BigmBiggermBiggest!

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

44 verything's bigger up 'ere mate!"

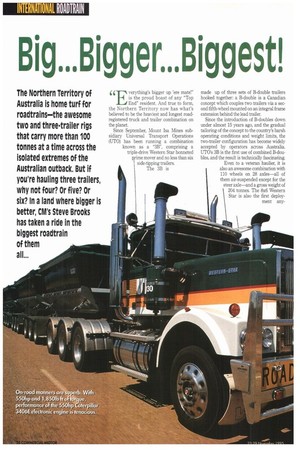

is the proud boast of any "Top End" resident. And true to form, the Northern Territory now has what's believed to be the heaviest and longest roadregistered truck and trailer combination on the planet.

Since September, Mount Isa Mines subsidiary Universal Transport Operations (UTO) has been running a combination known as a "3B", comprising a triple-drive Western Star bonneted rime mover and no less than six side-tipping trailers.

The 3B is made up of three sets of B-double trailers hooked together: a B-double is a Canadian concept which couples two trailers via a second fifth-wheel mounted on an integral frame extension behind the lead trailer.

Since the introduction of B-doubles down under almost 15 years ago, and the gradual tailoring of the concept to the country's harsh operating conditions and weight limits, the two-trailer configuration has become widely accepted by operators across Australia. UTO's 3B is the first use of combined B-doubles, and the result is technically fascinating.

Even to a veteran haulier, it is also an awesome combination with 110 wheels on 28 axles—all of them air-suspended except for the steer axle—and a gross weight of 204 tonnes. The 8x6 Western Star is also the first deploy ment any where in the world of a Caterpillar 3406E electronically controlled engine rated at 550hp.

Early next year UTO will put another 3B on the road, and big trucks for big jobs cost big bucks—the cost of the two rigs is nearly $A1.8m (f-860,000).

UTO's 38 roadtrain has been designed specifically to maximise the operational and environmental efficiencies of hauling zinc/lead concentrate from Mount Isa Mines' new McArthur River project, situated some 700km south-east of Darwin, capital of the Northern Territory, From McArthur River, the 55m-long 3B combination hauls its 136-tonne payload 120km north along a sealed road to a remote, but highly specialised, port facility at Bing Bong on the edge of the Gulf of Carpentaria in Australia's far north.

Despite the isolation of the area, UTO's 3B operates under strict environmental rules with the zinc/lead ore and extracted concentrate hardly ever seeing the light of day. Ore is mined underground, the concentrate is stored under cover and each of the roadtrain's six trailers are fitted with a semi-automatic hydraulic sheeting system.

Bing Bong

At Bing Bong the concentrate is unloaded inside a purpose-built shed before a fully enclosed conveyor belt system transfers it the last few hundred metres to a selfdischarging bulk barge which ferries 3,250tonne loads to bulk carriers moored about 30km further out in the gulf. It takes about four days to load a 25,000-tonne ship.

UTO general manager Kerry Noyes reckons the 3B is setting a new standard in road transport efficiency: "We're delighted with the productivity and overall performance of the combination" he says.

The world's heaviest roadtrain is very much a team effort. For its development UTO called in independent design consultants, experts from the Northern Territory Department of Transport and Works, as well as truck, trailer and specialist equipment

manufac

turers. The project began some 18 months ago, when Noyes commissioned transport engineering consultant Dr Peter Sweatman of Road User Research to generate a range of vehicle designs and combinations capable of meeting a wide range of transport needs— regardless of current practice and legislative constraints, "Based on this research, and a worldwide study of state-of-the-art hardware, UTO presented three options and its recommended configuration to the Northern Territory authorities," says Noyes.

The authorities quickly recognised that amending existing regulations for the proposed operation would improve safety and reduce road wear. It was decided to make the drive and all trailer axle groups tria.xle after research showed that triaxle combinations cause significantly less road wear than tandem groups. The combination's 55m overall length is just 1.5m greater than a conventional triple roadtrain.

With a kerbweight of around 68 tonnes no other existing roadtrain design capable of being registered for public road use came close to matching this standard of productivity, says Noyes.

The 3B development programme included computer modelling to predict how the rig would behave in an emergency that might require rapid manoeuvring.

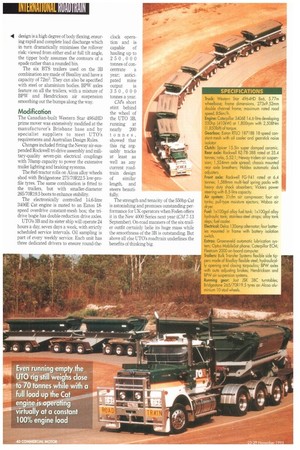

Road User Research ultimately developed computer software to model a 28-axle vehicle. Computer modelling was also used to establish optimum engine and transmission specifications with fuel consumption estimates. In the Northern Territory roadtrains typically return between 2,5 and 4mpg. UTO's 3B is still settling down but is unlikely to reach much beyond 2mpg. That's not so bad when you recall that even running empty the UTO rig weighs close to 70 tonnes, and with a full load up the Cat engine is operating virtually at a constant 100% engine load.

Noyes says that painstaking attention to design detail for the vehicle and its accessories—and for the associated infrastructures at the mine and port sites—has maximised operating efficiency.

A computerised dynamic weighbridge at the mine site, fast-fill refuelling and radio debriefing of the vehicle's on-board computer management system contribute to rapid turnround times arid maximum on-road time.

The 240km round trip takes about four and a quarter hours which includes loading, unloading and refuelling.

Prime mover A Wiggins fast-fill fuel system on the Western Star prime mover gives a fuel flow of 2501itimin compared with "normal" nozzle rates of 15-201itimin. This, says Noyes, cuts daily refuelling time from about an hour to just 12 minutes.

The 3B design team even matched the size of the Bulk Transfer Systems flexible side-tipping trailers with the capacity of the loader bucket at the McArthur River mine site.

Since the first prototype went to work in 1988, BTS's side-tippers, developed by Darwin-based Bernie Ostermeyer, have won considerable acclaim. The key to the trailer's 11°'

design is a high degree of body flexing, ensuring rapid and complete load discharge which in turn dramatically minimises the rollover risk: viewed from either end at full tilt angle, the tipper body assumes the contours of a spade rather than a rounded bin.

The six BTS trailers used on the 3B combination are made of Bisalloy and have a capacity of 72m3. They can also be specified with steel or aluminium bodies. BPW axles feature on all the trailers, with a mixture of BPW and Hendrickson air suspension smoothing out the bumps along the way.

Modification The Canadian-built Western Star 4964HD prime mover was extensively modified at the manufacturer's Brisbane base and by specialist suppliers to meet UTO's requirements and Australian Design Rules.

Changes included fitting the Neway air-suspended Rockwell tri-drive assembly and military-quality seven-pin electrical couplings with 70amp capacity to power the extensive trailer lighting and braking systems.

The 8x6 tractor rolls on Alcoa alloy wheels shod with Bridgestone 275/70R22.5 low-profile tyres. The same combination is fitted to the trailers, but with smaller-diameter 265/70R19.5 boots to enhance stability The electronically controlled 14.6-litre 3406E Cat engine is mated to an Eaton 18speed overdrive constant-mesh box; the tridrive bogie has double-reduction drive axles.

UTO's 3B and its sister ship will operate 24 hours a day, seven days a week, with strictly scheduled service intervals. Oil sampling is part of every weekly service. Each unit has three dedicated drivers to ensure round-the

clock operation and is capable of hauling up to 250,000 tonnes of con centrate a year; anticipated mine output is 350,000 tonnes a year.

CMs short stint behind the wheel of the UTO 3B, running at nearly 200 tonnes, showed that this rig arguably tracks at least as well as any current roadtrain design

of similar length, and steers beautifully.

The strength and tenacity of the 550hp Cat is astonishing and promises outstanding performance for UK operators when Foden offers it in the New 4000 Series next year (CM 7-13 September). On-road manners of the six-trailer outfit certainly belie its huge mass while the smoothness of the 3B is outstanding. But above all else UTO's roadtrain underlines the benefits of thinking big.