A HIGH )0WERED DELIVERY VAN

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

New Thames 5-cwt. Van has a Larger Engine, Hydraulic Brakes and Modern Styling : Ample Power for All Conditions by John F. Moon,

A.M.I.R.T.E.

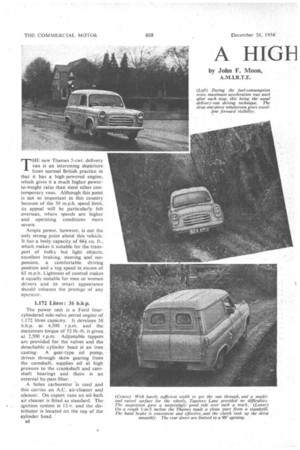

THE new Thames 5-ewt. delivery van is an interesting departure ' from normal British practice in that it has a high-powered engine, which gives it a much higher powerto-weight ratio than most other con-temporary vans. Although this point is not so important in this country because of the 30 m.p.h. speed limit, its appeal will be particularly felt overseas, where speeds are higher and operating 'conditions more severe.

Ample power, however, is not the only strong point about this vehicle. It has a body capacity of 661 cu. ft.. which makes it suitable for the transport of bulky but light objects, excellent braking, steering and suspension, a comfortable driving position and a top speed in excess of 65 m.p.h. Lightness of control makes it equally suitable for men or women drivers and its smart appearance should enhance the prestige of any operator.

1.172 Litres : 36 b.h.p.

The power unit is a Ford fourcylindered side-valve petrol engine of 1.172 litres capacity. it develops 36. b.h.p. at 4,500 r p.m. and the maximum torque of 52 lb.-ft. is given at 2,500 r.p.m. Adjustable tappets are provided for the valves and the detachable cylinder head is an iron casting, A gear-type oil pump, driven through skew gearing from the camshaft, supplies oil at high pressure to the crankshaft and camshaft bearings and there is an external by-pass filter. .

A Solex carburetter is used and this carries an A.C. air-cleaner and silencer. On export vans an oil-bath air cleaner is fitted as standard. The ignition system is 12-v. and the distributor is located on the top of the cylinder head.

58 The single dry plate clutch of 7.38-in, diameter is hydraulically operated. A constant:mesh gearbox gives three forward speeds with synchromesh engagement on top and second gears, and it has a conventional gear lever which is Positioned centrally in the cab floor.

Three-point mounting is employed for the engine and gearbox unit, with rubber units in compression and shear on each side of the front of the engine, and a semi-circular mounting at the rear of the gearbox tail extension, which consists of rubber blocks in shear. This gearbox extension-allows a short propeller shaft to be used, thus reducing the possibility of extensive transmission vibration occurring. The rear axle has three-quarter-floating half-shafts and a spiral-bevel finaldrive which gives a reduction ratio of 4.429 to 1.

Large coil springs, mounted round heavy-duty telescopic dampers, form the independent front suspension, and conventional longitudinal semielliptic springs are used at the rear axle in conjunction with telescopic dampers. Girling hydraulic braking is fitted and the front wheel units have two leading shoes.

There is no separate chassis frame, all-welded integral construction being employed. The front suspension and the power unit are located within a boxed section which consists of the scuttle, front wings and grille pressing, and the rear suspension is carried by a channel section sub-frame, which is supported by the van floor and sides. A sheet-steel pressing is used for the cab floor and the roof panel is deeply swaged to give additional rigidity to the complete assembly.

There are two wide doors to the driving compartment and double doors at the rear of the van, which are carried on self-aligning hinges and have a three-way locking mechanism. Stops prevent these doors from being opened through more than 90°.

When no passenger seat is fitted, the spare wheel is positioned on the cab floor alongside the driving seat. It is stowed in the near side of the body in front of the wheel-arch when two seats are fitted, as was the case with the test van. The seats are adjustable for fore-and-aft movement when the mounting clips are slackened off. A payload of 10 1-cwt. cast-iron weights, located in a wooden tray which was screwed to the body floor, was provided for my test and additional equipment included a fuel test tank and full kit of took. With passenger and driver aboard, the gross Weight of the van totalled 1 ton n cwt. This was If cwt in excess of the recommended gross weight and although not a, practice to be commended when in service, it served during the test as proof of the _adequate power of the engine..

The tests were conducted in the Birmingham area and several consumption rung were made under varying conditions and. payloads. During the two-stops-per-mile tests, the engine was allowed to idle for 15 sec. during each, stop, and maximum acceleration was used at all times.

The road used for -these tests was between Olton and Knowle, a return run being made in each case. This is a, fairly level stretch which did not require the indirect ratios to be used, but it passes through Solihull, where traffic halts were made in each case. Speed was generally kept below 35 m.p.h. and the resulting figures are good for this size of engine.

Light Braking A section of the fuel-consumption route was used for the braking and acceleration trials and although the day was fine, the road surface was still damp enough to cause wheel-lock when making emergency stops. From Nt m.p.h., the average • stopping distance of 14 ft. was obtained without excessive wheel-locking, but from 30 m.p.h., the best results were obtained when full pedal pressure was not used. Braking was light and responsive and had straight-line characteristics from all speeds.

High torque, coupled with a quick gear change, produced good acceleration figures. The readings were taken up to 40 m.p.h. and for the standingstart tests, first and second ratios only were used. The direct-drive-tests from 141 m.p.h. caused the transmission to vibrate slightly during the initial acceleration, but at 14 m.p.h. it smoothed out and the acceleration up to 40 m.p.h. was good.

It was difficult to find a suitable hill in the district on which to try out the pulling power of the van, but Tapsters Lane, in Lapworth, appeared _likely to be suitable. On arrival at the hill, which is sign-posted as

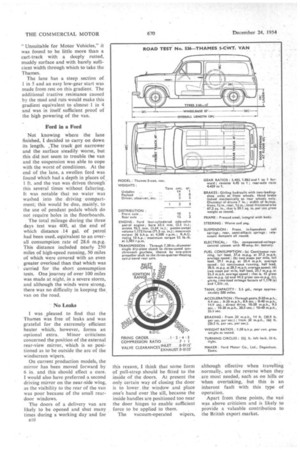

" Unsuitable for Motor Vehicles,'" it was found to be little more than a cart-track with a deeply rutted, muddy surface and with barely sufficient width through which to take the Thames.

The lane has a steep section of 1 in 5 and an easy low-gear start was made from rest on this gradient. The additional tractive resistance caused by the mud and ruts would make this gradient equivalent to almost 1 in 4 and was in itself sufficient proof of the high powering of the van.

Ford in a Ford

Not knowing where the lane finished, I decided to carry on down its length. ,The track got narrower and the surface steadily worse, but this did not seem to trouble the van and the suspension was able to cope with the worst of conditions. At the end of the lane, a swollen ford was found which had a depth in places of 1 ft. and the van was driven through this several times without faltering. It was notable that no water was washed into the driving compartment; this would be due, mainly, to the use of pendant pedals which do not require holes in the floorboards.

The total mileage during the three days test was 400, at the end of which distance .14 gal. of petrol had been used, equivalent to an overall consumption rate of 28.6 m.p.g. This distance included nearly 250 miles of high-speed running, 50 miles of which were covered with an even greater overload than that which was carried for the short consumption tests. One journey of over 100 miles was made at night, in a severe storm, and although the winds were strong, there was no difficulty in keeping the van on the road.

No Leaks I was pleased to find that the Thames was free of leaks and was grateful for the extremely efficient heater which, however, forms an optional extra. Minor criticisms concerned the position of the external rear-view mirror, which is so positioned as to be outside the arc of the windscreen wipers.

On current production models, the mirror has been moved forward by 6 in. and this should effect a cure. I would also have preferred a second driving mirror on the near-side wing, as the visibility to the rear of the van was poor because of the small reardoor windows.

The doors of a delivery van are likely to be opened and shut many times during a working day and for this reason, I think that some form of pull-strap should be fitted to the inside of the doors. At present the only Certain way of closing the door is to lower, the window and place one's hand over The sill, because the inside handles are positioned too near the door hinges to enable sufficient force to be applied to them.

The vacuum-operated wipers, although effective when travelling normally, are the reverse when they are most needed, such as on hills or when overtaking, but this is an inherent fault with this type of operation.

Apart from these points, the van was above criticism and is likely to provide a valuable contribution to the British export market.