IN

Page 36

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

VENTRE

MEDICINE

Demand for new trailers has slumped, but this has not depressed makers' inventiveness. Better aerodynamics, ingenious use of space and versatility can be seen in the new designs.

• Few would argue that this has been the worst year for the trailer industry since the start of the eighties.

Fortunately adversity stimulates inventiveness, and so far there has been an abundance of it.

Despite the diminished presence of trailer and body builders at this year's Motor Show the trend towards a greater use of aerodynamic styling was evident.

Cartwright Freight Systems has been at the forefront of the research into streamlined trailer systems together with design engineers Ricardo AS&A, along with the backing of the Department of Energy (see pages 40-41).

Peter Lane Transport is currently working with Ricardo to develop a drawbar version of the streamlined system.

Motor Show awards for ingenuity should be shared by Ray Smith and its Metroswap system, and Wilson Double-Deck's belly tanker-cum-general cargo carrier.

Under the 1.6m-high floor of Wilson's 12.2m trailer floor lies a 20,000-litre stainless steel tank with 60mrn thick all-round polyurethane foam for protection.

So far, only trailers used for carrying liquid china clay and resin have been built but managing director Fred Wilson reports considerable interest from elsewhere.

A variation on the dual theme is W&J Ridings' three-compartment trailer for solvent recycler So!rec. Its 23,000-litre central tank section sits between twin-decked box structures which each hold 40 drums.

With impending environmental demands for high-street distribution and changes in HGV licencing, the Metroswap system for trailer combinations is significant.

The first one, built for Swift Transport Systems is based on an 18.3m Mercedes drawbar outfit. Long-travel air suspension is used on the trailer which is lowered to pick up swap bodies left by 3.5 tonne chassis cabs, and then raised to the prime mover frame height. The containers are then drawn along the outfit's chassis rails using hydraulically operated skate tracking. Four 3.66m-van bodies can be trunked using this system.

If the International Road Transport Union's plea for 19m drawbars is heeded, a Metroswap outfit will be able to handle four 3.96m or five 3.20m boxes at a time as well as longer 7.62m single containers.

When 16.5m artics became the norm at the beginning of the year there were fears that car transporters would become the victims of neglect. Fortunately the Department of Transport decreed that their front swing clearance should be extended to 4.19m (compared with 2.04m for other types) and the trailers fore peak overhang could be ignored as far as outer turning circles were concerned. The lion's share of the UK car transporter market — worth about 200 units a year — usually goes to Hoynor Trailers of Braintree, Essex.

The rest is split between Charles Roberts Engineering which builds to the Austrian Kassbohrer design under licence at Wakefield, West Yorkshire, and Robert Lohr of Strasbourg, France. Walker Tridex has entered the fray with its latest air-suspended 16.5m design for 12 cars.

CRE is better known for building tankers, but makes good use of its fabrication skills to produce the Supertrans car/ commercial carrier and tri-deck drawbar outfits — both were at the NEC.

As far as transporters go, Toleman's MkV with its sophisticated electronic/ hydraulic controls has commanded the most media attention. Built in collaboration with Lohr and Iveco's Ulm truck engineers, it first appeared on the scene in January following a five-year £2.5m development programme.

Toleman's commitment is reflected in an order worth £27.5m for 226 of the MkVs which have swelled the Toleman fleet to about 500 vehicles.

One device that is claimed to make reversing drawbars much easier will be marketed in Britain early next year by IMS of Loughborough, Leics.

Swiss company George Fischer currently has a system under evaluation which evolves around a single joystick control.

SKELETALS

Although sales of skeletal trailers are slow at present there is no shortage of design application from the manufacturers.

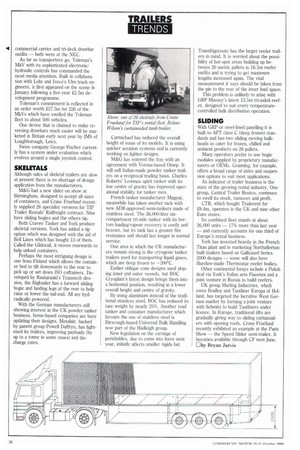

M&G had a new slider on show at Birmingham, designed to accept all sizes of containers, and Crane Fruehauf recently supplied 26 specialist versions for TIP Trailer Rentals' Railfreight contract. Nine have sliding bogies and the others tip.

Both Craven Tasker and York produce skeletal versions. York has added a tip option which was designed with the aid of Bell Lines which has bought 13 of them. Called the Gliderail, it moves rearwards to help unload containers.

Perhaps the most intriguing design is one from Finland which allows the container bed to tilt 'downwards to the rear to pick up or set down ISO containers. Developed by Rautaruuki's Transtech division, the Bigloader has a forward sliding bogie and landing legs at the rear to help raise or lower the tail-end, All are hydraulically powered.

With the German manufacturers still showing interest in the UK powder tanker business, home-based companies are busy updating their designs. Metalair, backed by parent group Powell Duffryn, has lightened its trailers, improving payloads (by up to a tonne in some cases) and discharge rates. Carmichael has reduced the overall height of some of its models. It is using quicker aeration systems and is currently working on lighter designs.

M&G has entered the fray with an agreement with Verona-based Omep. It will sell Italian-made powder tanker trailers on a reciprocal trading basis. Charles Roberts' Lowmax spirit tanker with its low centre of gravity has improved operational stability for tanker men.

French tanker manufacturer Magyar, meanwhile has taken another tack with new ADR-approved semi-tankers made of stainless steel. The 36,000-litre sixcompartment tri-axle tanker with its bottom loading/vapour recovery is costly and heavier, but its tank has a greater fire resistance and should last longer in normal service.

One area in which the UK manufacturers remain strong is the cryogenic tanker trailers used for transporting liquid gases, which are deep frozen to —200°C.

Earlier oblique cone designs used sloping inner and outer vessels, but BOC Cryoplant's latest design brings them into a horizontal position, resulting in a lower overall height and centre of gravity.

By using aluminium instead of the traditional stainless steel, BOC has reduced its tare weight by nearly 25%. Another road tanker and container manufacturer which favours the use of stainless steel is Birscough-based Universal Bulk Handling now part of the Hadleigh group.

New legislation on the carriage of perishables, due to come into force next year, initially affects smaller rigids but Transfrigoroute has the larger reefer trailers in mind. It is worried about the possibility of hot-spot areas building up between 26 metric pallets in 16.5m reefer outfits and is trying to get maximum lengths increased again. The vital measurement it says should be taken from the pin to the rear of the inner load space.

This problem is unlikely to arise with (;RP Massey's latest 13.5m tri-axled reefer, designed to suit every temperaturecontrolled bulk distribution operation.

SLIDING

With GRP or steel-lined panelling it is built to APT class C (deep frozen) standards and has two sliding moving bulkheads to cater for frozen, chilled and ambient products on 26 pallets.

Many operators prefer to use bogie modules supplied by proprietary manufacturers or OEMs. Granning, for example, offers a broad range of axles and suspension options to suit most applications.

An indicator of trailer business is the state of the growing rental industry. One group, Central Trailer Rentco, continues to swell its stock, turnover and profit.

CTR, which bought Trailerent for £9.4m, operates in the UK and nine other Euro states.

Its combined fleet stands at about 26,000 units — 17% more than last year — and currently accounts for one third of Europe's rental business.

York has invested heavily in the French Titan plant and is marketing Northallertonbuilt trailers based on Gallicised Series 2000 designs — some will also have Harelaw-made Thermostar reefer bodies.

Other continental forays include a Polish deal via York's Italian arm Piacenza and a joint venture in Russia to build reefers.

UK group Marling Industries, which owns Boalloy and Tautliner Europa of Holland, has targeted the lucrative West German market by forming a joint venture with Schmitz to build Tautliners under licence. In Europe, traditional tilts are gradually giving way to sliding curtainsiders with opening roofs. Crane Fruehauf recently exhibited an example at the Paris Show — the Speed Slider semi-trailer. It becomes available through CI' next June. Oby Bryan Jarvis