WHY WHEELS WOBBLE

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockington, THE steering assembly of a vehicle has a natural flap frequency, and when a low-speed wobble is experienced it can be attributed to an exciting force with a similar frequency. This force may be small, but if undamped, it can increase the magnitude of the oscillations until they become uncon trollable. Eventually, the chassis itselfis affected, and the wobble

builds up into a front-end shimmy. The natural flap frequency of a commercial vehicle fitted with heavy tyres is low, and the corresponding road speed is seldom in excess of 15-20 m.p.h.

The exciting force is a function of road impact on the tyres, and oscillations occur because the forces on both wheels vary rhythmically within the resonant range of shock intervals. Such a condition may exist if the wheels be misaligned and each tyre is attempting to return to the straight-ahead position. In the absence of damping, a short series of .shocks can then produce violent oscillations, which will continue until the vehicle speed is altered or the bump pattern of the road changes.

Excessive toe-in or toe-out, on a straight and flat road, produces equal and opposite self-aligning forces,

which act on the tyre treads. In many ways, the effect of toe-out is generally beneficial in preVenting wobble, but toe-in can be a dangerous factor, particularly if combined with a large castor angle.

A Matter of Degree When, for example, the castor is 6 degrees or more, a toe-in of in.

to in. may lead to wobble -under critical conditions, whilst a toe-in of

in. to I in. may not give trouble, except in the form of tyre squeal and rapid wear, if the axle has a castor angle of 1-2 degrees. Whereas castor increases the self-aligning action of both toe-in and toe-out, the effect of toe-out is opposed to rolling resistance, and in the usual type of steering layout, wheel-wobble tendencies are generally counteracted by increasing the setting.

Flexingof the tie-rod is also important. When the rod is located at

tern, excessive toe-out maintains the rod in tension and whip is prevented. Toe-in compresses the rod, and bending is more likely to occur. This may cause bending at the critical speed and partly explain the results described.

It is necessary to differentiate between self-righting torque as applied to a vehicle travelling on a straight, flat road, and to a vehicle which is being steered round a bend. On a bend, the front axle castor and the .precession torque of the tyres tend to turn both wheels back to the straight in the same direction.

The forces acting on the treads are not opposed as they are when there is no side thrust on the vehicle. Wobble will not, therefore, occur on a corner except under most abnormal conditions. Reduced castor and excessive toe-out both increase the tendency to 'wander when travelling straight, and the driver must continually manipulate the steering to keep on his course.

Contrary to popular opinion, unbalanced wheel assemblies cannot cause low-speed wobble, but they often result in medium-speed "niggle" and high-speed wobble. Dynamic unbalance may produce a small side-to-side oscillation at 3540 mph., and static unbalance, a more severe vertical vibration at a higher speed.

High-speed wobble is frequently caused by gyroscopic kick, the wheels of a beam-axle vehicle being thereby deflected in the sarne. direction when -the axle is tilted. . Whilst the Wheelcamber of most independent suspension systems changes with bump deflection, kick phasing is virtually impossible, and much softer springs can be used without fear of oscillation build-up.

Worn king-pinsand steering parts are not, as a rule, a direct cause of low-speed wobble. If the joints be excessively worn, it is, however, difficult to make the correct allowance when adjusting the steering geometry, and accurate setting in the garage is no guarantee of correct alignment on

the road. • Pronounced wear is more nicely to be a contributory cause of highspeed wobble, particularly when the wheels are unbalanced. When the wheels can flap independently of each other, local , oscillations will occur at a higher rate than the combined flap frequency.

An unusual example of low-speed wobble serves to illustrate how complex related problems can be when a vehicle is in the prototype stage. Variation of geometric settings failed to cure wheel wobble of a vehicle under test, and eventually it was found that a rigidly attached radiator was vibrating at the natural flap frequency in resotiance with the steering system. Fitting flexible radiator mountings cured the trouble.

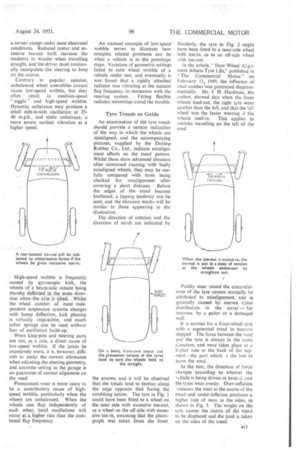

An examination of tht tyre treads should provide a certain indication of the way in which the wheels are misaligned, and the accompanying pictures, supplied by the Dunlop Rubber Co., Ltd., indicate misalignment effects on the tread pattern. Whilst these show advanced abrasion after continued running with badly misaligned wheels, they may be usefully compared with tyres being checked for misalignment after covering a short distance. Before the edges of the tread become feathered, a lipping tendency can be seen, and the abrasion marks will be similar to those appearing in the illustration.

The direction of rotation and the direction of scrub are indicated by the arrows, and it will be observed that the treads tend to feather along the edge opposite that facing the scrubbing action. The tyre in Fig. 1 could have been fitted to a wheel on the near side with excessive toe-out, or a wheel on the off side with excessive toe-in, assuming that the photograph was taken from the front Similarly, the tyre in Fig. 2 might have been fitted to a near-side wheel with toe-in, or to an off-side wheel with toe-out.

In the article, " How Wheel Alignment Affects Tyre Life," published in " The Commercial Motor" on February I I; 1949, the influence of road camber was portrayed diagrammatically Mr. J H. Hardman, the author, showed that when the front wheels toed-out, the right tyre wore quicker than the left, and that the left wheel was the faster wearing if the wheels toed-in. This applies to vehicles travelling on the left of the road.

Patchy wear round the circumference of the tyre cannot normally be attributed to Misalignment, _add is generally caused by Uneven Miss distribution in the cover — for instance, by a gaiter or a damaged wall.

It is normal for a front-wheel tyre with a segmented tread to become stepped The force between the road and the tyre is always in the same Cirection, and wear takes place at a higher rate at the back of the segment—the part which s the last to leave the road.

At the rear, the direction of force changes according to whether the ‘rhicle is being driven or brakeJ, and the tyres wear evenly. Over-inflation Increases the wear at the centre of the tread and under-inflation produces a higher rate of weal at the sides, as shown in Fig. 3. The weight on the tyre causes the centre of the tread to be displaced and the, load is taken on the sides of the tread.