The spring brake system

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

IN THE middle 1960s there were a number of cases of , heavy vehicles running away because of lack of pressure in the air brake system.

In one case a cement mixer had been left overnight on a hill so that the driver could get an easy start by running down the hill in the morning. He started the engine in this way but, because there was no air pressure, the lorry got out of control and collided with a Mini. An infant was rescued, but both its parents were killed.

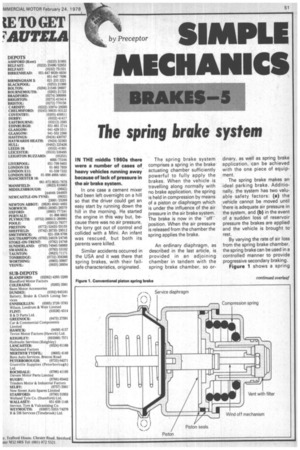

Similar accidents occurred in the USA and it was there that spring brakes, with their failsafe characteristics, originated. The spring brake system comprises a spring in the brake• actuating chamber sufficiently powerful to fully apply the brakes. When the vehicle is travelling along normally with no brake application, the spring is held in compression by means of a piston or diaphragm which is under the influence of the air pressure in the air brake system. The brake is now in the "off" position. When the air pressure is released from the chamber the spring applies the brake.

An ordinary diaphragm, as described in the last article, is provided in an adjoining chamber in tandem with the spring brake chamber, so or

dinary, as well as spring brake application, can be achieved with the one piece of equipment.

The spring brake makes an ideal parking brake. Additionally, the system has two valuable safety factors: (a) the vehicle cannot be moved until 'there is adequate air pressure in the system, and (b) in the event of a sudden loss of reservoir pressure the brakes are applied and the vehicle is brought to rest.

By varying the rate of air loss from the spring brake chamber, the spring brake can be used in a controlled manner to provide progressive secondary braking.

Figure 1 shows a spring brake with the spring compressed by a piston sliding in a machined bore. It will be seen that there is a manually operated wind off mechanism to release the brakes in an emergency when there is no air pressure, eg when the vehicle has broken down and it is necessary to tow it.

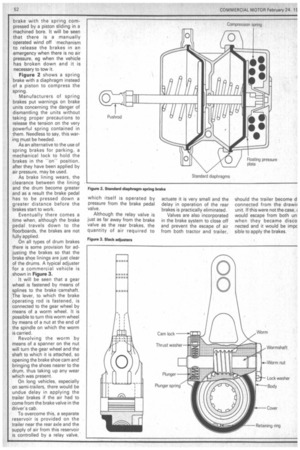

Figure 2 shows a spring brake with a diaphragm instead of a piston to compress the spring.

Manufacturers of spring brakes put warnings on brake units concerning the danger of dismantling the units without taking proper precautions to release the tension on the very powerful spring contained in them. Needless to say, this waring must be heeded.

As an alternative to the use of spring brakes for parking, a mechanical lock to hold the brakes in the "on— position, after they have been applied by air pressure, may be used.

As brake lining wears, the clearance between the lining and the drum become greater and as a result the brake pedal has to be pressed down a greater distance before the brakes start to work.

Eventually there comes a time when, although the brake pedal travels down to the floorboards, the brakes are not fully applied.

On all types of drum brakes there is some provision for adjusting the brakes so that the brake shoe linings are just clear of the drums. A typical adjuster for a commercial vehicle is shown in Figure 3.

It will be seen that a gear wheel is fastened by means of splines to the brake..camshaft. The lever, to which the brake operating rod is fastened, is connected to the gear wheel by means of a worm wheel, It is • possible to turn this worm wheel by means of a nut at the end of the spindle on which the worm is carried.

Revolving the worm by means of a spanner on the nut will turn the gear wheel and the shaft to which it is attached, so opening the brake shoe cam and bringing the shoes nearer to the drum, thus taking up any wear which was present On long vehicles, especially on semi-trailers, there would be undue delay in applying the trailer brakes if the air had to come from the brake valve in the driver's cab.

To overcome this, a separate reservoir is provided on the trailer near the rear axle and the supply of air from this reservoir is controlled by a relay valve, which itself is operated by pressure from the brake pedal valve.

Although the relay valve is just as far away from the brake valve as the rear brakes, the quantity of air required to actuate it is very small and the delay in operation of the rear brakes is practically eliminated.

Valves are also incorporated in the brake system to close off and prevent the escape of air from both tractor and trailer, 'should the trailer become d connected from the drawir unit. If this were not the case, would escape from both un when they became disco nected and it would be impc sible to apply the brakes.