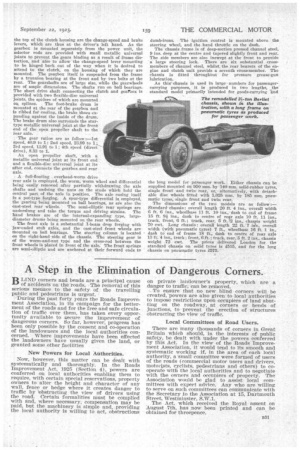

IMPROVEMENTS IN A 3 - -TON FRENCH CHASSIS.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

ModiEcitions which are Aimed to Render the Chassis, when Mounted on Pneumatic Tyres, Suitable for Passenger Work.

IT is now seine four years since Automobiles M. Berliet, of 40, Sackville Street, London, W.1, placed their liveaxle 34-ton chassis on the market, and during that period this chassis has met with very considerable success, not only in the United Kingdom, but also overseas, numbers having been shipped to Australia and other parts of the world.

In line with the makers' policy of continually striving to improve their productions and to embody therein the latest improvements in automobile engineering, this chassis has had embodied in its design a number of new features, which will be appreciated by all who are users of commercial vehicles.

On Arst examination of the latest edition of this chassis, the principal alteration that meets the eye is the fitting of detachable cylinder heads to the power unit, but the improvements go farther than this, as will be seen from the following description of the new chassis.

The engine, as heretofore, has four cylinders cast in pairs, having a bore of 110 mm. and stroke of 140-mm. The rated horse-power is 30 and the brake horse-power developed at 1,350 r.p.m. 38. The cylinders of the new engine have detachable heads to each block of two cylinders and are bolted to the upper half of the aluminium crankcase, which also carries the crankshaft main bearings. These bearings are of bronze, lined with White metal, their caps beings held in

• place by four bolts each. The bearings are of ample size, their respective lengths being as follow: front bearing 31 ins., centre bearing 53 ins., rear bearing 41 ins. The bigend bearings are of similar construction to the, main bearings and their caps are also held in place by four bolts each. The camshaft is located on the left-hand side of the engine and is carried in phosphor-bronze bushes, the camshaft drive being by helical-toothed gearing from the crankshaft. One camshaft operates all the valves.

Located on the left side of the engine and driven by skew gearing from the crankshaft is the centrifugal governor. Set to " cut-in " at 1,350 r.p.m. and operating a separate butterfly in the induction pipe, the governor is totally enclosed and the casing sealed. Driftn by skew gearing from the timing gear and positioned across the front of the engine, B30 at right angles to the crankshaft, is a cross-shaft, which drives at one end the centrifugal water pump and at the other end the magneto, the latter so positioned that, on opening the right side of the bonnet, the make-and-break faces outwards.

The pistons are of cast-iron and have three rings, all located above the gudgeon pin, which latter is locked in the piston by a setscrew and oscillates in a phosphor-bronze bush in the connecting rod smalhend. Provision is made for fitting a single-unit starter-dynamo on the right-hand side of -the engine, the dynamotor being driven by a silent Chain from the crankshaft, with a jockey pulley mounted on an eccentric to provide for chain adjustment. An eccentric is also provided on the fan spindle for tensioning the fan belt. The lower half of the crankcase is divided longitudinally into twn sections, the lower section being the oil sump, which is protected by a gauze screen running the full length of the crankcase. Located in the sump and driven by skew gearing from the camshaft is the gearwheel oil pump, which delivers oil under pressure to the crankshaft main bearings, whence it flows through ducts in the crank webs to the big-end bearings, as well as to the camshaft bearings and over the timing gears. The cylinder walls, pistons, etc., are lubricated by oil thrown off from the revolving camshaft.

The front end of the timing case is extended forward and is carried in a sintle trunnion bearing in the dropped front cross-member of the chassis frame. At the rear end the crankcase is bolted to a bell housing surrounding the clutch and flywheel, which housing has two arms cast integral with it, these arms being bolted to the chassis side members. The engine is thus three-point suspended.

Carburation is attended to by a component of Bernet design and manufacture, which is supplied with petrol from a tank carried at the rear of the frame through the intermediary of a vacuum tank mounted on the dash.

A. gilled-tube radiator with detachable top and bottom tanks is mounted at the forward end of the chassis.

From the engine the drive is taken by a multiple dryplate clutch to the four-speed-and-reverse gearbox. The clutch is, as mentioned above, totally enclosed. Mounted on the top of the clutch housing are the change-speed and brake levers, which are thus at the driver's left hand. As the gearbox is mounted separately from the power unit, the selector rods are provided with small metallic universal joints to prevent the gears binding as a result of frame distortion, and also to allow • the change-speed lever mounting to be hinged back out of the way when it is desired to attend to the clutch, on the housing of which they are mounted. The gearbox itself is suspended from the frame by a trunnion bearing at the front and by two bolts at the rear. The gearshafts are of large size, while the gearwheels are of ample dimensions. The shafts run on ball bearings. The short drive shaft connecting the clutch and geafoox is provided with two flexible-disc universal joints, the spiders of which are mounted oil splines. The foot-brake drum is mounted at the rear of the gearbox and is ribbed for cooling, the brake shoes expending against the inside of the drum. The brake drum also surrounds the startype metallic universal joint at the front end of the open propeller shaft to the rear axle.

The gear ratios are as follow :-1st speed, 40.9 to 1; 2nd speed, 23.99 to 1 • 3rd speed, 13.91 to 1; 4th speed (direct drive), 8.33 to 1.

An open propeller shaft, with a metallic universal joint at its front end and a flexible-disc universal joint at its after end, connects the gearbox and rear axle.

A full-floating overhead-worm drive rear axle is employed, the worm, worm wheel and differential being easily removed after partially withdrawing the axle shafts and undoing the nuts on the studs which hold the central part of the axle in position. The axle casing itself is a pot-type forging. A spur-type differential is, employed, the gearing being mounted on ball bearings, as are also the

cast-steel rear wheels. The semi-elliptic rear springs are underslung and take the torque and driving strains. The hand brakes are of the internal-expanding type, largediameter drums being mounted on the rear wheels.

The front axle is a substantial 1-beam drop forging with -jaw-ended stub axles, and the cast-steel front wheels are mounted on ball bearings. The steering column is located on the right-hand side of the chassis. The steering gear is of the worm-and-nut type and the cross-rod between the front wheels is placed in front of the axle: The front springs are semi-dliptic and are anchored at their forward ends to

dumb-irons. The ignition control is mounted above the steering wheel, and the hand throttle on the dash. The chassis frame is of deep-section pressed channel steel, 9 ins, deep at the centre and tapered slightly front and rear. The side members are also inswept at the front to provide a large steering lock. There are six substantial crossmembers of channel steel, whilst, the rear bearers of the engine and clutch unit provide a seventh cross-member. The chassis is fitted throughbut for pressure grease-gun lubrication.

As this chassis is used in large numbers for passengercarrying purposes, it is produced in two lengths, the standard model primarily intended for goods-carrying and

the long model for passenger work. Either chassis can be supplied mounted on 950 mm. by 140 ram, solid-rubber tyres, single front and twin rear, or, alternatively, with detachable disc wheels fitted with 1,025 mm. by 185 mm. pneumatic tyres, single front and twin rear.

The dimensions of the two models are as follow:— Standard chassis: overall length 20 ft. 4 ins., overall width 6 ft. 6 ins., wheelbase 11 ft. 10 ins., dash to end of frame 15 ft. 9f ins., dash to centre of rear axle 10 ft. 11 ins., track, front, 6 ft. ; track, rear, 5 ft. 12 ins., chassis weight 70 cwt. Long chassis: overall length 22 ft. 7 ids., overall width (with pneumatic tyres) 7 ft., wheelbase 18 ft. 1 in., dash to end of frame 18 ft., dash to centre of rear axle 12 ft. 4 ins., track ; front, 8 ft. ; track, rear; 5 ft. 2 ins.' chassis weight 72 cwt. The prices delivered London for the standard chassis on solid tyres is £515, and for the long chassis on pneumatic tyres £575.