STEADY

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

as she goes

Tippers do topple over. Even though today's chassis and tipping gear are probably more stable than they have ever been, the unforeseen can still happen. The ground under the vehicle can subside during tipping; a load can stick; and drivers can be careless.

Whatever the cause, the results can be disastrous.

Over the years many attempts have been made to tackle this problem. The most consistent approach has been made by the manufacturers of devices designed to help stabilise a vehicle during tipping but disturbingly, fewer developments are underway now than even a year ago. Projects have been shelved; resources have been diverted elsewhere. Initiatives seem to have been stifled by a combination of lack of finance and lack of confidence. The most encouraging news is now coming from the electronics industry: the idea is that if you can warn the driver in time of the risk of a roll-over accident, you can nip the problem in the bud. Trailer maker Crane Fruehauf has a pilot project on the verge of a launch, and a Rotherham-based company, Strawson Inclinometers, hopes to revive an existing product called the Tipsafe.

In the meantime, however, operators looking for more tangible safeguards against roll-over accidents will find their choices strictly limited.

There are some who say this shouldn't matter. Even Kerry Spencer of the Road Haulage Association's tipping group comments: "I'm not convinced that there are as many tipping accidents as the scaremongers claim. Of course there will always be some, but a lot of them can be put down to driver error or to situations where the ground has given. No amount of safeguards can prevent that."

In any case, the big tipping trailer manufacturers maintain that their equipment is more stable now than ever before. York, for instance, says that its standard air-sprung tipper axle, the TEC 2000 Series, offers the widest spring base of any tipper trailer at 1,400mm. It is claimed to offer more than 35% better roll stiffness than its nearest rival.

Crane Fruehauf, on the other hand, prefers to offer axles that are standard across its whole range of trailers. Chief engineer Jack Goodwins explains: "Stability depends on three things — the roll stiffness of tyres, the roll stiffness of the suspension, and the torsional strength of the chassis. You only need a weakness in one of them to be vulnerable."

The company has applied complex computer analysis to its designs, and claims that for the past five or six years its trailers have been as stable as it is possible to be. "The main improvements in future are likely to be in the realms of unladen weight," he says.

Nevertherless, when Commercial Motor reported on this subject just a year ago there were several promising stabiliser developments in the pipeline. What has happened to them? One of the more hopeful offerings was the hydraulic stabiliser system from NCS of Chesterfield. This Italian-built product was developed to brace the back of the chassis against the ground, and incorporated twin vertical rams with broad stabiliser feet. The prototype was supplied to local tipper operator Samuel Longsons, which had already fitted similar systems from other manufacturers.

Surprisingly, that installation remains unique. 'We thought we were on to a winner," says Graham Heath of NCS. "The response has been very disappoint ing." He accepts that the price of £3,500 was too high for the marketplace, and says he would have liked to reduce it by £1,000.

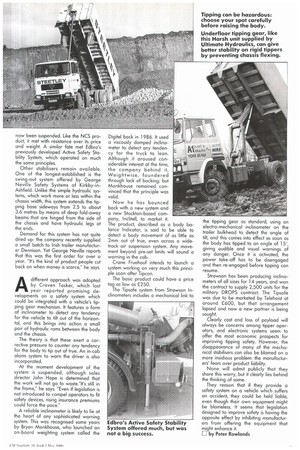

"The product is still here if anyone is interested," he adds. It is now part of the portfolio of an NCS offshoot called Truck Power Products, which also offers a range of power take-offs, and plans to launch a new Italian range of tipping gear at Tipcon. A broadly comparable stabiliser system was still being supplied last year by Drum Engineering, but work on this has now been suspended. Like the NCS product, it met with resistance over its price and weight. A similar fate met Edbro's previously developed Active Safety Stability System, which operated on much the some principles.

Other stabilisers remain available. One of the longest-established is the swing-out system offered by George Neville Safety Systems of Kirkby-inAshfield. Unlike the simple hydraulic systems, which work more or less within the chassis width, this system extends the tipping base sideways from 2.5 to about 3.6 metres by means of deep fold-away beams that are hinged from the side of the chassis and have hydraulic legs at the ends.

Demand for this system has not quite dried up: the company recently supplied a small batch to Irish trailer manufacturer Dennison. Yet George Neville reports that this was the first order for over a year. "It's the kind of product people cut back on when money is scarce," he says.

Adifferent approach was adopted by Craven Tasker, which last year reported promising developments on a safety system which could be integrated with a vehicle's tipping gear mechanism. It features a form of inclinometer to detect any tendency for the vehicle to tilt out of the horizontal, and this brings into action a small pair of hydraulic rams between the body and the chassis.

The theory is that these exert a corrective pressure to counter any tendency for the body to tip out of true. An in-cab alarm system to warn the driver is also incorporated.

At the moment development of the system is suspended, although sales director John Hope is determined that the work will not go to waste."It's still in the frame," he says. "Even if legislation is not introduced to compel operators to fit safety devices, rising insurance premiums could force the pace."

A reliable inclinometer is likely to lie at the heart of any sophisticated warning system. This was recognised some years by Bryan Monkhouse, who launched an on-board weighting system called the Digitel back in 1986. It used a viscously damped inclinometer to detect any tendency for the truck to lean. Although it aroused considerable interest at the time, the company behind it, Weightwise, foundered through lack of backing; but Monkhouse remained convinced that the principle was valid.

Now he has bounced back with a new system and a new Stockton-based company, Inclitell, to market it. The product, described as a body balance Indicator, is said to be able to detect a body movement of as little as 2mm out of true, even across a widetrack air suspension system. Any movement beyond pre-set limits will sound a warning in the cab.

Crane Fruehauf intends to launch a system working on very much this principle soon after Tipcon.

The basic product could have a price tag as low as £250.

The Tipsafe system from Strawson Inclinometers includes a mechanical link to the tipping gear as standard, using an electro-mechanical inclinometer on the trailer bulkhead to detect the angle of tilt, and this comes into effect as soon as the body has tipped to an angle of 15, giving audible and visual warnings of any danger. Once it is activated, the power take-off has to be disengaged and then re-engaged before tipping can resume.

Strawson has been producing inclinometers of all sizes for 14 years, and won the contract to supply 2,500 units for the military DROPS contract. The Tipsafe was due to be marketed by Telehoist at around £600, but that arrangement lapsed and now a new partner is being sought.

Clearly cost and loss of payload will always be concerns among tipper operators, and electronic systems seem to offer the most economic prospects for improving tipping safety. However, the disappearance of many of the mechanical stabilisers can also be blamed on a more insidious problem: the manufacturers' fears over product liability.

None will admit publicly that they share this worry, but it clearly lies behind the thinking of some.

They reason that if they provide a safety system on a vehicle which suffers an accident, they could be held liable, even though their own equipment might be blameless. It seems that legislation designed to improve safety is having the opposite effect by inhibiting manufacturers from offering the equipment that might enhance it.

II by Peter Rowlands