Things are lookin up on downtim

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Ford has saved hours of maintenance time on its new Cargo, but exactly how and where? To find out, Tim Blakemore saw an 0812 tipper through a simulated 18,000 nnilE service in our Workshop Ways series.

TM's 1981-82 Tables of Operating Costs running costs are broken vn into five components — fuel, lubricants, tyres, maintenance I depreciation.

t today's fuel prices you might expect fuel costs to be the greatOf these in every one of our vehicle weight categories. You'd be ing.

lften, the pence per mile figure for maintenance is slightly more I in the heavier tipper category it is significantly greater, reflecting hefty maintenance bills that can be expected for on-site vehicles. !early, then the relative cost of maintaining different makes of icle is going to be a major influence on vehicle purchasing deciis. Any manufacturer introducing a new range of vehicles must ognise this if it hopes to succeed.

3rd certainly has done so with the Cargorange. If the new range is ng to stand a chance of winning the battle implied in its slogan It To Combat Rising Costs, maintenance will have to be tightly ttrolled, :ompared with D-Series, the number of hours needed for routine vice jobs on Cargo has been considerably reduced. For example ts first 60,000km (36,000 miles), a typical Cargo with six-cylinder Docharged engine, CAV fuel injection equipment and power Bring, will need 16.5 hours of servicing time. A comparable Dies needed 48.2 hours.

.o find out where some of these hours are saved, CM has been ;k to Laidlaw (formerly Hensmans), the Ford dealer in the heart of .d country at Brentwood, Essex.

Ve followed technician Brian Jones through a simulated 000km (18,000 mile) service on an 0812 tipper Cargo. It had to be iulated — we reckon there is not a Cargo in the country that has done 30,000km.

Our Cargo was a 7.5-tonne v tipper chassis — a model offered in the D-Series ge. Torsion bar assisted cab ng to 50° is a one-man job I, unlike D-Series, no part of cab locking mechanism is ide the cab. For major repair rk, the cab can be tilted tond 50°.

The absence of a cab support iss-member over the rear of ! engine greatly improves ..essibility. Improved valve 3 r has allowed the valve clearadjustment frequency to be tended from 20,000km to 000km. The valve adjuster ew's thread is now metric — be remembered if they need fleeing.

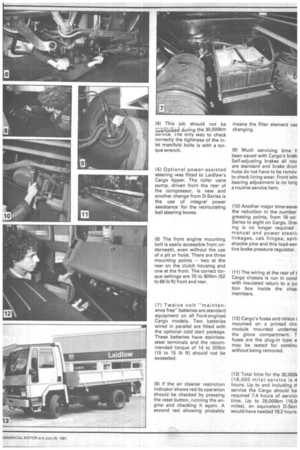

A positive displacement (pis.) type) lift-pump was fitted to ) Ford engines in the last Dries — and retained for Cargo. I Cargo one of two types may fitted — Bosch or AC Delco. e horizontal mounting of the filter makes the job of clean) it easy. (4) This job should not be

1i50-ked during the 30,000km ...ef vice. i ne only way to check correctly the tightness of the inlet manifold bolts is with a torque wrench.

(5) Optional power-assisted steering was fitted to Laidlaw's Cargo tipper. The roller vane pump, driven from the rear of the compressor, is new and another change from D-Series is the use of integral power assistance for the recirculating ball steering boxes.

(6) The front engine mounting bolt is easily accessible from underneath, even without the use of a pit or hoist. There are three mounting points — two at the rear on the clutch housing and one at the front. The correct torque settings are 70 to 90Nm (52 to 66 lb ft) front and rear.

(7) Twelve volt "maintenance free" batteries are standard equipment on all Ford-engined Cargo models. Two batteries wired in parallel are fitted with the optional cold start package. These batteries have stainlesssteel terminals and the recommended torque of 14 to 20Nm {10 to 15 lb fit) should not be exceeded.

(8) If the air cleaner restriction indicator shows red its operation should be checked by pressing the reset button, running the engine and checking it again. A second red showing probably (9) Much servicing time h been saved with Cargo's brak( Self-adjusting brakes all rou are standard and brake drurr hubs do not have to be remov to check lining wear. Front whE bearing adjustment is no long a routine service item.

(10) Another major time-saver the reduction in the number greasing points, from 18 on Series to eight on Cargo. Gre ing is no longer required manual and power steerii linkages, cab hinges, sprii shackle pins and this load-sen tive brake-pressure regulator.

(11) The wiring at the rear of t Cargo chassis is run in cond with insulated return to a jur tion box inside the chas: members.

(12) Cargo's fuses and relays E mounted on a printed circ module mounted underneE the glove compartment. T fuses are the plug-in type a may be tested for continu without being removed.

(13) Total time for the 30,000k (18,000 mile) service is 4 hours. Up to and including tlservice the Cargo should ha' required 7.4 hours of servicir time. Up to 26,000km (16,01 miles), an equivalent D-Seri. would have needed 19.2 hours