PROFILE D BARDSLEI & SON FACTFILE D Bardsley & Son.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

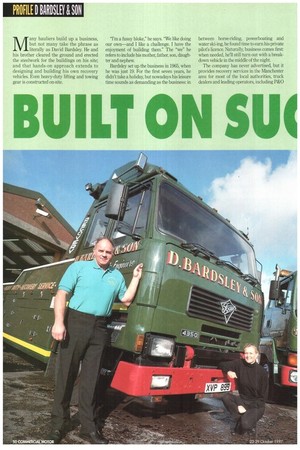

BASED: Atherton, Manchester. FOUNDED: 1965. CONTACT: David Bardsley. FLEET: Four heavy and two light recovery vehicles. SPECIALITY: Accident and breakdown recovery, vehicle and trailer servicing and maintenance. TURNOVER: E670,000. Many hauliers build up a business, but not many take the phrase as literally as David Bardsley. He and his brother cleared the ground and erected the steelwork for the buildings on his site; and that hands-on approach extends to designing and building his own recovery vehicles. Even heavy-duty lifting and towing gear is constructed on-site.

"I'm a fussy bloke," he says. "We like doing our own—and I like a challenge. I have the enjoyment of building them." The "we" he refers to include his mother, father, son, daughter and nephew.

Bardsley set up the business in 1965, when he was just 19. For the first seven years, he didn't take a holiday, but nowadays his leisure time sounds as demanding as the business: in between horse-riding, powerboating and water ski-ing, he found time to earn his private pilot's licence. Naturally, business comes first: when needed, he'll still turn out with a breakdown vehicle in the middle of the night.

The company has never advertised, but it provides recovery services in the Manchester area for most of the local authorities, truck dealers and leading operators, including P&O

Ferrymasters, Tuffnells, Ryder and MAN Manchester.

Some of the work comes from a Liverpool customer which, like so many more local users, relies on the company for its expertise and reliability "All our lads are technicians," says Bardsley. "There are no labourer-drivers."

These days there's a growing demand for continental recovery work to the UK, fuelled by sharp practices from some European garages and huge repair bills, In a recent case, the French reported a broken valve and the need for a replacement engine, at an estimated cost of £9,000. After the truck was towed home, it was found to have two broken rocker bolts.

Bardsley also handles recovery work for police forces—one job involved picking up a light aircraft that had landed on the M62. The police wanted the motorway reopened as quickly as possible, which meant it was not possible to take off the plane's wings, which were still full of fuel.

The plane was transported sideways, but still had an overall width of 27ft. Before the load could negotiate the slip road off the M62, the fire brigade had to go ahead and turn the road signs through 90° to make room.

Another tricky operation involved recovery of a laden fuel tanker which had been negotiating a narrow hill alongside some cottages. One side of the roadway gave way, leaving the tanker leaning at a steep angle, inches away from the upper floor of the cottages. Another recovery operator had taken on the job, but cried off when he saw the problem. Bardsley's team used airbags and built up a new roadway of wooden sleepers under the tanker before winching it back the way it had gone in.

Broken gearbox

A recent and apparently simple job—also passed on by another operator—involved towing an eight-Iegger with a broken gearbox to Edinburgh and guaranteeing an arrival time of 18:00hrs or earlier. Eightwheelers are not the most popular vehicles for towing because of the cramped nature of the underside and lack of access. It was a bitterly cold day, with the temperature at times falling well below zero, causing problems of fuel freezing on many vehicles.

Having taken on the job, there was a temporary halt when Bardsley found that the vehicle in question, a BBC TV mobile studio, was valued at Dm! Suitable insurance was hurriedly arranged, the job was completed successfully and the vehicle was duly deposited in the shadow of Edinburgh Castle before 18:00hrs on 31 December, ready for the traditional Scottish Hogrnanay/New Year's show. Bardsley originally decided to build his own recovery vehicles because he "didn't rate very highly" a lot of the equipment available. An early vehicle was an E-reg Foden heavy haulage tractor that had been a hire-purchase repossession. The chassis was extended and a body; jib and ancillary equipment constructed. You need at least a 10-year economic life for a recovery vehicle, Bardsley reckons, adding that the bodywork on most commercially available models is not durable enough.

The ones he builds have bodywork 3mm thick. Veteran of the current fleet is a Leyland Daf four-wheeler converted 10 years ago. It has never been repainted, -but still looks fine with no sign of rust. The Leyland Daf has an underlifting capability and all the other features Bardsley regards as essential. Like the rest of the recovery vehicles in his fleet, it's plated and tested, although this is not a legal requirement. Also like the fleet, it runs on Bridgestone tyres on the front with Michelins on the rear.

These days recovery work involves more than simple recovery or towing: the fleet includes a curtainsided trailer to carry the load from a disabled vehicle.

Conventional tractor

Work is also in progress on converting a conventional tractor by repositioning the suzies and other equipment so that it can pull close-coupled (or what were close-coupled) fridge trailers without damage.

Despite Bards( s y ley 's enthusiasm for

recovery work, some two-thirds of the business's turnover is generated by servicing and maintenance work; once again, much of this is for well known fleets, including major waste-disposal contractor& It sounds rosy enough. but Bardsley is none too optimistic about the future. The cut-price deals now so readily available for new trucks have encouraged a growing number of dealers to extend their servicing and repair work in a bid to squeeze out the independents. "Yet we spend £26,000 a month buying parts for our contract maintenance work from these dealers," he says.

Bardsley is particularly concerned by some manufacturers' efforts to restrict parts availability. He also points out the way big companies are suddenly bought or sold: "You can do nothing wrong, yet lose out when this happens, and what was your regular work goes elsewhere. We don't say we're the best," he concludes, "but we do say we are interested in what we do. And on recovery work, we've never had a complaint about damage."

Li by John Aldridge