The New NieCurd 3-ton Wagon.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

First Description of a Sturdy Model which it will Puzzle the Driver to Abuse. It is of a Type which should Appeal Strongly to Capable Agents.

Mr. W. A. ..11cCurd is a gentleman who has an exceptional business reputation in regard to the pleasure-car branch of the motorvehicle industry. He conducts a wonderful business in connection with both new and second-hand cars at his headquarters in Store Street, Tottenham Court _Road. There. story after story of a mostcapacious and suitable building is stacked with valuable cars of all types. In addition, there is a big overhaul and repair department in the basement.

Things Which Should Not Happen.

We are led to introduce the present notice as we have done in order to emphasize the fact that Mr. McCurd has, during many years of practical experience, accumulated a wealth of information in regard to the things that should not be allowed to happen in respect of the running and maintenance of motor vehicles of all kinds. He speaks with a thorough knowledge of his subject when he talks of the manner in which components should be able to be dismounted. Few people know better than he does the evils which are wrought in all parts of a well-built chassis by defective lubrication, or by neglect of regular small adjustments when they are wanted. He has acquired, in the course of a busy career, a remarkable acquaintance with the manner in which the actual driver or owner, contradistinction to the theoretical ones of whom the ordinary salesman is somewhat apt to prate, is tempted to disregard chassis components which, for the time being, are giving him no trouble. He knows well the man who is content to let well alone.

The Limitations of the Foolproof.

It is this last characteristic which has found reflection so markedly in Mr. McCurd's new design of 3-ton industrial chassis. He has indubitably considered with care the type of man who will drive his chassis. He has gauged with considerable accuracy the amount of intelligence and of application which can legitimately be expected from such an employe. And, last but not least, he has carefully considered the man who is to sell the machine, what he has to get out of it, and what points he has to have ready at hand to emphasize his claims to the attention of a would-be user.

An Absence of "Frills."

The new McCurd chassis is, therefore, a very interesting one, and its design bristles with points which reveal careful consideration, and the resulth of a good deal of "cut and come again." There is no freakish embodiment of unusual transmission gear, nor has there been any attempt to eliminate the more ordinary components which have now been tried so thoroughly, and proved by users and makers alike the world over.

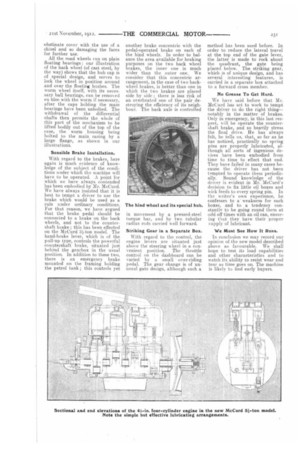

The four-cylinder vertical engine drives through a leather cone clutch to a spur change-speed gearbox, and thence by propeller shaft to a worm-driven back axle. So far there appears to be nothing startling about the chassis, but it is in regard to careful consideration of detail that we shall find most to impress us. We have secured a number of special photographs for this journal, and the reproduction of these on this and the following pages will serve to afford our readers an excellent idea of the type of construction which has been embodied.

Interesting Oiling.

The four-cylin(ler engine, of which we reproduce a drawing, has its poppet valves on opposite sides, and develops 42 it.p. at 1080 r.p.m. The most-noticeable features of its design are the very ample ,thermo-syphon, watercooling pipes, with their free bends and junctions, the provision of a spare magneto carried on the opposite side of the engine to that on which the one which is normally in use is situated, and the employment of a very simple, but what appears to be a very effective, method of engine lubrication. This is best illustrated by the drawing to which we have already referred. A reciprocating plunger pump, driven from the camshaft on the near side of the engine, with the barrel situated in the sump at the bottom of the crankcase, pimps oil into the four separate compartments in the lower half of the crank chamber. Running through these from end to end of the case is a plain piece of steel tube carried in small journals. This tube is drilled so that the overflow from the divisions may be regulated by turning it in its own journals. This is effected by a simple regulating screw situated outside the top half of the case. The flywheel is of exceptional diameter for an engine of this size, and accommodates a large leatherlined cone clutch, of which the spring control is very cutely housed concentrically over the ballbearing mounting at the exended end of the crankshaft. Evidence of Mr. McCurd's desire to secure rapid dissembling is particularly forthcoming in regard to the clutchoperating mechanism. The whole of the clutch-operating gear is situated at the off side of the main shaft, and the actual fork which withdraws the clutch against the spring bears against a thrust ball bearing, which is mounted half way between the clutch and the universal joint at the front end of the gearbox. It is therefore possible to withdraw the leather-lined clutch member, as well as its shaft and spring, without in any way dismantling the clutchoperating gear—a most useful feature. The actual levers serving to operate the clutch are illustrated in one of our reproductions.

No Keys in the Gearbox.

Of the gearbox itself, there is little to say, except that it is of conventional design in general, but of very substantial proportions. and yet as compact as the skill of a careful draughtsman will permit. It is interesting to note that the gears on the main shaft are not keyed in position, but are locked one with the other by dog jaws, the first one being locked in a similar manner to a solid flange on the shaft through teeth cut in it. Generous ball bearings and a large inspection cover in the top of the case are other features worthy of notice.

Force-screws for Flanges.

A universal joint at each end of the propeller shaft then takes the drive to the worm, which is mounted over the back axle. The worm housing accommodates the worm and its bearings, as well as its self-contained thrust ball races, in such a way that the whole of the moving parts can be withdrawn endwise after the removal of the . necessary covers. With regard to this last, further evidence of careful thought in respect of its design is the fact that force-screw holes are provided in the flat flange covers, thus avoiding the possibility of a careless mechanic, engaged in dissembling this component, attempting to remove an obstinate cover with the use of a chisel and so damaging the faces for further use.

All the road wheels run on plain floating bearings : our illustration of the back wheel (of cast steel, by the way) shows that the hub cap is of special design, and serves to lock the wheel in position around and over the floating bushes. The worm wheel itself, with its necessary ball bearings, can be remok ed en bloc with the worm if necessary, after the caps holding the main bearings have been unbolted. The withdrawal of the differential shafts then permits the whole of this part of the mechanism to be liftedbodily out of the top of the case, the worm housing being bolted to the main easing by a large flange, as shown in our illustrations.

Sensible Brake Installation.

With regard to the brakes, here again is much evidence of knowledge of the subject of the conditions under which the machine will have to be operated. A point for which we have always contended has been embodied by Mr. McCurd. We have always insisted that it is best to tempt a driver to use the brake which would be used as a rule under ordinary conditions. For that reason, we have argued that the brake pedal should be connected to a brake on the back wheels, and not to the countershaft brake ; this has been effected on the McCurd 3,-ton model. The hand-brake lever, which is of the pull-up type, controls the powerful countershaft brake, situated just behind the gearbox in the usual position. In addition to these two, there is an emergency brake mounted on the framing holding the petrol tank ; this controls yet

another brake concentric with the pedal-operated brake on each of the hind wheels.In order to balance the area available for braking purposes on the two back wheel brakes, the inner one is much wider than the outer one, We consider that this concentric arrangement, in the case of two backwheel brakes, is better than one in which the two brakes are placed side by side ; there is less risk of an overheated one of the pair destroying the efficiency of its neighbour. The back axle is controlled

The hind wheel and its special hub.

in movement by a pressed-steel torque bar, and by two tubular radius rods carried w ell forward.

Striking Gear in a Separate Box.

With regard to the control, the engine levers are situated just above the steering wheel in a convenient position. The throttle control on the dashboard can he varied by a small over-riding pedal. The gear change is of unusual gate design, although such a

method has been used before, in order to reduce the lateral travel at the top end of the gate lever, the latter is made to rock about the quadrant, the gate being placed below. The striking gear, which is of unique design, and has several interesting features, is carried in a separate box attached to a forward cross member.

No Grease To Get Hard.

We have said before that Mr. McCurd has set to work to tempt the driver to do the right thing— notably in the matter of brakes. Only in emergency, in this last respect, will he operate the countershaft brake, and so heavily stress the final drive. Ile has always felt, he tells us, that, so far as he has noticed, practically no spring pins are properly lubricated, although all sorts of ingenious devices have been embodied from time to time to effect that end. They have failed in many cases because the driver has not been tempted to operate them periodically. Sound knowledge of the dliver is evident in Mr. McCurd's decision to fix little oil boxes and wick feeds to every spring pin. In the writer's own experience, he confesses to a weakness for such boxes, and to a tendency constantly to be going round them at odd off times with an oil can, ensuring that they have their proper supply of lubricant.

We Must See How It Runs.

In conclusion we may record our opinion of-the new model described above as favourable. We shall hope to test its load capabilities and other characteristics and to watch its ability to resist wear and tear as time goes on. The machine is likely to find early buyers.