FORESIGHT IN HEAVY VEHICLE DESIGN.

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

-low Modern Designers are Studying the User's Convenience. Making it Easy to Keep a Vehicle in Good Repair. Accessibility Which Saves s. d. Points the Practical Man Appreciates.

IT WAS generally agreed that the heavy vehicles exhibited at the October Show fully maintained the high standard which has come to be ex?ected from British utility vehicle. designers. If imongst the many excellent machines displayed. there were no very startling innovations to record, .t was largely because such a high standard of conitruction had been reached already. At one time it rather looked as though the insistent. aarrotecry of " massed production" would force the. mdustry's engineers to design" for the factory rather than for the road. That is to say, that they would levote nearly all their attention to designing every. aart of the vehicle BO that it could be made rapidly md cheaply, and that, in consequence, they might aeglect other considerations in design, such as iccessibility and so on. Such has not, however., proved to be the case, fortunately for the industry.

As a matter of fact, after a careful survey of the xhibits at the Car Show, the writer is inclined to the opinion that, if anything, the heavy vehicle de;igner of the present day gives greater considera;inn to the user's requirements in his design than 10e8 his ear-designing confrere. Cars must mostly )e made in quantity or not at all, and the man who lesigme a ear has to have a wary eye on the machine ;hop all the time. He gives the user as much aecessiaility as he can, but he seldom sacrifices manufacturing economy in order to do so.

The heavy vehicle designer, on the other hand, knows that inaccessibility, which may merely cause annoyance to the owner of a motorcar, will meat 2 s. d. to the owner of a lorry. It is a very vital matter, and probably for that reason it receives the careful attention which is now given to it

Foresight in Design.

The success of any heavy vehicle, from the user's point of view, depends very largely upon the amount of foresight which has been exercised by the designer. The successful designer must be able to look ahead and foresee the difficulties which the user is likely to experience. Naturally, to enable him to do so, the designer needs a good deal of practical experience himself. He must know the ins and outs of the repair shop, and possess a complete road sense. It is not a matter for the theorist, pure and simple. -From this point of view the heavy vehicle industry seems to be singularly fortunate in having the designers which Fate has given it. The general accessibility of the modern machine —of, in fact, nearly all modern machines— is almost beyond reproach. In the writer's opinioe the standard set is far. higher than that in touring car design. As evidence of this, it may be both interesting and instructive to review some of the features of modern accessibility, as exemplified in vehicles which are already in the user's hands. The accessible oil filter on the 21 ton Guy, showing cap removed and filter withdrawn.

chines under repair-shop conditions affords a far better opportunity of weighing up the merits of the design from the user's point of view than any amount of casual external examination.

As has already been stated, it is largely a ease of practical foresight, and we will later examine to what extent that has been exercised.

• Two Kinds of Accessibility.

We must first appreciate the fact that there are two kinds of accessibility to be considered. There is the accessibility which consists of ease of access to all parts which require inspection or attention as part of the ordinary routine of operation. Such features as lubrication filling points, brake adjustments, and so on come under this heading. Then there is accessibility from the repair-shop point of view, which means ease of dismantlement and access to interior parts which may possibly, in ,course of time, sustain wear or damage, and which must, in any case, be inspected—if only as a formality—during a complete overhaul.

Both kinds of accessibility are mainly important from. a time-saving point of view It is obviously desirable to reduce the time necessary for daily or weekly lubrication and adjustment to the minimum, and to ensure that it is fairly easily carried out, so that a lazy driver will not be inclined to neglect these important duties. Time-saving in the repair shop is not only a matter of reducing labour costs, but it is equally important from the point of view of minimizing the losses due to the enforced inactivity of the vehicle.

Having said which, we will review briefly some of the ways in which these desiderata .have been obtained.

Lightening the Driver's Job.

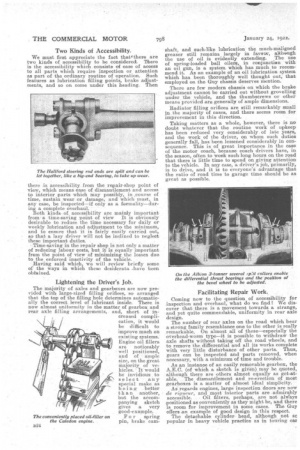

The majority of axles and gearboxes are now provided with large-sized filling orifices, so arranged that the top of the filling hole determines automatically the correct level of lubricant inside. There is now almost uniformity in the matter of gearbox and rear axle filling arrangements, and, short of increased complication, it would be difficult to improve much on existing systems. Engine oil fillers are noticeably well positioned., and of ample size, on the great majority of vehicles. It would be invidious to select any special make as being better than another, but the aecompanying sketch gives a very good .example. shaft, and such-like lubrication the much-maligned greaser still remains largely in favour, although the use of oil is evidently extending. The use of spring-loaded ball oilers, in conjunction with an oil gun, is a system which has much to recommend it. As an example of an oil lubrication system which has been thoroughly well thought out; that employed. on the Guy chassis deserves mention.

There are few modern chassis on which the brake adjustment cannot be carried out without grovelling under the vehicle, and the thumbscrews or other means provided are generally of ample dimensions.

Radiator filling orifices are still remarkably small in the majority of cases, and there seems room for improvement in this direction.

Taking matters as a whole, however, there is no doubt whatever that the routine work of upkeep has been reduced very considerably, of late years, and the work of the driver, on whom such duties generally fall, has been lessened considerably in consequence. This is of great importance in the case of the motor coach, because coach drivers have, in the season, often to wonk such long hours on the road that there is little time to spend on giving attention to the vehicle. In any case, a driver's job, primarily, is to drive, and it is to everyone's advantage that the ratio of road time to garage time should be as great as possible.

Facilitating Repair Work.

Coming now to the question of accessibility for inspection and overhaul, what do we find? We discover that there is a movement towards a strange, and yet quite commendable, uniformity in rear axle design.

The number of rear axles on the road which bear a strong family resemblance one to the other is really remarkable. On almost all of these—especially the overhead-worm type—it is possible to withdraw the axle shafts without taking off the road wheels, and to remove the differential and all its works complete with very little disturbance of other parts. Thus, gears can be inspected and parts removed, when necessary, with a minimum of time and trouble.

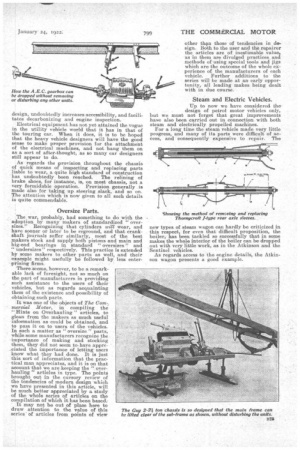

As an instance of an easily removable gearbox, the A.E.C. (of which a sketch is given) may be quoted, although there are others almost equally as get-atable. The dismantlement and re-erection of most gearboxes is a matter of almost ideal simplicity.

As regards engines, large inspection doors are now de rigueur, and most interior parts are .admirably accessible. • Oil filters, perhaps, are not always positioned as conveniently as they might be, and there is room for improvement in some cases. The Guy offers an example of good design in this respect..

The detachable cylinder • head, although not se popular in heavy vehicle practice as in touring car design, undoubtedly increases accessibility, and facilitates decarbonizing and engine inspection.

Electrical equipment has not yet attained the vogue in the utility vehicle world that it has in that of the touring car. When it does, it is to be hoped that the heavy vehicle designers will have the good sense to make proper provision for the attachment of the electrical machines, and not hang them on as a sort of after-thought, as so many car designers still appear to do.

As regards the provision throughout the chassis of quick means of inspecting and replacing parts liable to wear, a quite high standard of construction has undoubtedly been reached. The relining of brake shoes for instance, is, on most chassis, not a very formidable operation. Provision generally is made also for taking up steering slack, and so on. The attention which is now given to all such details is quite commendable.

Oversize Parts.

The war, probably, had something to do with the have sooner or later to be reground, and that crankmakers stock and supply both pistons and main and big-end beatings in standard " oversizes " and " undersizes" respectively. This practice is extended prising firms.

shaft journals suffer similarly, most of the best by some makers to other parts as well, and their example might usefully be followed by less enteradoption by many makers of standardized "oversizes." Recognizing that cylinders will wear, and

have sooner or later to be reground, and that crankmakers stock and supply both pistons and main and big-end beatings in standard " oversizes " and " undersizes" respectively. This practice is extended prising firms.

shaft journals suffer similarly, most of the best by some makers to other parts as well, and their example might usefully be followed by less enteradoption by many makers of standardized "oversizes." Recognizing that cylinders will wear, and

There seems, however, to be a remarkable lack of foresight, not so much on the part of manufacturers in prOviding such assistance to the users of their vehicles, but as regards acquainting them of the existence and possibility of obtaining such parts_

It was one of the objects of The Corn; rnereial Motor, in compiling the " Hints on Overhauling " articles, to glean from the makers as much useful information as could be obtained, and to pass it on to users of the vehicles. In such a matter as " oversize "parts, while some manufacturers recognize the importance of making and stocking them, they did not seem to have appre-eiated the importance of letting users know what they had done. It is just this sort of information that the practical man appreciates, and it is on that account that we are keeping the " overhauling " articles in type. The points brought out in the cursory review of the tendencies of modern design which we have presented in this article, will be much better appreciated by a study of the whole series of articles on the compilation of which it has been based.

• It may not be out of place here to draw attention to the value of this series' of articles from points of view other than those of tendencies in design. Bah to the user and the repairer the articles are of inestimable value, as in them are divulged practices and methods of using special tools and jigs which are the outcome of the whole experience of the manufacturers of each vehicle. Further additions to the series will be made at an early opportunity, all leading makes being dealt with in due course.

Steam and Electric Vehicles.

Up to now we have considered the design of petrol motor vehicles only, but we must not forget that great improvements have also been carried out in connection with both steam and electrically propelled machines. For a long time the steam vehicle made very little progress, and many of its parts were difficult of access, and consequently expensive to repair. The new types of steam wagon can hardly be criticized in this respect, for even that difficult proposition, the boiler, has been tackled so successfully that in some makes the whole interior of the boiler can be dropped out with very little work, as in the Atkinson and the Sentinel vehicles.

As regards access to the engine details, the Atkinson wagon presents a good example.