ENGINEER'S NOTEBOOK

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

converted unit. The company builds chassis in a range of lengths to suit most applications and tractors and can also adapt to individual needs, says managing director Colin Ess.

Dimensions vary to suit load requirements. The 'worst' case — a gross weight of 38 tonnes — entails a minimum length from the tractor's rear axle to the trailer's rear axle of 6.3m for a six-wheel tractor or 6.9m for a 4x2. The regs also require a minimum overall length of 12m.

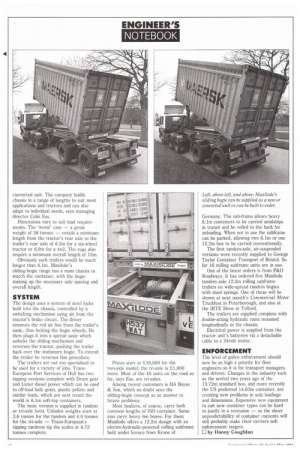

Obviously such trailers would be much longer than 6,1m. Maxilode's sliding-bogie range has a main chassis to match the container, with the bogie making up the necessary axle spacing and overall length.

The design uses a system of steel locks built into the chassis, controlled by a switching mechanism using air from the tractor's brake circuit. The driver removes the red air line from the trailer's susie, thus locking the bogie wheels. He then plugs it into a special susie which unlocks the sliding mechanism and reverses the tractor, pushing the trailer back over the stationary bogie. To extend the trailer he reverses this procedure.

The trailers are not too specialised to be used for a variety of jobs. TransEuropean Port Services of Hull has two tipping versions complete with Drum gear and Lister diesel power which can be used to off-load bulk grain, plastic pellets and similar loads, which are sent round the world in 6.1m soft-top containers.

The basic version is supplied in tandem or tri-axle form. Unladen weights start at 3.6 tonnes for the tandem and 4.0 tonnes for the tri-axle — Trans-European's tipping tandems tip the scales at 4.72 tonnes complete. two-axle model; the tri-axle is £1,000 more. Most of the 45 units on the road so far, says Ess, are tri-axles.

Among recent customers is HA Boyse & Son, which no doubt sees the sliding-bogie concept as an answer to future problems.

Most hauliers, of course, carry both common lengths of ISO container. Some also carry heavy 6m boxes. For them Maxilode offers a 12.2m design with an electro-hydraulic-powered rolling subframe built under licence from Krone of Germany. The sub-frame allows heavy 6.1m containers to be carried amidships in transit and be rolled to the back for unloading. When not in use the subframe can be parked, allowing two 6.1m or one 12.2m box to be carried conventionally.

The first tandem-axle, air-suspended versions were recently supplied to George Taylor Container Transport of Bristol. So far 16 rolling subframe units are in use.

One of the latest orders is from P&O Roadways. It has ordered five Maxilode tandem axle 12.2m rolling subframe trailers on wide-spread tandem bogies with steel springs. One of these will be shown at next month's Commercial Motor Truckfest in Peterborough, and also at the IRTE Show at Telford.

The trailers are supplied complete with double-acting hydraulic rams mounted longitudinally in the chassis.

Electrical power is supplied from the tractor unit's batteries via a detachable cable to a 24volt motor.

The level of police enforcement should now be as high a priority for fleet engineers as it is for transport managers and drivers. Changes in the industry such as the arrival two years ago of the 13.72m standard box, and more recently the US preferred 14.63m container, are creating new problems in axle loadings and dimensions. Expensive new equipment to suit new container types can be hard to justify in a recession — so the sheer unpredictablility of container contents will still probably make their carriers soft enforcement targets.

LI by Danny Coughlan