Record Tests with a Paraffin Tractor.

Page 3

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

100-mile Road Trial with a Marshall Military Motor.

Homoe," writing of the relative rates of the efficiencies of steam and paraffin vehicles, in a letter which appeared in our last week's issue, stated that" If tractors with trailers were permitted by law to travel at a. higher speed than five m.p.h., the petrol tractor would sweep the board as it has outstripped the steam wagon." We do not intend to give our unqualified support to that statement, because we well know that both steam and petrol machines have their limitations: steam by reason of the necessity to take up water at frequent intervals; petrol because that class of fuel is not always available, and especially is this so in many countries abroad " Hornoc " may return to the charge and say—" Use paraffin." Well, he may do so in many parts of the world, but not in England or Canada, where the difference between the prices of petrol and paraffin are not sufficiently great to warrant the employment of a heated chamber, with its attendant difficulties in connection with the adjustment of the mixture, and the maintenance of a temperature suitable for the proper vaporization of the fuel. We do not, at the present time, propose to deal with the general subject of steam engines versus internal-combustion motors, for motor vehicle propulsion, but to place before our readers the log of a record run with an internal-combustion-engined tractor which has practically made a non-engine-stop run of 100 miles, at the same time hauling a gross load of over 9i tons behind the drawbar.

At least one other oil tractor has made a 100-mile nonergine-stop run, on one filling of paraffin, but its load was not so great as that hauled by the Marshall 60 ii.p. oil tractor during the test which was recently made under the observation of one of our Editorial representatives. The machine in question is the identical tractor which was designed, and built, by Marshall. Sons and Co., Ltd., of Gainsborough, for competition in the War Department Trials of March last. Like other entrants, Marshall's found that 'the time, between the issuing of the Mechanical Transport Committee's requirements, and the commencement of the trials, was too short to permit of the building, and adequate testing, of an entirely special machine. Other work, in connection with the company's extensive business with its Colonial type of oil tractors for ploughing and other farm requirements, prevented this maker from continuing the tests with its military tractor for some months, hence the long interval which has elapsed between the War Department Trials and the test which was made on the roads around Gainsborough, on Thursday and during the early hours of Friday morning, the 10th and 11th inst. respectively. The test load consisted of a traction wagon bearing a quantity of pig iron, and be

hind this was hauled a van containing plentiful supplies al solid and liquid refreshment for the sustenance of those concerned with the test during the 100 miles of running. The actual imposed loads on the wheels of the tractor and the two trailing vehicles were as follow:—

'['ho engine was started up, with petrol fuel, and at 8.30, on the morning of the 10th inst., the test commenced ; the change over from petrol to paraffin fuel was made within live minutes of the engine's being started. At 8.50, when but just over three miles from the works, an inlet-valve cotter broke, and this caused an engine stop. Unfortunately, the driver's tool and spare kit did not include a spare cotter, an oversight that can only be attributed to hurried preparations for the trial. A messenger was sent back to the works, on foot, and it was not until 9.50 that the engine was again started; at 9.55, the journey was resumed. About 8 miles out from Gainsborough, a stiff climb of about half a mile was encountered, just before reaching the top of the high ground near Caenby Corner, where the Gainshorough-to-Louth road intersects the highway known as Ermine Street, the latter road running directly north and south from Brigg to Lincoln. Caenby Corner-10 miles out from the start—was reached at 11.50, and here drivers were changed, but without stopping the engine; each of the two drivers took turns over 10-mile stages. At .11.18 the train again moved on, arriving at Market Rasen, 20 miles out, at 12.45. At this point, a small quantity of engine oil was added to the crankcase, and various parts of the transmission gear were given a general look round, but no adjustments, alterations, or repairs were carried out at any time during the trial, except the one instance occasioned by the breaking of the valve cotter. At 12.45, the return journey, over the same route, was commenced, and the double journey—Gainsborough-Market Rasen-Gainsborough—was covered twice during the day, these journeys accounting for 80 miles. The last 20 miles was made up of two circuits, of 10 miles each, round Gainsborough, the course taking in Corringham and Blyton.

The time-table for the running, after the first arrival at Market Raaen, was as follows :-1.5 p.m., left Market Ritsen for Gainsborough; 2.40 p.m.. Caenby Corner (30 miles); 2.45 p.m., left Caenhy Corner ; 4.10 p.m., arrived Gainsborough (40 miles); 4.25 p.rn., left Gainsborough for Market Rosen; 6 p.m., arrived Caenby Corner (50 miles); 6.7 p.rn „left Caenby Corner ; 7.50 p.m., arrived for second time at Market Rasen (60 miles); 7.58 p.m., left again for Grainsborough; 9.26 p.m., arrived Caenby Corner (70 miles); 9.53 p.m., left Caenhy Corner ; 11.35 p.m., arrived ilainsborough (80 miles); (Friday morning) 12.5 a.m., start for first 10-mile round ; 2 a.m., start for second 10-mile round; 3.15 a.m., 100 miles completed.

The actual running time was 10 hours and 10 minutes, which gives an average speed of 6.2 m.p.h. Three hours and five minutes were lost on the various stages, for changing drivers, oiling up, and the replacement of the broken valve cotter. After the completion of the 100 miles, the engine still ran for about 15 minutes, during which time it was manoeuvred about the yard, and preparations were being made for " docking " the tractor until a later hour in the morning, when measurements were taken of the total quantities of water, oil, and paraffin consumed. From the time of the engine's being started, after the replacement of the valve cotter, it ran for 18 hours and 10 minutes, maintaining an almost-uniform speed during the whole time, and with a remarkablyclean exhaust. With so much unnecessary waste of time during the intervals between the various stages, coupled with the fact that our representative discovered a serious cause of leakage in one of the paraffin tanks, we cannot place much reliance upon the fuel consumption figures as measured, but we are convinced that the machine is capable of running over 100 miles, on one filling of fuel and water, without any trouble whatever. The roads over which the test was made were in a shocking condition, as they had been covered with snow for many weeks, and had repeatedly been frozen over and then thawed, the result being that the surface was very soft and yielding, and there can be no doubt that the state of the road put up the consumption very much.

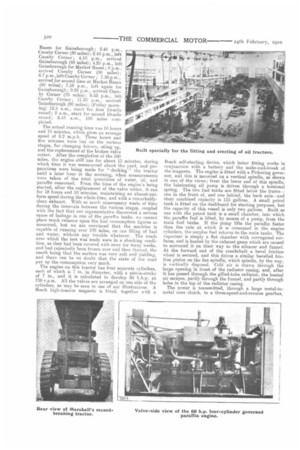

The engine on this tractor has four separate cylinders, each of which is 7 in. in diameter, with a piston-stroke of 7 in., and it is calculated to. develop 60 b.h.p. at 750 r.p.m. All the valves are arranged on one side of the cylinders, as may be seen in one of our illustrations. A Bosch high-tension magneto is fitted, together with a

Bosch self-starting device, which latter fitting works in conjunction with a, battery and the make-and-break of the magneto. The engine is fitted with a Pickering governor, and this is mounted on a vertical spindle, as shown in one of the views; from the lower end of this spindle, the lubricating oil pump is driven through a torsional spring. The two fuel tanks are fitted below the frame— one in the front of, and one behind, the back axle—and their combined capacity is 115 gallons. A small petrol tank is fitted on the dashboard for starting purposes, but the capacity of this vessel is only two gallons. Built as ono with the petrol tank is a small chamber, into which the paraffin fuel is lifted, by means of a pump, from the main fuel tanks. If the pump lifts the paraffin faster than the rate at which it is consumed in the engine cylinders, the surplus fuel returns to the main tanks. Tho vaporizer is simply a flat chamber with corrugated surfaces, and is heated by the exhaust gases which are caused to surround it on their way to the silencer and funnel. At the forward end of the crankshaft a bevel friction wheel is secured, and this drives a similar bevelled friction pinion on the fan spindle, which spindle, by the way, is vertically disposed. Cold air is drawn through the large opening in front of the radiator casing, and, after it has passed through the gilled-tube radiator, the heated air escapes, partly through the funnel, and partly through holes in the top of the radiator casing.

The power is transmitted, through a large metal-tometal cone clutch, to a three-speed-and-reverse gearbox,

the actual speeds being 2, 5 and 7 miles per hour when the engine is running at its normal speed. In the same gearbox, which is of very substantial construction, the bevel-driven differential oountershaft is mounted, and the final drive is by means of two pairs of spur gears, one side of the east-steel teeth being shrouded, as is usual in traction-engine practice. A. winding drum is mounted on the axle, and, when this is brought into operation, the solid axle rotates independently of the road wheels. A point which specially appealed to our representative, in connection with the winding gear of this tractor, is the large diameter of the fair-leads, which are fitted both fore and aft; these are no lase than 11 in. in diameter, and are arranged to operate at any angle. The driving wheels are 5 ft. 6 in. in diameter, with a 12 in. tread, whilst the leaders are 4 ft. in diameter, with a 9 in. tread and a steering strip 41 in. wide. The main frame is made of stout channel-section steel 9 in. deep, with flanges 3 in. wide; it is mounted over the axles on helical springs. Two sets of brakes are provided: one of these, operated by a foot lever, acts directly on to two drums—one on each bevel shaft; the second set of brakes is screw operated, and acts on the internal surfaces of the driving-wheel rims. The differential gear is worth special mention, because of the 43.9.130 with which it may be locked or unlocked by the driver without the necessity for his moving from his position. This locking gear consists of a dog clutch, and the bridle by which it is operated may be spring loaded, when desired, and, when so loaded the two members of the dog clutch are automatically brought into engagement as soon as relative motion takes

place. They may be disconnected by means of a hand lever which is located between the driver and his mate.

This machine is but one of a large number of different types of oil tractors built by this old-established company. The sizes vary from the two-cylinder, 30 h.p. machine, with which one of our representatives made a 24-hour continuous ploughing test, in November, 1907, to the huge Colonial machines, with 70 h.p. engines, which are capable of hauling a plough with from 12 to 15 shares.

Many of our Home farmers refuse to recognize the merits of direct haulage for ploughing and reaping, and possibly the larger sizes of Marshall machines are not quite suitable for English land; it must be remembered, however, that, for countries such as Canada, Argentine and Brazil, where the conditions of farming are so different to our own, and where furrows many mike in length are not uncommon, cable haulage for ploughs is absolutely out of the question. Up to the present time, steam traction engines for direct haulage of ploughs have only been used to a limited extent, because, owing to their great weight, they cannot be taken on to the land when it is soft and in the best condition for ploughing. Consequently, they often have to remain idle. Further, the question of water and fuel is frequently a serious one, and, in those countries where ploughing by mechanical means is necessary or advantageous, coal and wood are often scarce and very expensive, and good feed water for the boiler cannot be obtained. It is for such countries that a Marshall paraffin-engined machine of the type illustrated, or one of the Colonial type, is particularly suitable, and its maker should find an almost unlimited market.