SCAMMELL HANDYMAN FORWARD-CONTROL ARTICULATED OUTFIT

Page 178

Page 179

If you've noticed an error in this article please click here to report it so we can fix it.

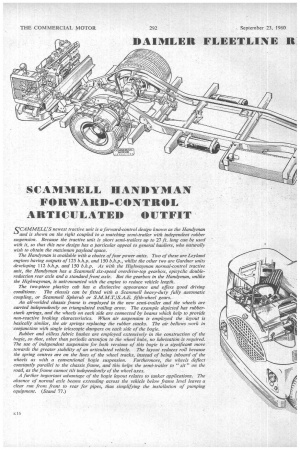

SCAMMELL'S newest tractive unit is a forward-control design known as the Handyman and is shown on the right coupled to a matching semi-trailer with independent rubber suspension. Because the tractive unit is short semi-trailers up to 27 ft. long can be used with it, so that this new design has a particular appeal to general hauliers, who naturally wish to obtain the maximum payload space.

The Handyman is available with a choice of four power units. Two of these are Leyland engines having outputs of 125 b.h.p. and 150 b.h.p., whilst the other two are Gardner units developing 112 b.h.p. and 150 b.h.p. As with the Highwayman normal-control tractive unit, the Handyman has a Scammell six-speed overdrive-top gearbox, epicyclic doublereduction rear axle and a standard front axle. But the gearbox in the Handyman, unlike the Highwayman, is unit-mounted with the engine to reduce vehicle length.

The two-piece plastics cab has a distinctive appearance and offers good driving conditions. The chassis can be fitted with a Scammell heavy-duty fully automatic coupling, or Scammell Spherub or S.M.M.T.1 S.A.E. fifth-wheel gears.

An all-welded chassis frame is employed in the new semi-trailer and the wheels are carried independently on triangulated trailing arms. The example depicted has rubberstack springs, and the wheels on each side are connected by beams which help to provide non-reactive braking characteristics. When air suspension is employed the layout is basically similar, the air springs replacing the rubber stacks. The air bellows work in conjunction with single telescopic dampers on each side of the bogie.

Rubber and oilless fabric bushes are employed extensively in the construction of the bogie, so that, other than periodic attention to the wheel hubs, no lubrication is required. The use of independent suspension for both versions of this bogie is a significanr move towards the greater ,stability of an articulated vehicle. The layout reduces roll because the spring centres are on the lines of the wheel tracks, instead of being inboard of the wheels as with a conventional bogie suspension. Furthermore, the wheels deflect constantly parallel to the chassis frame, and this helps the semi-trailer to " sit " on the road, as the frame cannot tilt independently of the wheel axes.

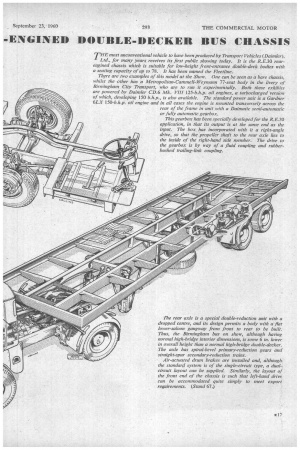

A further important advantage of the bogie layout relates to tanker applications. The absence of normal axle beams extending across the vehicle below frame level leaves a clear run from front to rear for pipes, thus simplifying the installation of pumping equipment. (Stand 77.) THE most unconventional vehicle to have been produced by Transport Vehicles (Daimler), Ltd., for many years receives its first public showing today. It is the R.E.30 rearengined chassis which is suitable for low-height front-entrance double-deck bodies with a seating capacity of up to 78. It has been named the Fleet/inc.

There are two examples of this model at the Show. One can be seen as a bare chassis, whilst the other has a Metropolitan-Cammell-Weymann 77-seat body in the livery of Birmingham City Transport, who are to run it experimentally. Both these exhibits are powered by Daimler CD.6 Mk. VIII 125-b up, oil engines, a turbocharged version of which, developing 150 b.h.p., is also available. The standard power unit is a Gardner 6LX 150-b.h.p. oil engine and in all cases the engine is mounted transversely across the rear of the frame in unit with a Daimatic semi-automatic or fully automatic gearbox.

This gearbox has been specially developed for the R.E.30 application, in that its output is at the same end as the input. The box has incorporated with it a right-angle drive, so that the propeller shaft to the rear axle lies to the inside of the right-hand side member. The drive to the gearbox is by way of a fluid coupling and rubberbushed trailing-link coupling.