HINTS ON MAINTENANCE - .

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

428.—Preventing Big-end Trouble on the jB4 Tylor Engine.

One of our contributors states that, if owners of vehicles fitted with the ,D34 Tylor engine, and who have experienced big-end trouble from time to time, will, when next the engine is down or the base chain

ber dismantled, carry out ihe work which he recommends, he has no doubt that an end will be put to the trouble.

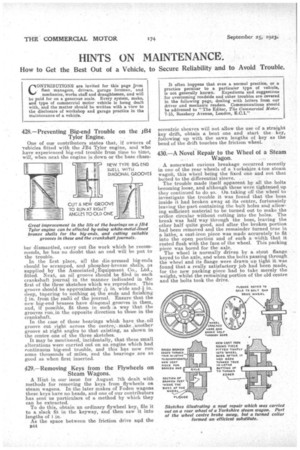

In the first place, all the die-pressed big-ends should be scrapped, and phosphor-bronze shells, as supplied by the Associated;Equiprnent Co., Ltd., fitted. Next, an oil groove -should be filed in each crankshaft journal in the manner indicated in the first of the three sketches which we reproduce. This groove should be approximately in. wide and* in. deep, tapering to nothing at the ends and finishing in. from the radii of the journal. Ensure that the new big-end brasses have diagonal grooves in them, and, if possible, fit them in such -a way that the grooves run, in the opposite direction to those in the crankshaft.

In the case of those bearings which have the oil groove cut right across the centre;.-make . another groove at right angles to that existing, as shown in the centre. one of the three sketches.

It may be mentioned, incidentally, that these small alterations were carried out on an engine which had eontinuous big-end trouble, and this has now run some thousands of miles, and the bearings are as good as when first inserted.

429.—Removing Keys from the Flywheels on Steam Wagons.

A Hint in our issue for August 7th dealt with methods for removing the keys from flywheels on steam wagons. In the later makes of Foden wagons these keys have no heads, and one of our contributors has sent us particulars of a method by which they can be extracted.

To do this, obtain an ordinary flywheel key, file it to a slack fit in the keyway, and then saw it into lengths of 1 in.

As the space between the friction drive and the 844 eccentric sheaves will not allow the use of a straight key drift, obtain a bent one and start the key, following up with the sawn lengths of key as the bend of the drift touches the friction wheel.

430.—A Novel Repair to the Wheel of a Steam Wagon.

A somewhat curious breakage occurred recently in one of the rear wheels of a Yorkalaire.4-ton steam wagon, this wheel being the fixed one and not that bolted to the differential sleeve. .

The trouble made itself apparent by all the bolts becoming loose, and although these were tightened up they continued to do so. On taking off the wheel to investigate the trouble it was found that the boss inside it had broken away at its centre, fortunately leaving the part containing the bolt holes and allowing sufficient material to be turned out to make the orifice circular without cutting into the holes. The break was half way through the boss, leaving the other half quite good, and after the broken portion had been removed and the remainder turned true in a lathe, a cast-iron piece was made accurately to fit into the open portion and of such a width that it rested flush with the face of the wheel. This packing piece was bored for the axle.

The wheel is normally driven by a stout flange keyed to the axle, and when the bolts passing through. the wheel and its flange were drawn up tight it was found that a really satisfactory job had been made, for the new packing piece had to take merely the weight, whilst the remaining portion of the old centre and the bolts took the drive.