STEAM-WAG()

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

BODYWORK

DURING the past year or two the driver's cab of the steam wagon has undergone several modifications. The improvements effected have been the result of a desire to give better protection to the driver now that a speed up to 20 m.p.h. is permissible for vehicles with pneumatic tyres.

The cab is often fully enclosed with full-height doors, an adjustable glass windscreen and comfortable cushions, making a strong contrast with the older pattern with only a canopy overhead.

The design of the cab also varies according to the position of the engine, boiler, controls and coal bunker. A vertical boileir is mounted inside the front end of the chassis and the cab is sufficiently wide to enable the driver and fireman, sitting behind and on each side of the boiler, to have a clear view ahead.

The space between the boiler and the side of the cab or fender panel may be used for a coal bunker, or, on the off side, the opportunity may be taken for placing the steering control well forward. The driver's outlook is thus improved and, if necessary, the overall length of the cab may be reduced.

Now that the cab is enclosed the bunker is often placed between the driver's and fireman's seats, with the advantage that the bunker may be extended to the bottom of the back window, or, if extra capacity be desired, even to the roof. The bunker may also be behind or under either seat, but easy access for the driver is necessary if the vehicle is to be one-man controlled.

The observational value of the cab Is increased if the engine be under the chassis, although when the steering wheel is at the side, rather than behind a compactly designed unit mounted on a locomotive-type boiler, the accessibility of the engine may be considered to compensate for any obstruction that it may form. Alternatively, the engine may be behind the boiler, so that it is between the cab seats.

At the present time it is most general to 3332 find the umiertype mounting for the engine ; as a consequence the cab provides the maximum amount of visibility. Even the funnel need be no obstruction, because it is possible for this to he at the back of the cab.

With the funnel in its usual position the windscreen . may he either in front or behind it. The screen is usually vee-shaped or semi-hexagonal in plan. It is then. close to the driver, and the sides of the cab may converge to the front.

If the seats be fixed, or the space under them be required for lockers or bunkers, the door is above the front wheel, but, if the seats be hinged, it is possible to arrange a wider and more easily reached door farther back. Sliding or winding windows may be adopted, but the former are more suitable for signalling.

Apart from the adjustment of these windows and the upper panels of the windscreen, there should be an efficient scheme of ventilation.

This may consist of louvres above the screen and under the roof at the sides, one or two air extractors or flap-type ventilators in the roof. The side louvres may have movable panels at the back in order that the degree of ventilation may be varied. It is also desirable to have ventilators in the fender panel.

The cab framework is of hardwood supported on cross-bearers on which are secured the bottom sides. Into these are mortised the pillars which form the framework of the side windows and door openings, and support the roof. The back of the cab is matchboarded and the side panelling is of wood and metal. The footplate forms the floor, and it is usual to cover the cab roof with sheet metal.

The steam wagon, being a vehicle for the heavier class of transport, requires a substantial bottom framework for the loading portion. Cross-bearers, if made of softwood, will not necessarily break, but they will suffer under compression and set 1117) distortion. The oak or ash bearers are clipped to the chassis by means of stirrup plates

The floorboards are grooved and separate hardwood tongues are inserted, these giving greater strength than do tongues which are formed solid with the boarding.

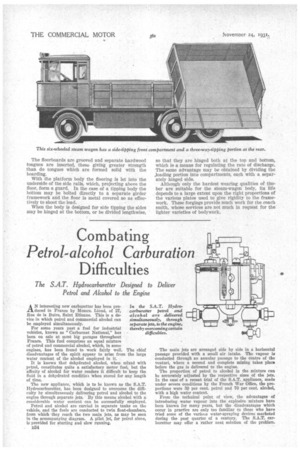

With the platform body the flooring is let into " the underside of the side rails, which, projecting above the floor, form a guard. In the case of a tipping body the bottom may be bolted directly to a separate girder framework and the floor is metal covered so as effectively to shoot the load.

When the body is designed for side tipping the sides may be hinged at the bottom, or be divided lengthwise, so that they are hinged both at the top and bottom, which is a means for regulating the rate of discharge. The same advantage may be obtained by dividing the ,loading portion into compartments, each with a separately hinged side.

Although only the hardest wearing qualities of timber are suitable for the steam-wagon body, its life depends to a large extent upon the right proportions of the various plates used to give rigidity to the framework. These forgings provide much work for the coach smith, whose services are not much in request for the lighter varieties of bodywork.