New Dumper for Site and Road Wort

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

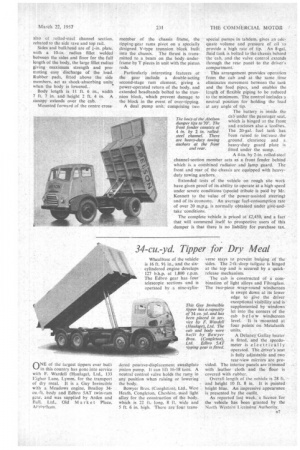

ANEW dumper based on • an Austin 701 chassis of 10-ft, wheelbase, -and suitable for site as well as road work, has been built by Abelson and Co. (Engineers), Ltd., Sheldon, Birmingham. They are among the largest suppliers of contractors' plant in the country and have detailed knowledge of earth-moving, problems. The new model has a payload capacitN

of 9 tons. _

Explaining to The Commercial Motor his decision some 12 months ago to build a dumper based on a standard chassis, for which spare parts could easily be obtained, Mr. A. W. Kennett, a director of the company, said, "We had long felt the need in the civilengineering, contracting and quarrying business for a robust on-and-off-theroad earth-moving dumper which could be used also for rock, stone, gravel and so on, with a capacity of about 6 cu. yd. or a.9-ton rating and available at a competitive price."

Meeting a Need In recent years, he added, civil engineers had employed 4+ or 5-cu.-yd. -tippers which met their requirements within reasonable limits for road work. but had not been satisfactory for site haulage. The Abelson dumper is claimed to offer the tdvantages that Mr. Kennett sought.

The chassis has an Austin cab and the B.M.C. 5-litre oil engine, which develops 105 b.h.p. at 2,600 r.p.m. and a maximum torque of 232 lb.-ft. at 1,750 r.p.m. An Eaton two-speed axle provides ratios of 6.14 to 1 and 8.54 to 1. Steering is power-assisted.

With a struck capacity of 5 cu. yd., the heaped capacity of the body is 7 cu. yd. Special heavy-duty twin-ram underbody gear gives a 70° angle of tip, and the 25° scow end avoids spillage in normal operations. The vehicle weighs 5+ tons unladen. , A full-length sub-frame extending to the front of the vehicle comprises 5-in. by 2+-in, rolled-steel channel sections welded to the main chassis members and reinforced on the outside by +-in. steel plates 14 in. deep. Rolled-steel members are employed as a preferable alternative to the pressed-steel type, and the fabrication of the sub-frame and reinforcing plates is such that local stress concentrations are avoided.

Hydraulic double acting shock absorbers are fitted to the front and rear axles. The springs are of the standard type, but the rear springhanger brackets are attached with seven bolts in place of four, use being made of existing holes in the chassis members for the extra bolts.

The rear axle is mounted on the springs by means of robust support shoes with long U-bolts. In place of• the standard 8.25-20-in. 12-ply tyres, 9X/0-20-in. 12-ply covers are now fitted on the front wheels, and the rear wheels are equipped with 10.00-20-in. 12-ply tyres.

The all-steel electrically welded body has a double-skin floor of 1-in. steel plates with a hardwood sandwich. Rolled-steel longittidinals of '4-its. by 2-in. channel section are used for the underframe. The front and rear cross-members are of 4-in. by 2-in. rolled-steel channel section and the intermediate cross-bearers are of 4-in. by 1+-in. pressed steel channel, all the members being individually welded to the longitudinals.

Side sills and top rails are of -4-in. by 2-in. rolled steel channel. Vertical members are also of rolled-steel channel section, rebated to the side rave and top rail.

Sides and bulkhead are of *-in. plate, with a 10-in. radius fillet welded between the sides and floor for the full length of the body, the large fillet radius giving maximum strength and promoting easy discharge of the load. Rubber pads, fitted above the side members, act as shock-absorbing units. when the body is lowered..

Body length is 11 ft. 6 in., width 7 ft. 7 in. and height 2 ft. 4 in. A canopy extends over the cab.

Mounted forward of the centre cross member of the chassis frame, the tipping-gear rams pivot on a specialty designed V-type trunnion block built

into the chassis. The thrust is transmitted to a beam on the body underframe by T pieces in unit with the piston rods.

Particularly interesting features ot the gear include a double-acting second-stage ram element, giving a power-operated return of the body, and extended headbands bolted to the trunnion block, which prevent damage to the block in the event of over-tipping.

A dual pump unit; comprising two special pumps in tandem,. gives an adequate volume and pressure of oil to provide a high rate of tip. An 8-gal. fluid tank is bolted to the chassis behind the cab, and the valve control extends through, the rear panel to the driver's compartment.

This arrangement provides operation from the cab and at the same time eliminates movement between the tank and the feed pipes, and enables the length of flexible piping to be reduced to the minimum. The control includes a neutral position for holding the load at any angle of tip, The battery is inside the cab under the pa;senger seat, which is hinged at the front and encloses also a toolbox. The 20-gal. fuel tank has been raised to increase the ground clearance and a heavy-duty guard plate is fitted under the sump.

A 4-in. by 2-in, rolled-steel channel-section member acts as a front fender behind which is a combined radiator and lamp guard. The front arid rear of the chassis are equipped with heavyduty towing anchors_

Extended tests of the vehicle on rough site work have given proof of its ability to operate at a high speed under severe conditions (special tribute is paid by Mr. Kennett to the .value of the power-assisted steering) and of its economy. An average fuel-consumption rate of over 20 m.p.g. is normally obtained under give-andtake -conditions.

The complete vehicle is priced at £2,450, and a fact that will commend itself to Prospective users Of this dumper is that there is no liability for purchase tax.