Single-drive with bogie lift con beat double-drive for grip

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

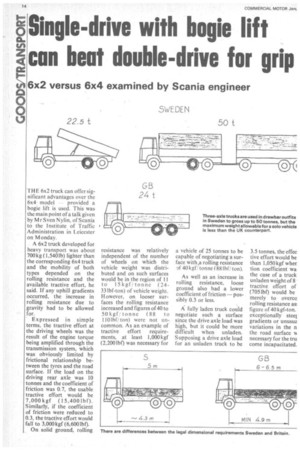

6x2 versus 6x4 examined by Scania engineer

THE 6x2 truck can offer significant advantages over the 6x4 model -provided a bogie lift is used. This was the main point of a talk given by Mr Sven Nylin, of Scania to the Institute of Traffic Administration in Leicester on Monday.

A 6x2 truck developed for heavy transport was about 700 kg (1,5401b) lighter than the corresponding 6x4 truck and the mobility of both types depended on the rolling resistance and the available tractive effort, he said. If any uphill gradients occurred, the increase in rolling resistance due to gravity had to be allowed for.

Expressed in simple terms, the tractive effort at the driving wheels was the result of the engine torque being amplified through the transmission system, which was obviously limited by frictional relationship between the tyres and the road surface. If the load on the driving rear axle was 10 tonnes and the coefficient of friction was 0.7, the usable tractive effort would be 7,0 00 kgf (15,40 Olbf). Similarly, if the coefficient of friction were reduced to 0.3, the tractive effort would fall to 3,000 kgf (6,600 lbf).

On solid ground, rolling resistance was relatively independent of the number of wheels on which the vehicle weight was distributed and on such surfaces would be in the region of 11 to 15 kgf/ tonne (2433 lbf-ton) of vehicle weight. However, on looser surfaces the rolling resistance increased and figures of 40 to 50 kgf; tonne 188 to 1101bf/ ton) were not uncommon. As an example of tractive effort requirements, at least 1,000 kgf (2,2001bf) was necessary for a vehicle of 25 tonnes to be capable of negotiating a surface with,a rolling resistance of 40 kgf' tonne (881bl/ton).

As well as an increase in rolling resistance, loose ground also had a lower coefficient of friction — possibly 0.3 or less.

A fully laden truck could negotiate such a surface since the drive axle load was high, but it could be more difficult when unladen. Supposing a drive axle load for an unladen truck to be 3.5 tonnes, the effec tive effort would be than 1,050 kgf wher tion coefficient wa the case of a truck unladen weight of 8 tractive effort of (705 lbf) would be merely to overco rolling resistance as figure of 40 kgf-ton. exceptionally steer gradients or unusua variations in the n the road surface A; necessary for the tru come incapacitated. figures referred to in a general sense, the case for 6x4 (2 models could be long the same lines. 6x4 truck the load . approximately 50le bogie axles. For , for a fully laden a bogie load of 18 operating in as with a coefF friction of 0.3, the 'active effort would ound 5,400 kgf )0.

6x2 vehicle the load normally around 53 on the drive axle. Under the same operating conditions the usable tractive effort in this case would be around 2,860 kgf (6,400 lbf). Thus at a gross weight of 24 tonnes, both trucks could negotiate such a surface even if the rolling resistance were as high as 80 kgf/ tonne (176 lbfl ton).

For unladen trucks, however, the position was very different, said Mr Nylin. As an example, if each vehicle had a bogie load of 4 tonnes and a kerb weight of 8 tonnes, the usable tractive effort on the 6x4 model would be about 1,200kgf (2,650Ibf) compared to 635 kgf (1,4251bf) for the 6x2. In such conditions the 6x2 truck could be in serious difficulty and this was where bogie lift came into the picture.

As its name suggested, bogie lift meant raising the trailing axle off the ground, usually by hydraulic means, which put the whole of the bogie load onto the drive axle. This reduced the front axle loading. In the case considered earlier, if it was assumed that one additional tonne was transferred to the drive axle by this method, then the load on this axle would increase by 5 tonnes and the usable tractive effort would increase to 1,500 kgf (33001bf), which was about 300 kgf (6601b0 better than the 6x4 in the same situation.

Another advantage of the bogie lift was a "reduction" in the wheelbase of the vehicle. When the trailing axle was raised the truck became, in effect, a two-axle vehicle, and owing to this shorter wheelbase the turning circle would be reduced.