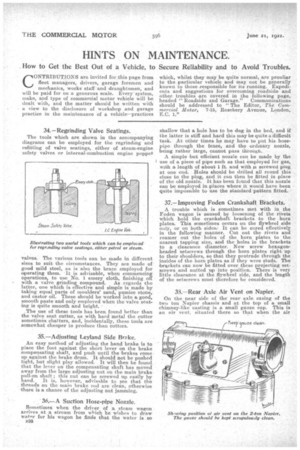

34.—Regrinding Valve Seatings.

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

The tools which are shown in the accompanying diagrams can be employed for the regrinding and refitting of valve seatings, either of steam-engine safety valves or internal-combustion engine poppet.

valves. The various tools can be made in different sizes to suit the circumstances. They are made of good mild steel, as is also the brace employed for operating them. It is advisable, when commencing operations, to use N. 1 emery. cloth, finishing off with a valve grinding compound. As regards the latter, one which is effective and simple is made by taking equal parts of moulders' sand, pumice stone, and castor oil. These should be worked into a good, smooth paste and only employed when the valve seating is quite smooth and bright. • The use of these tools has been found better than the valve seat cutter, as with hard metal the cutter sometimes chatters, and, incidentally, these tools are somewhat cheaper to produce than cutters.

35.—Adjusting Leyland Side Brake. An easy method of adjusting the hand brake is to place the foot against the short lever on the brake compensating shaft, and push until the brakes come up against the brake drum. It should not be pushed tight, but slight play allowed. It will then be founcl that the Iever on the compensating shaft has moved away from the large adjusting nut on the main brake pull-on shaft ; this nut can be screwed up easily by hand. It is, however, advisable to ee that the threads on the main brake rod are clean, otherwise -there is a chance of the adjusting nut jamming.

36.--A Suction Hose-pipe Nozzle. Sometimes when the driver of a, steam wagon arrives at a stream from which he wishes to draw water for his wagon he finds that the water is so shallow that a hole has to be dug in the bed, and if the latter is stiff and hard this may be quite a difficult task. At other times he may have to put his hosepipe through the fence, and the ordinary nozzle, being rather large, cannot pass through. A simple but efficient nozzle can be made by the use of a piece of pipe such as that employed for gas, with a length of about 1 ft. and with la screwed plug at one end. Holes should be drilled all round this close to the plug, and it can then be fitted in place of the old nozzle. It has been found that this nozzle can be employed in places where it would have been quite impossible to use the standard pattern fitted.

37.—Improving Foden Crankshaft Brackets.

A trouble which is sometimes met with in the Foden wagon is caused by loosening of the rivets which hold the crankshaft brackets to the horn plates. This sometimes occurs on the flywheel side only, or on both sides: It can be cured effectively in the following manner. Cut out the rivets and reamer out the holes of the horn plates to the nearest tapping size, and the holes in the brackets to a clearance diameter. Now screw hexagonheaded setscrews through the horn plates right up to their shoulders, so that they protrude through the insides of the horn plates as if they were Studs. The brackets can now be fitted over these projecting set. screws and nutted up into position. There is very little clearance at the flywheel side, and the length of the setscrews must therefore be considered.

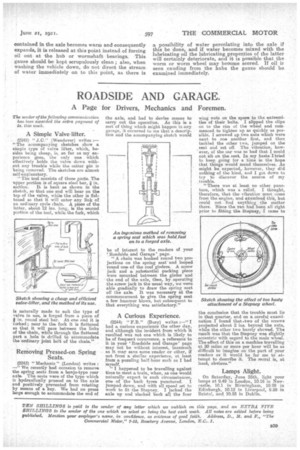

33.—Rear Axle Air Vent on Napier.

On the near side of the rear axle casing of the two ton Napier chassis and at the top of a small chimney-like casting is a small gauze cap. This is an air vent, situated there so that when the air contained in the axle becomes warm and consequently expands, it is released at this point instead of forcing oil out at -the hub or worrashaft bearings. This . gauze should be kept scrupulously clean ; also, when washing the vehicle down, do not direct the stream of water immediately on to this point, as there is a possibility of water percolating into the axle if this be done, and if water becomes mixed with the lubricating oil the lubricating properties of the latter will certainly deteriorate, and it is possible that the worm or worm wheel may become scored, If oil is seen exuding from the hubs the gauze should be examined immediately.