ADVANCED THOU( ST BRAKE DESIGN.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The Existence of Many Clever Ideas, Av for Improved De: runediate Adoption, which should Make ter Maintenance.

D RAKE efficiency spells safety in the operation of road vehicles, but as a subject it is, really, very little understood. Designers and makers follow worn grooves in providing their vehicles with brakes ; users and drivers suffer worn grooves and even worse defects in the brake gear of their vehicles, and this has now gone on for so long that one begins to recognize the probability that road safety is dependent upon luck more than on mechanical skill and excellence.

The number of mishaps, accidents and failures that has occurred in, we will say, only the past two years to motor lorries and coaches has been quite unreasonable. Each incident has made a small total impression, but generally throughout the road transport industry the whole of them put together have scarcely caused a flutter—or they would not have done but for the fact that The Commercial Motor has persistently called attention to the need for -a thorough reconsideration of brake design and for some official action which shall bring about the exercise of greater care in the examination, adjustment and maintenance of the brakes on every commercial vehicle.

We have carefully watched the trend of design in brakes and brake gear, and it seems that a useful purpose would, at a period when the thoughts of everybody are being turned to new ideas in chassis design, beserved by a survey of recent inventions, and in selecting those which particularly appeal to us as being real improvements we will confine ourselves to that class in which the brake expands within a drum, as most other kinds seem to be gradually waning in popularity. We shall also confine ourselves to the class in which the whole of the shoe can be brought into useful contact with its drum, as it is not unfair to regard shoes which are hung on an unadjustable hinge, or brake gear in which all the expansion for adjustment is at the cam-operated end, as being wrong in principle, because the greater part of the pressure and of the consequent wear is confined to that part of the, shoe which is farthest from the hinge or fulcrum.

Apart from this, such brakes are wrong, as they put a very unfair strain on the bearings on which the wheels are mounted, and they tend to pull the drum to a position which is eccentric with its bear• ing. The practice of faking up a brake as shown in Fig. 1 is a common method of dealing with the fault, but no one can claim that it is a proper mechanical job. Unless the man who does the work knows how to secure the screws which fasten the plates, by sinking their heads deeply and burring the metal over so as to prevent them working out, the screws and also the plates will sometimes become loose and will obstruct the cam from operating, or they may even fall off altogether. Bolts with nuts behind them cannot often be fitted in place of screws, nor can they be burred over at the ends.

In some cases art even worse method is adopted, consisting of the mere fit ting of a piece of plate and bending the edges over as in Fig. 2. Most users of vehicles will agree that something better than these dodges should be adopted. The well-known mode of adjustment in which a conical head is drawn in between the ends of the shoes in order to force them apart answers admirably for Fords and for other light vehicles, but it is hardly suitable for the heavier class of lorries. One of 'the simplest of the devices recently invented for the purpose of adjusting the set of the shoes is that shown in Fig. 3, patented by the Compagnie d'Applications Mecaniques, in which a double volute cam is employed to force the ends of the shoes apart along the slots shown. The bulb ends of the shoes form the hinge on which they swing, whilst the adjusting cam can be locked in any desired position. Although this class of adjustment does not actually ensure contact between the whole length of the shoe and the drum, it permits of proper adjustment, provided the maintenance staff will take the trouble to attend to it, In these matters we hold that the proprietor of a fleet

Fig. 3. One of the h the adjustment of double volute cam i left when the brake the position shown

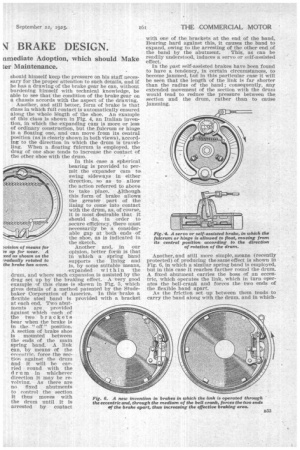

should himself keep the pressure on his staff necessary for the proper attention to such details, and if he has a drawing of the brake gear he can, without burdening himself with technical knowledge, be able to see that the condition of the brake gear on a chassis accords with the aspect of the drawing. Another, and still better, form of brake is that class in which full contact is automatically ensured along the whole le-ngth of the shoe. An example of this class is shown in Fig. 4, an Italian invention, in which the expanding cam is more or less of ordinary construction, but the fulcrum or hinge is a floating one, and can move from its central position ( as is clearly shown in both views), according to the direction in which the drum is travelling. When a floating fulcrum is employed, the drag of one shoe tends to increase the contact of the other shoe with the drum.

In this case a spherical bearing is provided to permit the expander cam to swing sideways in either direction, so as to allow the action referred to above to take place. Although this form of brake allows the greater part of the lining to come into contact with the drum, as, of course, it is most desirable that it should do, in order to secure efficiency, there must necessarily be a considerable gap at both ends of the shoe, as is indicated in the sketch.

Another and, in our opinion, better form is that in which a spring hand supports the lining and is, by some suitable means, with one of the brackets at the end of the band. Bearing hard against this, it causes the band to expand, owing to the arresting of the other end of the band by the abutment, This, as can be readily understood, induces a servo or self-assisted effect.

In the past self-assisted brakes have been found to have a tendency, in certain circumstances, to become jammed, but in this particular case it will be seen that the length of the link is far shorter than the radius of the band ; consequently, any extended movement of the section with the drum would tend to reduce the pressure between the section and the drum, rather than to cause jamming.

Another, and still more simple, means (recently protected) of producing the same effect is shown in Fig. 0, in which a similar spring band is employed, but in this case it reaches farther round the drum. A fixed abutment carries the boss of an eccentric, which operates the link, which in turn operates the bell-crank and forces the two ends of the flexible band apart. As the friction set up between them tends to carry the band along with the drum. and in which

ever direction the drum may be revolving, one of the ends of the spring must be arrested by the abutment and so cause the band to tend to expand, and by so doing create a self-assisted effect. Here, again, it will be seen that the operating link is capable of swinging to either side so as to permit of movement of the band in the direction of rotation, also that, owing to the length of the link being less than the radius of the drum, no jamming effect is possible. Small projections are arranged at intervals round the circle, against which the band can recoil when in the " off " position. These projections can be turned whilst the operation of boring of the non-revolving flange is taking place in the course of manufacture, and they form the only supports necessary for centring the brake when not in operation.

It is a well-known fact that, in the design of brakes for the heavier classes of vehicles, one finds oneself between two difficulties. On the one hand ample power capable of quick application is necessary; on the other, the limitations of the human frame demand a short lever, and clearance between brake and drum and shoes is unavoidable. If the ratio of the leverage between the foot or hand lever and the levers which operate the expander cam be such as to produce the desired re tarding effect, there is always . IDLE the possibility of the movement STROKE great that it becomes inconvenient to the driver. Foot and hand levers can only conveniently operate through an angle of from 15 degrees to 20 degrees, and it is only with the greatest care on the part of the designer that the available force, namely, the strength of leg or arm of the driver, can be applied so as to produce the required retarding effect, without undue exertion, or involving too extended a movement of foot or hand.

It is well recognized that the movement of foot or hand may roughly be divided into two separate operations. The first half of the movement is merely to take up clearance and to b ring t he shoes into contact with their drums. whilst the second half of the movement of such levers is devoted to the actual application of the brakes after being brought into contact. We may call the first of such movements the idle stroke, and the second the power stroke. For the idle stroke it is not necessary to have any great amount of leverage, but, for the power stroke, one wants all the leverage obtainable.

POWER STROKE1

The Object of the Recently Introduced "Booster" and What it Accomplishes.

In the ordinary brake arrangement, the ratio remains the same throughout theb whole stroke, but Figs. 7 and S show two forms of a recent invention called a'" Booster," the object of which is to enable a leverage of as much as double that usually employed to be used during the power stroke, without increasing the movement of foot or hand levers.

This may at first sound paradoxical, but the effect is produced by introducing a simple cam, acting against a roller anchored to any convenient part of the frame. The effect of this is to hasten or " boost " the movement of the pull-rod during the first half of the travel, or through what may be called the idle stroke. After this the cam ceases to operate in hastenipg the movement of the pull-rod, which then is as if it were connected dir&tly to its lever. By the aid of this device the levers which operate the expanding cam can be doubled in length so as to double the braking effect, but without increasing the movement of foot or hand lever. Fig. 7 shows the device fitted direct to a foot lever, whilst Fig. 8 shows it inserted, in one of the pull-rods. This device is, we believe, actually on the market, and can be fitted to an chassis.

The Need for Further Research Work in the Selection of Materials for Brake Linings.

The selection of the most suitable materials for the lining of brakes for commercial vehicles has, of course, received attention, but we do not think that there has been sufficient research work done in this direction. The brakes of a commercial vehicle present a very different problem to the designer from that involved in their design for private cars, or for use on the railway.

The conditions prevailing in connection with tramcars used in hilly country come nearest in all probability to those appertaining to the commercial lorry, but even in the case of tramcars there seems less trouble to contend with than on the lorry, owing to the fact that the lorry is shod with a type of tyre which cannot have a brake applied directly to it. Were it possible for the brakes of a lorry to impinge directly on the tyre matters would be easier. When one considers the enormous amount of energy that has to be dissipated when descending a long and steep hill with a heavy load, it would seem that something better than the materials known to-day might have been found had more research work been devoted to the matter.

At the recent inquest in Yorkshire, the "burning out" of brakes was freely mentioned. A correspondent in our issue of the 4th inst., says : "I am open to gamble that I could burn out a newly-lined footbrake on one journey to Manchester with a 5-ton load." In the face of these instances and other evidence, we are of the opinion that metal-to-metal brakes may yet come, provided that the right alloys for both drum and linings were better investigated.