight recorded on the body side was 8 tons cwt.—very low for a bus of this capacity.

As the data panel shows, good overall braking, acceleration and fuel-consumption figures were obtained. Because rain fell during the first day's testing, the initial braking figures were taken on a wet road and averaged 38.5 ft. from 20 ni,p.h. and 81 ft. from 30 m.p.h. without any instability.

After the unladen test on the second day, the bus Was reloaded (using a fork lift truck for the upper saloon) and dryroad figures were taken. These tests gave Tapley-meter maximum-retardation readings of 64 per cent. from 20 m.p.h. and 56.5 per cent, from 30 m.p.h.—high enough for the comfort of most passengers.

During the stops-per-mile fuel tests I noted that the Guy driver was accelerat ing to 20 m.p.h. from a standstill in about 20 seconds on average, and braking at about 20 per cent. efficiency. A " crash " stop from 20 m.p.h. at the end of these runs gave more than 50 per cent, efficiency on a wet road, compared with 49 per cent, with cold discs on an equally wet road. The rear hubs were cool to the touch, indicating the effectiveness of the Guy disc motinting in preventing heat from passing into the wheel hubs.

Hermitage Hill, Br idgnorth, which is mile long

and has an average gradient of -1 in 12 and a maximum of 1 in 8, was climbed non stop in an ambient tempera ture of 57° F. The run took only 3 minutes 10 seconds.

Bottom gear was used on the steepest section for 27 seconds at a minimum road speed of 6 m.p.h. and no exhaust smoking was observed. The temperature of the water in the secondaryradiator top tank rose from 97° F. to 145° F.—the only occasion on which hot air was fed into the saloons.

Two fade tests made down the hill in neutral produced no evidence of fade at all, despite the severity of the exercise, whilst a stop-start test on the 1-in-8 section proved the hand-brake efficiency and showed that a smooth full-throttle, bottom-gear restart was possible.

Prostrated Main' tenance

Maintenance of the test bus was hampered by thoughtless body design, such as: 12 bblts to secure the gearbox inspection trap, seven for the rear-axle trap, 15 to hold down the engine-cowl panels in the driving compartment, and 10 bolts (including one with a different thread from *the 'others) to hold in place the hinged panel -which forms the front of the driving compartment.

The hinged front panel has to be opened to get to the main fuel filter on the engine, whilst all the engine-cowl

panels have to be detached for a change of injectors because ofthe need to remove the valve covers. None of these jobs was attempted, therefore, as I object to unnecessary complication..

Nevertheless, I did check the coolingsystem level at the header tank (which is mountedat loading-platform height) in 20 seconds, the engine-oil level in 16 seconds, the levels in the three brakefluid reservoirs in 27 seconds and the

levels in the four batteries in I minute 23 seconds. A trap gives access to the engine dipstick without removal of the detachable cowl panel, and the batteries are located beneath the rearmost lowersaloon seats.

The detachable cowl was removed in 20 seconds, after which I took out the Purolator paper element of the Gardner fuel filter in 16 seconds and replaced it in 25 seconds. Another 25 seconds were needed to reattach the cowl panel.

The paper-element air cleaner is easy to get at. It is carried in the body, above the off-side wheel-box, where it is housed inside a foam-plastics-lined metal box with a detachable lid: air is drawn in through a grille in the off-side panelling. The element was removed in 1 minute 22 seconds and replaced in 2 minutes.

Good handling distinguishes the Wulfrunian, so far as the driver is concerned, the steering being particularly pleasant, with just the right amout of castor action when laden or unladen, and no trace of wander. Indeed, the ride and handling do not alter at all, whether the vehicle is empty or full, and no road reaction is passed to the steering wheel, whatever the road surface. Gear changes are smooth even when the control lever is operated harshly, and the brakes are fully progressive in action.

The cab controls are well positioned and, because of the offset engine location, the driver sits closer to the body side than is normal for a heavy vehicle, 'hence he can signal boldly, -instead of with his fingertips. He sits. farther from the near-side kerb, though, which makes width judgment deceptive at first. The glass partition to his left has a sliding panel, and the complete assembly hinges upwards to facilitate the use of a hoist when removing the engine. .

My only criticism of the otherwise excellent riding characteristics concerns the slight lateral shaking that can be set up over certain surfaces when unladen. This is felt Over and behind the rear axle, and, although slight, is noticeable. Small, harsh bumps can "beat ". the suspension at times, but these would be very difficult to absorb completely, and potholes and similar irregularities which can cause real discomfort are successfully smoothed out.