Fuel-pumping System That Will Not Air Lock

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé , of Patent _Specifications That Have Recently Been Published

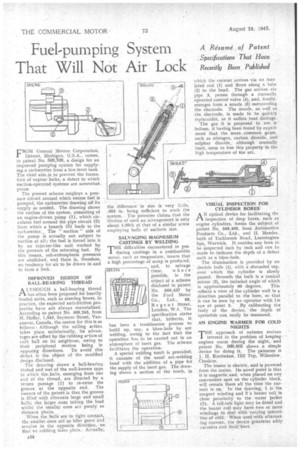

Frt•OM General Motors Corporation, D,etroit, Michigan, U.S.A., comes, in patent No. 509,769, a design for an improved pumping system for supplying a carburetter from a low-level tank The chief aim.is to prevent the formation of vapour locks, a defect to which suction-operated systems are somewhat. prone.

The present scheme employs a pressure circuit around which excess fuel is pumped, the carburetter drawing off its supply as needed. The drawing shows the outline of the system, consisting of an engine-driven pump (1), which circulates fuel around the pipe circuit (2) from which a branch (3) leads to the carburetter._ The " suction " side of the pump is actually not subject to suction at all; the fuel is forced into it by an injector-like unit worked by the pressure of the returning fuel. By this means, sub-atmospheric pressures are abolished, and there is, therefore, no tendency for air to be drawn in and to form a lock.

IMPROVED DESIGN OF BALL-BEARING THREAD

A LTHOUGH a ball-bearing thread t-1 has often been 'proposed for heavily loaded units, such as steering boxes, in practice, the expected anti-friction properties have not always materialized. According to patent No. 569,245, from H. Hoffar, 1,343, Seymour Street, Vancouver, Canada, the reaSon for this is as follows:, Although the rolling action takes place satisfactorily, its advantages are offset by the rubbing action of each ball on its neighbour, owing to their peripheral motion beine. in opposing directions. To avoid this defect is the object of -the modified design disclosed.

The drawing shows a ball-bearing thread and nut of the well-known type in which theeballs, emerging from one end of the thread, are directed by a return passage (1) to re-enter the groove at the opposite end. The essence of the patent is that the groove is filled with alternate large and small balls; .the larger ,ones, taking the load whilst the smaller ones act purely as distance pieces.

When the.ballsare in tight contact, the smaller ones act as idler gears andrevolve in the opposite direction, so. that no rubbing takes place. Actually, the difference in size is very lade, .005 in. being sufficient to work the system. The patentee claims. that the friction of such an arrangement is only about 1-20th of that of a similar screw employing balls of uniform size.

SALVAGING MAGNESIUM CASTINGS BY WELDING

THE difficulties encountered in proclueing castings in a combustible metal, such as magnesium, means that a high percentage of scrap is produced, and, to salvage

these, where possible, is the object of a scheme disclosed in patent No. 569,437 by the Ford Motor Co., Ltd., 88, Regent Street, London, W.I. The specification states that, hitherto, it has been a troublesome process to build up, say, a blow-hole by arc welding, owing to the fact that the operation has to be carried out in an atmosphere of inert gas. The scheme facilitates the operation.

A special welding torch is provided; it consists of the usual arc-welding head with the addition of a pipe for the supply of the inert gas. The drawing shows a section of the torch, in

569,2*5

which the current arrives via an insu lated rod (1) and flows along a tube (2) to the head. The gas arrives via pipe 3, passes through a manually operated control valve (4), and, finally, emerges from a nozzle (5) surrounding the electrode. The nozzle, as well as the electrode, is made to be quickly replaceable, as it suffers heat damage.

The gas it is proposed to use is helium, it having been found by experiment that the more -.common gases, such as nitrogen, carbon dioxide, and sulphur dioxide,. although normally inert, seem to lose this property in the high temperature of the arc.

VISUAL INSPECTION FOR CYLINDER BORES ANoptical device for facilitating the inspection of deep bores, such as engine cylinders, forms the subject oi patent No 569,400, from Automotive Products Co., %Ltd., and H. Mandel, both of Tachbrook Road, Leamington Spa, Warwick. It enables any bore to be -inspected inch by inch and can he made to indicate the depth of a defect such as a blow-hole.

The illumination is provided by an electric bulb (1), with a shrouded top, over avhich the cylinder is slowly passed. Beneath the bulb is a conical mirror (2), the included angle of which is approximately 90 degrees. This reflects a view of the cylinder wall in a direction parallel to the bore, so that it can he seen by an operator with his eye at point 3. By calibrating the body of the device, • the depth of operation can easily be measured.

AN ENGINE WARMER FOR COLD NIGHTS

THE approach of autumn revives interest in the problem of keeping engines warm during the night, and patent No. 560,805 shows a simple device for doing it. The patentee is J. H. Runbaken, Hill Top, Wilmslow, Cheshire.

The heater is electric, and is powered from the mains. Its novel point is that it is magnetic.and, when placed on any .convenient spot on the cylinder block, will remain there all the time the current is on. In the drawing, 1 is'the magnet winding and 2 a heater coil in close proximity to the water jacket (3). A tell-tale light may be fitted and the heater coil may have two or more windings to deal with varying intensities .a cOld. ' When used with alternating current, the device generates eddy currents and locarheat.