A SPECIAL FIXING FOR POLACK TIRES.

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

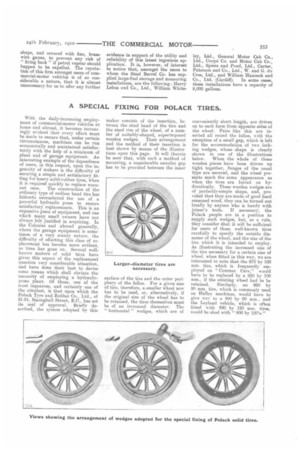

With the daily-increasing employment of commercial-motor vehicles at home and abroad, it becomes increasingly evident that every effort must be made to ensure that, under certain circumstances, machines can be run economically and maintained satisfactorily with the help of a. minimum of plant and of garage equipment. An interesting example of the dependence of users, in this respect, upon the ingenuity of makers is the difficulty of securing a simple and satisfactory fitting for heavy solid-rubber tires, when it is required quickly to replace wornout ones. The construction of the ordinary type of endless band tire has hitherto necessitated the use of a powerful hydraulic press to ensure satisfactory replacements. This is an expensive piece of equipment, and one which many small owners have not always felt justified in acquiring. In the Colonies and abroad generally, where the garage equipment is sometimes of a very scanty nature, the difficulty of effecting this class of replacement has become more evident, as time has gone on. Several wellknown makers of solid tires have given this aspect of the replacement question very considerable attention, and have done their best to devise some means which shall obviate the necessity of employing a hydraulicpress plant. Of these, one of the most ingenious, and certainly one of the simplest, is that upon which the Polack Tyre and Rubber Co., Ltd., of 31-34, Ba..singhall Street, E.C., has set its seal of approval. Briefly described, the system adopted by this maker consists of the insertion, between the steel band of the tire and the steel rim of the wheel, of a number of suitably-shaped, superimposed wooden wedges. Their arrangement and the method of their insertion is best shown by means of the illustrations upon this page. It will therein be seen that, with such a method of mounting, a considerable annular gap has to be provided between the inner surface of the tire and the outer periphery of the felloe. For a given size of tire, therefore, a smaller wheel now has to be used, or, alternatively, if the original size of the wheel has to be retained, the tires themselves must be of an increased diameter. The " horizontal " wedges, which are of

conveniently short length, are driven on to each form from opposite sides of the wheel. Pairs like this are inserted all round the felloe, with the exception of a small gap, which is left for the accommodation of two locking wedges, whose shape is clearly shown in one of the illustrations below. When the whole of these wooden pieces have been driven up tight together, flanges of the usual type are secured, and the wheel presents much the same appearance as when the tires are forced on hydraulically. These wooden wedges are of perfectly-simple shape, and, provided that they are made of good hard seasoned wood, they can be turned out locally by anyone who is handy with joiner's tools. If necessary, the Polack people are in a position to supply such wedges, but, as a rule, they consider that it will be sufficient for users of these well-known tires carefully to specify the outside diameter of the wheel, and the size of the tire which it is intended to employ. As illustrating the increased size of the tire necessary for a certain size of wheel, when fitted in this way, we are interested to note that the 870 by 100 mm. tire, which is frequently employed on " Commer Cars," would have to be replaced by a 920 by 100 mm., if the existing wheel had to be retained. Similarly, an 860 by 90 mm. tire, which is commonly used on Halley machines, would have to give way to a 900 by 90 mm., and the Leyland vehicle, which is often fitted with 830 by 120 rani. tires, would be shod with " 900 by 120's."