NEW DEPARTURE IN AXLE FIELD

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

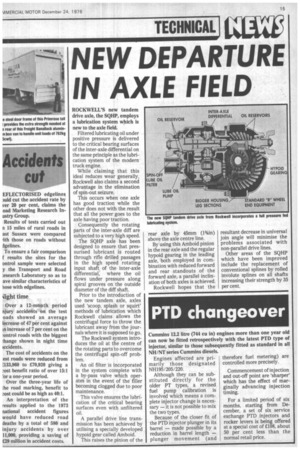

ROCKWELL'S new tandem drive axle, the SQHP, employs a lubrication system which is new to the axle field.

Filtered lubricating oil under positive pressure is delivered to the critical bearing surfaces of the inter-axle differential on the same principle as the lubrication system of the modern truck engine.

While claiming that this ideal reduces wear generally, Rockwell also claims a second advantage in the elimination of spin-out seizure.

This occurs when one axle has good traction while the other does not with the result that all the power goes to the axle having poor traction.

Consequently the rotating parts of the inter-axle diff are subjected to a very high speed.

The SQHP axle has been designed to ensure that pressurised lubricant is routed through rifle drilled passages in the high speed rotating input shaft of the inter-axle differential, where the oil flows under pressure along spiral grooves on the outside diameter of the diff shaft.

Prior to the introduction of the new tandem axle, axles used 'scoop, splash or squirt' methods of lubrication which Rockwell claims allows the centrifugal force to throw the lubricant away from the journals where it is supposed to go.

The Rockwell system introduces the oil at the centre of the rotating parts to overcome the centrifugal spin-off problem.

An oil filter is incorporated in the system complete with a by-pass valve which oper ates in the event of the filler becoming clogged due to poor maintenance.

This valve ensures the lubrication of the critical bearing surfaces even with unfiltered oil.

A parallel drive line transmission has been achieved by utilising a specially developed hypoid gear called Amboid.

This raises the pinion of the rear axle by 45mm (134in) above the axle centre line.

By using this Amboid pinion in the rear axle and the regular hypoid gearing in the leading axle, both employed in combination with reduced forward and rear standouts of the forward axle, a parallel inclination of both axles is achieved.

Rockwell hopes that the resultant decrease in universal join angle will minimise the problems associated with non-parallel drive lines.

Other areas of the SQHP which have been improved include the replacement of conventional splines by rolled involute splines on all shafts increasing their strength by 35 per cent.