A.E.C.'s BE

Page 50

Page 51

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

HEAVY" YET

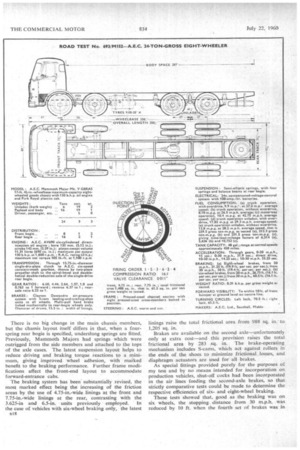

IMPROVED appearance is a relatively minor advantage of the latest A.E.C. Mammoth' Major eight-wheeled

goods chassis. The road performance makes this comparatively new design the best heavy goods chassis ever to haye been manufactured by this concern, and puts it well into the top rank of all the heavy goods vehicles of this type at present constructed in Great Britain.

The example tested had the AV690 11.3-litre oil engine and overdrive-top gearbox combination, giving a maximum speed of 50 m.p.h., but, more important, outstanding fuel economy. When tested under simulated trunk conditions, 9.9 m.p.g. was returned at an average speed of 27.2 m.p.h., whilst a full-throttle run along 26 miles of the Londor Birmingham motorway at an average speed of 42.75 m.p.1 realized a consumption rate of 10.4 m.p.g. For a full laden eight-wheeler these figures must create an econom record: certainly the time-load-mileage factor of 10,73: achieved on the motorway, is appreciably above norma The well-spaced intermediate ratios of the A.E.0 gea. box and the 505 lb.-ft. torque output of the engine con bine to give particularly vigorous acceleration and live] hilt-climbing. Moreover, with eight-wheel brakes 0retardation power reaches a notably high standar4 although even with six-wheel brakes it leaves little to t desired for a vehicle of this weight. Driving conditions generally are good, although the steering tends to be a little heavy and cab ventilation is hardly adequate for British summer temperatures. The frame layout is such that the cab-entry steps are placed ahead of the front wheels, so that access to the driving seat is particularly easy. The overall range of vision is good, too, the deep curved windscreen panels giving ground-level vision to within 10 ft. of the front bumper when measured on the vehicle centre line.

The current range of

Mammoth Major multi-wheeled goods chassis was intro. duced in the late summer of 1958 for the Commercial Motoi Show of that year. The designs signified a radical depart ture from Mark III models of the same type name, not thi least of the differences being the introduction of two nev power units to replace the original 9.6-litre and 11.3-litre engines.

Although on paper the AV590 and AV690 engines which replace the earlier units, appear identical, both ir respect of dimensions and outputs, there is a noticeable difference in the installed performances—difference: which make for greater economy with a wider margir of usable power.

Either of the two power units may be specified foi vehicles in the Mammoth Major range. The smallei engine has a gross output of 125 b.h.p. at 1,800 r.p.m. compared with the 150 b.h.p. output of the large] engine at the same speed, or 165 b.h.p. at 2,000 r.p.m My tests with the eight-wheeler showed that, because the 150 b.h.p. unit does not have to be worked sc hard during normal operation, it is probably more economical in use than the smaller engine would be whilst its life between major overhauls should be longer.

The standard gearbox supplied with both power units has five speeds and is almost identical to thai employed in earlier models, with the exception of a new change-speed unit and modifications to accept hydraulic clutch actuation. As with the earlier box, a sixth overdrive ratio of 0.763 to 1 is available. This additional gear was in the gearbox of the test chassis.

When, as in the case of the vehicle tested, a single-drive rear bogie is used, the driving axle is a double-reduction unit. Overhead-worm-drive axles are employed in doubledrive bogies.

The double-reduction axle is available with a choice of three final-drive ratios: 7.92, 7.12 or,as tested, 6.22 to 1, The worm axle is offered with ratios of 10.33, 7.75 or 6.4 to 1. All these optional ratios in the case of both axles are the same as -with earlier chassis,. There is no big change in the main chassis, members, but the chassis layout itself differs in that, when a fourspring rear bogie is specified, underslung springs are fitted. Previously, Mammoth Majors had springs which were outrigged from the side members and attached to the tops of the axle cases. The latest suspension layout helps to reduce driving and braking torque reactions to a minimum, giving improved wheel adhesion, with marked benefit to the braking performance. Further frame modifications affect the front-end layout to accommodate forward-entrance cabs.

The braking system has been substantially revised, the most marked effect being the increasing of the friction areas by the use of 4.75-in.-wide linings at the front and 7.75-in.-wide linings at the rear, contrasting with the 3.625-in and 6.5-in, units previously employed. In the case of vehicles with six-wheel braking only, the latest

e18 linings raise the total frictional area from 988 sq. in.to 1,205 sq. in.

Brakes are available on the second axle-unfortunately only at extra cost-and this provision raises the total frictional area by 283 sq. in. The brake-operating mechanism includes S-cams, which act against rollers in the ends of the shoes to minimize frictional_ losses, and diaphragm actuators are used for all brakes.

As special fittings provided purely for the purposes of my test and by no means intended for incorporation on production vehicles, shut-off cocks had been incorporated in the air lines feeding the second-axle brakes, so that strictly comparative tests could be made to determine the respective efficiencies of sixand eight-wheel braking.

These tests showed that, good as the braking was on six wheels, the stopping distance from 30 m.p.h. was reduced by 10 ft. when the fourth set of brakes was in operation. Subsequent fade-resistance trials showed a similar marked difference. Despite the extra cost and the 3 cwt. added to the unladen chassis weight, I cannot recommend operators strongly enough to specify brakes on all wheels.

A further safety device offered as optional equipment at additional cost is an Ashanco electrically operated exhaust brake, which is controlled by a switch on the pedal pad. The wheel brakes cannot be used without the exhaust brake also taking effect, thus saving wear and tear of the wheel brakes. A split-circuit air-pressure system can, at extra cost, be supplied to give further braking safety.

The test chassis had a wheelbase of 17 ft. 44 in. This is the longest of the three available wheelbases, the others being 14 ft. 8 in. and 16 ft. The cab was the new Park Royal plastics assembly, which has been designed to mount directly on to the standard A.E.C. cab base. A composite coachbuilt cab of similar layout and appearance is also available.

A gross vehicle weight rating of 25 tons is specified for Mammoth Major eight-wheelers with four-spring rear bogies, but models with the fully articulated two-spring bogie may be operated at 28 tons gross, subject to legisla tion. Only slight modifications would be necessary, however, to suit four-spring models for 28 tons gross. The maximum permissible gross train weight for single-drive models is 36 tons, 40 tons being specified for tandemdrive chassis. Tyres of up to 11.00-22-in. section can be fitted, the test vehicle having Michelin " X" 9.00-20-in. equipment.

The kerb weight, complete with cab, was 6 tons 194 cwt., and cast-iron blocks totalling 16 tons 19 cwt. had been secured to the chassis frame to represent a body and payload. Allowing about ton for a light-alloy platform body, this would give a payload capacity of 164 tons. With myself and two A.E.C. representatives aboard, the gross weight was 24 tons 34 cwt., and all 12 tyres were almost equally loaded.

Braking tests were carried out first, and the first set of figures was taken with all eight brakes in operation. Stops from both 20 m.p.h. and 30 m.p.h. produced locking of all the rear wheels. The front tyres marked the road surface heavily, indicating that the front brakes were operating at peak efficiency.

Good Stopping Distances

Extremely good stopping distances were recorded from both speeds and high Tapley meter readings—including one of 90 per cent.----were achieved. There appeared to be little delay in the air-pressure system and the general braking effect was satisfactorily smooth and grab-free.

The second-axle brakes were then cut out and the tests repeated. All the rear-bogie wheels again locked, but the reduction in braking area increased the stopping distances by 5.5 ft. from 20 m.p.h. and 10.5 ft. from 30 mph, Even so, the retardation rates recorded with only six of the brakes in action were well above average for a six-wheelbraked eight-wheeler.

The same stretch of road in the Southall area was used for acceleration tests. Here, again, extremely good figures were obtained. The time taken to reach 30 m.p.h. from a standstill was less than is often required with vehicles running at well under half the weight of the A.E.C., whilst the direct-drive times accentuated the good torque characteristics of the AV690 power unit.

Although the A.E,C. gearbox does not have synchromesh engagement, fast changes can easily be made, partly because the engine speed dies down quickly when the throttle is released and the clutch is disengaged. Five sets of fuel-consumption tests were made in all, four of these being on a 12-mile out-and-return circuit of Western Avenue, to give representative results for normal trunk operation. Two of these runs were made • laden, using the overdrive on one in the normal manner and the other without it, as would be the case with the standard five-speed gearbox. Later, these two runs were repeated unladen, with the test chassis carrying only one • iron weight and the gross weight reduced to 7 tons 12 cwt.

• All •four fuel figures obtained were outstanding, and reference to the data panel shows the marked improvement in consumption rates which can be expected from use of the overdrive gearbox. When laden, the overdrive ratio gave an improvement of 13 per cent., whilst unladen it was more than 31 per cent.

Combination of the two sets of figures obtained with and without overdrive shows that operators of tankers and similar vehicles which spend half their running time unladen can expect a clear 13 m.p.g. overall with overdrive and about 11 m.p.g. without overdrive. In each case, the figures illustrate the degree of economy of which operators often speak but very rarely obtain.

10.4 m.p.g. on Motorway

The fifth consumption test was made over a 26-mile stretch of the motorway at continuous full-throttle. After this run the fuel-test tank indicated a consumption rate of 10.4 m.p.g.—again an exceptional result, particularly in view of the high average speed of 42.75 rn.p.h. A typical run between London and Birmingham by way of the motorway should be passible with an overall consumption rate no heavier than 10 m.p.g.

For hill-performance tests I took the eight-wheeler to Bison Hill, a 4-mile climb with an average gradient a 1 in In The ambient temperature during these tests was 66°F. Before the climb the coolant temperature was 164°F. and a fast ascent, which took only five minutes, caused it to rise to 193°F. This is somewhat high, but the cooling system is pressurized to raise the boiling point to over 230°F. As it was, when the filler cap was removed to take the temperature, the cooling water bubbled out of the neck and some was lost.

The lowest gear used during the climb was second and this was engaged for 2 minutes 7 seconds, during which time the road speed never fell below 6 m.p.h. This sort of performance shows that, with its big engine, the latest A.E.C. eight-wheeler should not be such a source of frustration to private motorists on normal main-road hills as many of its less highly powered and undergeared contemporaries.

Two fade tests were made, and for the first I used all eight brakes. I coasted down the hill in neutral while keeping the speed to 20 m.p.h. by use of the foot brake, and after 24 minutes a full-pressure stop from the same seed produced a Tapley meter reading of 61 per cent—an efficiency reduction of only 20 per cent.

The second descent was made, after the drums had cooled, with six-wheel brakes only. After this test the maximum efficiency had fallen to 40 per cent,, which is exactly half that obtained with cold drums. Again the advantage of eight-wheel braking is highlighted.

After these fade tests I drove up to the steepest part of the hill, where the gradient is 1 in 64. Here the vehicle was stopped, but the hand brake would not hold it until helped on by partial application of the foot brake. A second-gear restart failed because of clutch slip and initially there seemed to be some doubt whether it was going to be possible to pull away in bottom gear.

This was not because of inadequate power, but because the off-side driving wheel spun when the clutch was n19 engaged. However, judicious manipulation of the clutch and throttle pedals eventually resulted in the right combination being found and the eight-wheeler pulled away satisfactorily. A double-drive bogie should not, of course, have been subject to this defect, particularly when a thirddifferential lock was fitted, although such a lock is not offered with A.E.C. chassis.

The Mammoth Major eight-wheeler is a pleasant vehicle to drive and ride in, except in hot weather, when the absence of adequate ventilation becomes rather overpowering. Engine noise is surprisingly low, even when running on the governor. Stowage space, in the cab is hardly adequate, but the cab finish is generally good, and the all-round vision is first-rate.

The steering at low speeds is probably no heavier than on some Other makes of eight-wheeler, and a servo is available at extra cost. On the open road the steering is pleasant and the vehicle handles in a stable manner, even the softness of the front suspe-nsion having no adverse effect on the steering characteristics, although cab bounce

can become excessive. .

The clutch pedal of the test vehicle was surprisingly heavy to operate, but the gear change was generally good, although a little stiff to get into overdrive position at times. The multi-pull hand-brake Iever has a rather difficult action, which makes it easy to accidentally release the brake while pumping it on.

Because of the use of a conventional pedal, the brakes, although they could be fierce when the chassis is unladen, have a good degree of " feel " about them and are easy to control.

The amount of road .work • carried out left no time in which to do maintenance tests, but the Mammoth Major should be about average in this respect. Engine access is reasonable, the cowling consisting of an upper hinged panel which opens from the near side, and a completely removable panel down to floor level on the near side. A stay holds the upper section in the raised position.

The latest A.E.C. eight-wheeler is, all in all, a wellbalanced, high-performance, high-quality design which offers innumerable advantages over its predecessors and represents one of the biggest advances in vehicle design made in one step by any manufacturer. Without resorting to unconventional techniques, A.E.C., Ltd., have produced a vehicle with widespread appeal to operators and drivers. Speed, economy, good appearance and ease of driving are much-sought-after qualities rarely to be found combined in a unit.