Solving the Fleet Operator's

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

SPARE-WHEEL PROBLEMS

'

T

. IIE statement that it is necessary to carry a stock of spare wheels

' and equipment may, to the fleet operator, seem superfluous, but the need for spares covers a far wider ground than the obvious one namely, replacing a wheel when serious trouble develops. Not only are the causes of wheel failure many, but also they are• largely preventable by carrying wheels and wheel equipment that will cover any emergency. . . The purpose of this article is to deal with 'methods by which the minimum. expenditure on spares can be incurred with the maximum benefit, to show how the judicious use of spares can effect an economy, and how an efficient .service, with freedom from road trouble, can be maintained. The use of spare wheels is not simply that of emergency ; in fact, if they be used correctly, and a proper system be established, wheel troubles on the road . will be rare.

• However, let us first discuss the emergency angle. A vehicle comes into the garage after a day's run, needing wheel replacement, and if the required spare be not on hand it is out of service until the new wheel can be obtained. Calls from drivers in :trouble on the road must be met with an immediate response, and render indispensable, in the ' case of large . operators. a service van which will be driven . by a mechanic capable of rectifyingthe troulAe and, of course, of fitting a new wheel.

Value of a Service Van.

Even small operators who rely on help from the nearest garage will find it less' expensive to run a service van of their own. Van and driver will probably pay for themselves within a year.

Turning to a consideration of stock, an adequate supply of studs and nuts is of first importance, and it is no exaggeration to say that if new studs and nuts be fitted in time, the cost of a new wheel may be avoided, because when studs get old, due to various causes, the threads wear down. This means that the cone nut cannot obtain a proper grip, and will, therefore, slacken. Consequently, looseness results, the stud holes become elongated or out of shape, and the wheel is rendered useless. If the wheels be regularly examined, and new studs and nuts be fitted as the first signs of wear become apparent, the cost of a new wheel will be avoided.

Correctly used and serviced, the wheel will last as long as the vehicle. A wheel failure on the road, brought about by elongation of the stud holes, which should never have been allowed to develop, may be the direct cause of e.28 loss due to delay in delivery of a load and to the time expended by the driver and the service vehicle. This would have been avoided had the studs and nuts been subjected to a regular and systematic overhaul.

Wheel Interchangeability..

Many fleet operatorsto-clay run vehicles of similar type, and, almost without exception, all fleets incluae three or four vehicles of the same make and model. In reviewing the question of interchangeability of wheel equipment, however, it is best to divide the vehicles into categories of loadcapacity. The operator who owns, say. four 2-ton vehicles, four 3-ton and four 4-5-ton vehicles will find it economical to run each category on similar wheels, thus reducing the variety of spares he needs to hold.

Even if the make of vehicle be different, it is possible to use the same type of wheel. To provide all-round.' interchangeability, it is usual to fit singles on the front axle and twins on the rear, employing wheels with the same offset, or dish. Assuming that all vehicles of similar carrying capacity have the same wheel equipment, one or two spares in the garage (which should he replaced immediately one is used) will meet all likely emergencies.

It is hardly necessary to add that where vehicles have front wheels which differ from those at the rear, it is advisable to change over to similar wheels so soon as possible.

Equipment for Various Capacities of Vehicle.

The following examples will prove helpful. Dividing the vehicles into their various groups, we have the following :

30-40-cwt. class : Usually this type of vehicle will be fitted with 6.00 by 20 T. and B. tyres, or the 32 by 6 T.T. tyres, twin rears and single fronts. A. better mileage will, of course, be obtained from the 32 by 6 H.D. tyre. but whichever the operator favours, it will be to his advantage to standardize that type on all vehicles. These tyres will be fitted on machines such as the Fordson and Dodge vehicles, on fivestud disc wheels, whilst on Reos a fivestud wheel with a different drilling is used. An eight-stud wheel drilled for 18-mm: studs is the general fitting en Dennis, Albion, Commer, MorrisCommercial and Leyland chassis,

whilst on the Bedford there are 'eightstud wheels with special drilling.,

50-70-cwt. class : The tyre equipment in this class is generally 82 by 6 H.D. or 84 by 7 RD., and for many reasons the latter size is preferable., The drilling is usually the same as that in the 20-40-cwt. class, but the wheels are, of course, made for the larger tyre and have a bigger offset.

. On this size of vehicle many users fit the 32 by 6 T.T. tyre on the front wheels, to prevent steering from becoming too heavy. As the load is chiefly on the rear axle, this is a satisfactory arrangement, and it saves a certain amount in tyre costs. The wheels used are the same; thus interchangeability is not affected. Moreover, as the larger tyre can, in emergency, be used for a front wheel —long enough, at least, for the vehicle to be driven home—a spare thus equipped is sufficient. •

4-5-ton class : These vehicles . will usually be fitted with 8-in. tyres all round. Most later models have 36 by 8 tyres on 20-in, diameter wheels or 38 by 8 tyres on 22-in, diameter w4els, due to the modern trend towards reducing loading height. On older vehicles the 40 by 8 tyres on a 24-in. wheel is usual. It is necessary to point out that, in this class, brake drums have been reduced in diameter to allow :the employment of the smaller wheel. Most of these vehicles have ten-stud

wheels drilled for B.S.F. studs. To allow interchangeability here, and in view of the three popular wheel diameters already mentioned, it will usually be found economical to consult the tyre manufacturer on the•question

of standardizing the wheels. In this respect the diameter of the brake drum is most important, and is one that gives rise to most troubles.

The above-mentioned sizes will enable the operator to select his spares to the best advantage, but consideration must be given also to drilling and offset.

Tyres for Multi-wheelers.

On six and eight-wheeled outfits it is desirable to ensure that the wheels on the trailer or semi-trailer, if these be singles, have the same offset and drilling as those on the tractive unit, so that only one spare will be required. The trailer should also have wheels shod with :similar tyres and having an Offset large enough for twins, if neces

nary. Furthermore, on vehicles with large single tyres at the rear, it is wise to specify when ordering that the wheels should have the same offset and drilling as those on other vehicles already in use, thus helping standardization.

Another point of considerable importance is that chassis now equipped with 18-mm. wheel studs can easily have these replaced by. -in. B.S.F. studs (general on new models) by using

studs with B.S.F. inserted and 18-mm. projecting portions. This avoids the necessity of opening out the stud-holes on the hub flanges. These studs can be purchased from specialists in this form of repetition work and from tyre manufacturers at about is. (Id, each.

When purchasing new vehicles it is always advisable to consult the tyre manufacturer in order to obtain the least costly standardization of wheel

equipment. Most vehicles are available with a number of specified tyres and. wheels. It should be added that care must be taken to ensure that the wheels are suitable for the varioussized tyres ; makeshift fittings will

always lead to trouble. If twins be used, the correct offset must also be ensured, otherwise the tyres may rub together in service, creating friction and overheating, which quickly lead

to tyre failure, Wheels can be obtaMed with rim and disc in one piece, this giving the maximum brake-drum clearance, whilst being as light as possible in order to come within certain taxation limits.

It is safe to say that attention to these details will simplify running conditions, will effect economy, and will reduce road trouble to a minimum.

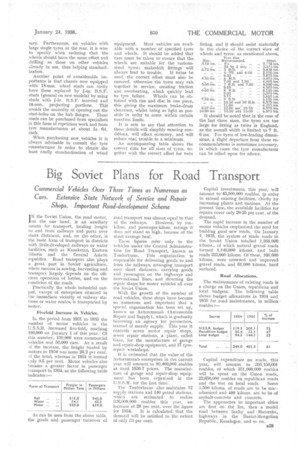

An accompanying table shows the correct rims for all sizes of tyres, together with the correct offset for twin fitting, and it should assist materially in the choice of the correct sizes of wheels and tyres, as mentioned above, Tyre Size