One of the best examples of its installation can be

Page 106

Page 107

Page 109

Page 110

Page 111

If you've noticed an error in this article please click here to report it so we can fix it.

seen in the new 301 tractive unit which Seddon Atkinson claims was in fact designed around the engine in the first place instead of being merely just another engine option.

As installed in the 301, the Cummins develops 180kW (241bhp) and drives through a twin-plate Lipe Rollway clutch with ceramic linings to a Spicer SST 8010 gearbox. The Spicer is a 10-speed splitter design and is fitted with the optional alu minium casing in line with Seddon Atkinson policy of g for a very low kerb weight ft new 38-tonner.

All Seddon Atkinson tra units now use the lnternati RA-57, which is assemble Oldham from the casings come from Raba in Hun! the driving head whic machined and assemble( Oldham, and the drive sl which come from the USA.

Scania is another man turer to have abandoned it naturally aspirated engine. the DS8-06 turbocharged er replacing the naturally aspir DN8 used in some of the 16 ners, the whole Scania rang the UK market is now tt charged.

The DS8-06 is at BirminG in a G82M 16-ton haulage sis. In its new rating the 7.E (476cuin) in-line six-cylinde gine develops 140kW (18E with a maximum torqui 665Nm (490Ibft). As usual Scania, a synchromesh ges of in-house manufacture is with five speeds in conjun with a Scania single redu axle.

The turbocharged and ch. cooled DSi8 engine is an variant of the 7.8-litre engin, is an interesting design ir sense that it features an E water charge-cooling syster This system is less eff than the air-to-air type al usually only employed 131 proprietary engine manufr ers who prefer to build charge-cooler into the basi gine package rather than b dent upon a chassisnted cooler.

spite of the fact that Scania )usly has total control over vn chassis, the Swedish en3rs have opted for an air-tor system built in to the rear on of the inlet manifold. In DSI8 form, the engine de velops 172kW (231bhp) coupled with a maximum torque of 825Nm (6071bft).

The DSi8 installation can be seen in three Scania vehicles, including the new eight-wheeler.

The latter is Scania's first serious attempt at the eightwheeler market although prototypes have been running in Sweden (notably with BP Svenska) for some time now. The Scania 10-speed range change gearbox is fitted. At the top end of the Scania range is the R142, plated for 52 tonnes gcw. This is powered by the DS14 14.2-litre (866cuin) V8 engine which is turbocharged to produce 290kW (388bhp) with a maximum torque of 1,580Nm (1,165Ibft) — fractionally less than the lveco V8 turbocharged unit.

Except for off-road vehicles, Scania favours single reduction axles with the one fitted to the R142 tractive unit having a 3.88 to one ratio.

Having disposed of its interest in Iveco, the Deutz engine side of the KHD empire is attending the Motor Show for the first time as an entirely independent supplier. Indeed, according to Deutz, "withdrawal from truck manufacture has removed an inhibiting factor on sales and cus= tomers have already responded favourably."

The Ford decision to include the F6L 413F engine as an option in certain Cargo models was a spectacular success for Deutz. This is a V6 configuration with a capacity of 9.6 litres (586cuin) and, as installed in Cargo, it develops 1 52kW (204bhp) at 2,500rpm. Like all Deutz engines it is, of course, air-cooled.

An interesting newcomer on the Deutz stand is the turbocharged and charge-cooled BF6L continued on page 201 FRC which has the same acity as the engine just desJed but here it is an in-line t. Power output is 200kW )bhp) at 2,300rpm with a Kimum torque of 1,330Nm llbft) at 1,650rpm.

his engine in its naturally asited form is already in wideead use through Europe ording to Deutz. A major user the Yugoslav heavy lorry nufacturer TAM. In the UK, ; turbocharged version is nd in Coles road cranes and a ✓ Terex dumper. The turborged and charge-cooled en

e has been the subject of a relopment programme at JtZ with the result that it has

been approved for lorry :allation at up to 38 tonnes ss.

nprovements to the Bathe-built 98-Series engine have n progressively introduced Leyland over the last two irs, with the final modificaIs coming on stream with the nch of the new Boxer replacent described elsewhere in ; issue.

addition to the Freighter litions, the modified engines also be fitted to the Terrier Ithe Boxer run-out models.

he most noticeable changes he 98-Series engine include introduction of controlled exision three ring pistons and a ✓ helical inlet port designed eliminate the need for a sked inlet valve.

he new port design means It valve rotation can be mitted which Leyland claims improve local thermal condiis as well as extending valve I seat life.

,II turbocharged models in new Freighter range are od with the 56-36 six-speed chromesh gearbox from ZF. Is is the gearbox which sed a political stir within the land workforce when it was lounced that the unit would assembled at Albion. Curcy fluctuation has made this ;conomic so the gearbox is v imported complete.

he ZF box is offered in two Ins with either a direct or rdrive top gear ratio. The ;ct top box has a bottom gear D of 9.97 compared with the I of the overdrive (0.73) veri.

he other gearbox for the ighter is the five-speed ner T5-300, a synchromesh ign which is again available verdrive or direct top.

he new Cruiser 16.23, which ; featured in last week's CM, -ated at 35 tonnes and is vered by the Leyland TL11B me. Compared with the TL

which continues for the Cruiser 16.21, the B-rated version has a seven-per-cent increase in power and a 16-percent increase in maximum torque with the actual performance figures being 167kW (224bhp) at 2,100rpm and 956Nm (7031bft) at 1,30Orpm.

Changes introduced for the TL 11B will also lead across to the TL11A and include increasing the section depth of the top deck of the cylinder block to improve block stiffness and gasket sealing capacity.

Other improvements include a revised Mahle piston, a new crankshaft rear oil seal and a new timing case which enables the power steering pump to be repositioned allowing a frontmounted alternator to be specified.

The TL11B is matched to the Fuller RTX 7609 nine-speed gearbox which is a Multimesh design featuring a conventional H-pattern gear change.

A lot has happened at L. Gardner and Sons since the 1980 Motor Show. The science of tur bocharging has been applied throughout the Gardner range which now covers the 182 to 225kW (177 to 300bhp) category for automotive use.

The NEC provides coach operators with their first chance to see the new 6HLXCT which, as its type number suggests, is a horizontal derivative of the six cylinder vertical 6LXCT intro duced 18 months ago. Rated at 172kW (230bhp), at 1,900rpm, the new engine is intended primarily for coach application with a derated version at 132kW (177bhp) being available for buses.

As usual with Gardner engines, the company claims ex cellent fuel consumption coupled with extremely light weight. The lightness is due to its unique construction, which uses a separate block and crankcase, with the latter being cast in aluminium alloy. Gardner is claiming an sfc of 193g/kWh (0.318Ib/bhph) at 1,400rpm for the 6HLXCT and a weight of 858kg (1,8921b).

Externally, the 6HLXCT is similar to the 6HLXB naturally aspirated unit with the only major obvious differences being a rear-mounted turbocharger, revised inlet and exhaust manifolds and a new alternator drive belt assembly. The alternator drive is now no longer situated in the conventional Gardner position but is mounted on a common bracket with the air compressor, both being driven by Poly-V belts.

As well as having the horizontal engine, Gardner is also featuring the vertical 6LXCT and 8LXCT engines on its stand — a complete reversal of the 1980 naturally aspirated picture. Gardner engines can also be seen in manufacturers' chassis, on the ERF, Seddon Atkinson, Sandbach Engineering, Dennis and MCW Stands.

In these days of high torque — low-revving engines, it is perhaps worth remembering that Renault (née Berliet) was one of the first manufacturers to investigate this particular line of thought. The latest development is the MIDR 06.35.40 engine in the new R310 tractive unit, which is intended to become the flagship of the Renault range in the UK when it becomes available in mid-1983.

Although, like lveco, Renault has abandoned its long serving, individual marque names, this has escaped the foundry at Lyons as the cylinder blocks still have Berl jet cast on the side. Renault engine type numbers are complicated but logical.

The new Renault B9 gearbox is fitted to the R310. This is a heavy-duty nine-speed rangechange unit which is manufactured at Renault's new automated factory at Boutheon near St Etienne. The flexible manufacturing system (FMS) used for the machinery of the casings for this synchromesh gearbox was featured in the CM issue of October 9. The G260 is another new tractive unit with a Renault badge on the front being aimed at the lightweight trunking/distribution market. It is powered by the MIDR 06.20.45, a 9.6-litre (586cuin) turbocharged and charge-cooled engine which again features the Renault direct injection system. It is rated at 192kW (260bhp) at 2,200rpm with a maximum torque output of 1,040 Nm (7661bft) at 1,40Orpm.

The new Renault B9 gearbox is again to be found on the G260.

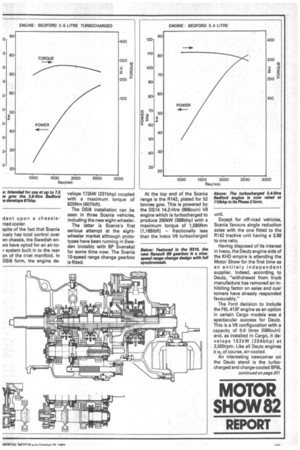

Following the trend of the last few years, Bedford is now 100 per cent turbocharged for its lorry and bus range. The latest developments in the Bedford engine range are the Phase II variants of the 3.6-litre (220cuin) four-cylinder and 5.4-litre (330cuin) six-cylinder Red Series turbocharged engines.

The former is rated at 65kW (87bhp), at 2,600rpm, and replaces the existing 54 kW (726bhp) turbocharged unit in the lighter TK and TL models. The new engine offers a 21 per cent increase in output over the turbocharged unit it replaces and a 34 per cent increase overthe equivalent naturally aspirated engine which is now only available for non-European export markets.

The latest 3.6-litre engine has a maximum torque of 272Nm (198Ibft) at 1,600rpm and is now standard for TK and TL in the 51/2 to 71/2-tonne sector.

The six-cylinder Red Series engine is now available in 100kW (135bhp) form but in this case it does not replace the Phase I 80kW (107bhp) version which is retained as a lower power option. The Phase II engine develops 407Nm (299Ibft) torque at 1,600rpm in its latest uprated form.

In order to exploit the additional engine performance in TK/TL and the VAS and SB bus chassis, Bedford has made some driveline improvements which apply regardless of which engine is specified.

The rear axles for the 51/2 to 81/2-tonne models now feature a larger crown wheel and pinion manufactured from casehardened steel. The current 11tonne heavy duty Bedford spiral bevel axle used on the 15 and 16-tonne chassis has been changed to a hypoid design and will also replace proprietary units on TM chassis with Bedford engines.

Additional axle ratios on the medium duty have enabled Bedford to replace the overdrive gearboxes with direct top units — either four-or five-speed — which the company claims has been done without sacrificing top gear performance. Direct drive transmissions are a feature of the latest TM range announced earlier in the year.

Bedford is one of the manufacturers who will be fitting the new Cummins LT10 engine with the TM, having such an option from January 1983, As installed, the engine develops 1 8 0 kW (240bhp) and initially will be available in the TM 3800 tractive unit (in two wheelbases) and the TM 1700 rigid again in two wheelbases.

The gearbox chosen to match up with the 10-litre is the Fuller RTO 11609, which in contrast to Bedford's thinking in the middleweight category has an overdrive (0.74) top gear ratio. Since its introduction in 1975, the Fiat 17.2-litre (1,047cuin) has gradually moved up the power scale. Never short of horsepower, the engine is now turbocharged to develop 280kW (380bhp) DIN at 1,900rpm for fitment in the latest 190.38 tractive unit from lveco. In its continuing battle with Scania for the torquiest truck, the Fiat now produces 1,650Nm (1,21 7Ibft), which lveco claims is more than any other European production road vehicle.

Another first on the Iveco Stand is the 165.24 tractive unit, which is having its UK premiere. Aimed at the F7, Scania 82 and Cruiser category, the 165.24 is powered by the water-cooled 8220.22 Fiat engine of 9.6-litres (5 86cuin) capacity driving through a 380mm (15in) single dry plate clutch to a nine-speed Fuller RTO 6609 Multimesh gearbox. The clutch has automatic adjustment and air assisted operation.

The maximum output from the Fiat engine, which is a turbocharged derivative of the power unit, is 177kW (240bhp) DIN at 2,300rpm, while the maximum torque figure is 854Nm (630Ibft) at 1,300rpm.

The Fuller box has an overdrive top gear, which in conjunction with the 5.73 ratio in the double reduction rear axle gives a maximum governed road speed of 107km/h (65mph) and a rolling start gradeability of 1 in 4.7 or 21.2 per cent.

For operators requiring higher power outputs in the 71/2-tonne category, lveco has introduced the 8060.04 six-cylinder engine which is a naturally aspirated Fiat design of 5.5 litres (336cuin) capacity. This is fitted to the new 97.13.1 lveco 71/2 tonner which will be sold alongside the existing four-cylinder 79.10.1 model.

The 8060.04 follows conventional Fiat design practice with toroidal combustion chambers in the piston crowns, seven bearing crankshaft with induction hardened journals and a cast iron block with dry liners.

It develops 92kW (123bhp) at the comparatively high speed for a direct injection engine of 3,200rpm with a maximum torque of 3 43Nm (2 53Ibft) at 1,800rpm. This makes the 97.13.1 from Iveco one of the most powerful vehicles available in the 71/2-tonne category.

Drive from the engine is taken through a 305mm (12in) diameter hydraulically operated single dry plate clutch to a five-speed Fiat gearbox with synchromesh on the upper four ratios. Top gear is direct which gives the vehicle a top speed of 103km/h (64mph) and a rolling gradeability of 1 in 25 or 45 per cent with the standard axle ratio of 4.5.

One of the most interesting exhibits from a drive-line point of view is the new off-road normal control 4x4 chassis from Iveco. Designated the 192M16AK, the new model replaces the 170D15AK, with the major differences being the higher powered diesel engine and six-speed synchromesh gearbox.

The engine is the Deutz F6L413F air-cooled V6 with a maximum output of 141kW (192bhp) at 2,500rpm and a maximum torque of 618Nm (458Ibft) between 1,400 and 1,600rpm. The engine swept volume is 9.6-litres (586cuin).

Drive from the Deutz is through a 381mm (15in) single dry plate clutch with automatic adjustment to a ZF S6-65 gearbox with a separate two-speed transfer box splitting the drive to the front and rear axles.

The transfer box has ratios of 1.032 and 1.783 for on and offroad use respectively and incorporates a pneumatically lockable, planetary differential unit. Both front and rear axles have spiral level gearing — the rear has a cross axle diff lock and secondary reduction in the hubs.

The axle ratio, front and rear, is 5.73 to 1 which gives a 80km/h (50mph) top speed and a gradeability of 1 in 2.6 or 39 per cent in the high range. With the offroad ratio, the top speed is 47km/h (29mph) and the grad bility 1 in 1.2 or 82 per cent.

Although Perkins has nounced that production of new Q14 family of engines not start until 1985, the Peter rough company is using Motor Show to give the Bri' operator his first chance to one of the new engines. The ( family will include four, five six-cylinder engines with top-of-the-range turbocha six-cylinder, the T6.440, bE featured on the stand.

Rated at 160kW (215bhp' 2,600rpm and up to 19 (260bhp) with charge cool the T6.440 is well into its velopment programme ha% clocked up thousands of m on road testing.

Perkins is also showing new derivatives of existing gines which are available mediately. The four-cylin T4.236 has been developed vehicles in the five to 10-to category. Based on 1 naturally-aspirated 4.236, new engine incorpora controlled expansion pist and strengthening of the c) der block and head.

In its new turbocharged fc the T4.236 develops 75 (100bhp) at 2,600rpm.

The Motor Show is the major appearance of the upri. TV8.540 engine. This latest c

we of the 8.8-litre (540cuin) ;ign produces 1 7 5kW obhp) at 2,600rpm. Both this the current 160kW (215bhp) .ion will be available for use p to 34 tonnes, with derated Orpm variants being pos? for specific applications.

this article, I have concenId on the diesel engine side he drive line as being far e applicable to the heavy imercial vehicle than a petrol . Saab however, has proad what it calls APC (Auto:lc Performance Control) ;h is an interesting system ;h allows the engine to run uels of varying quality withthe need for readjustment.

ability to run on fuels of :rent quality is something many engineers are curly investigating with great rest, with Perkins, Mercedes and Renault being particu, aware of the problem.

ith the APC system on the la turbocharged petrol en:, the engine block is fitted

a knock sensor which des any abnormal running con-:ns in the engine and records knocking caused by excessi: high loads.

us sensor feeds the signals n electronic unit which gives necessary instructions to a Inoid valve located adjacent he turbocharger wastegate. electronic unit is also linked pressure sensor on the in manifold.

le knock sensor detects any king in the engine and sig to the electronic unit which rates the solenoid valve, s opening the pressure control valve. With this system Saab claims that the engine can run on fuels with octane ratings varying between 91 and 99 without any need for adjustment.

The system always tries to restore the boost to the maximum that the fuel quality will allow and so the aforementioned process can take place up to 12 times per second. In this respect it can be compared with Skid Chek or IVIaxaret, in the sense that the process takes place many times per second without the driver being aware of it.

The renamed Spicer Drivetrain Group is exhibiting a new 356mm (14in) ceramic faced angle ring clutch designed specifically for medium weight chassis in the 120 to 155kW (160 to 210bhp) category.

The angle ring design is claimed to give constant plate loading throughout the life of the facings. The pedal effort is 50 per cent lower than conventional units requiring only 14Kg (31Ib) pressure to release the angle ring clutch.

Charge-cooling makes its appearance on MAN vehicles for the first time in the UK although the company has used the concept for some time in mainland Europe. Two new engines are now available for installation in the 16.281, 16.321, and 19.321 tractive units. The latter is designed for 50 tonnes gcw while the other two are designed for 44 ton nes.