HEAVY HAULAGE ECONOFREIGHT

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

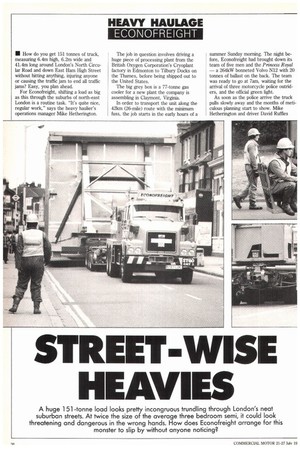

• How do you get 151 tonnes of truck, measuring 6.4m high, 6.2m wide and 41.4m long around London's North Circular Road and down East Ham High Street without hitting anything, injuring anyone or causing the traffic jam to end all traffic jams? Easy, you plan ahead.

For Econofreight, shifting a load as big as this through the suburbs of north-east London is a routine task. "It's quite nice, regular work," says the heavy haulier's operations manager Mike Hetherington. The job in question involves driving a huge piece of processing plant from the British Oxygen Corporation's Cryoplant factory in Edmonton to Tilbury Docks on the Thames, before being shipped out to the United States.

The big grey box is a 77-tonne gas cooler for a new plant the company is assembling in Claymont, Virginia.

In order to transport the unit along the 42km (26-mile) route with the minimum fuss, the job starts in the early hours of a

summer Sunday morning. The night before, Econofreight had brought down its team of five men and the Princess Royal — a 264kW bonneted Volvo N12 with 20 tonnes of ballast on the back. The team was ready to go at 7am, waiting for the arrival of three motorcycle police outriders, and the official green light.

As soon as the police arrive the truck pulls slowly away and the months of meticulous planning start to show. Mike Hetherington and driver David Ruffles have a carefully plotted route to follow and as soon as we have rolled out onto the A406 Angel Road on the North Circular we hit the first problems of the day — traffic lights, a bridge and then a roundabout. Crawling along at four or five kilometres per hour, the truck takes the centre of the road as we go over the Lea Valley viaduct.

When we reach the dual-carriageway section of the North Circular on the fringes of Epping Forest, Econofreight has decided to drive along the opposite carriageway in contraflow, to help it squeeze under a footbridge. One of the team runs ahead to stand on the bridge and check that the top of the load will travel beneath. It is a close shave.

Leaving the North Circular we travel south through Epping Forest on the A104 Woodford New Road. There is a cattle grid to be crossed and, says Hetherington, it is a good job the grid has been strenghthened in recent years. Econo Left and below: Rear bogie trailerman keeps an eye out from the back.

Bottom: Easy does it. . . even with an experienced learn, heavy haulage is never dull — particularly when moving such a bulky load through city streets. freight used to have to lay reinforcing plates over the grid before driving across.

When the route was planned, Econofreight noted that "the bollards at the junction of Whipps Cross Road and Preston Road may have to be removed." On the day, we squeeze through — slowly.

Towards the end of Whipps Cross Road. comes the next, completely invisible hazard: the London Underground tube line which runs beneath the road connecting Leytonstone to Snaresbrook. Ruffles carefully takes the centre of the road as planned and the truck rolls on through to negotiate the Green Man roundabout.

PRINCESS ROYAL

Because the next road junction will involve turning almost back on ourselves at a right fork, where the Al2 Cambridge Park meets the A1008 Blake Hall Road, Econofreight has opted to reverse all the way up Cambridge Park. Ruffles puffs out his cheeks and puts the Princess Royal into a reverse crawl. The rest of the team walk alongside the truck, to help smooth its passage. We have been on the road now for about two hours and somebody, usually Hetherington, has been walking alongside or in front of the truck all of the way.

We have also collected at least two police cars along the way too, to add to our growing team of minders. Before long we will be joined by a London Transport Police team and their car and turn into a long, slow-moving procession.

When the reversing truck finally reaches the Al2/A1000 junction, it reverses straight past, pauses to dunk back into forward and trundles south again. Hetherington jumps up on to a small seat between the back of the cab and the ballast box for a rest.

The roads start getting narrower, the Sunday morning traffic thicker and the drive more "interesting", says a smiling Hetherington. We reach the hump-backed Victorian railway bridge at Manor Park.

Econofreight has laid down in the route instructions that "the tractor must be reversed and a 16-feet (4.87m) long drawbar used". The scene is also complicated by a gang of five navvies digging a trench along the run-up to the bridge and a zebra crossing on its crest. We take it slowly, the police get the trench diggers to hold fire and fill in a bit of the excavation they have already opened up.

We are not popular. The local London borough has taken down the bollards which usually sit on the crest of the bridge and the trailer literally inches over the bridge. Trailerman Gary Porter lies down on his stomach on the road surface to make sure that the trailer does not bottom on the bridge. He can alter the height and position of the trailer from his seat at the rear of the unit by throwing series of hydraulic switches. The four axles of the rear bogie can also be indepen

dently steered by Porter with the same set of hydraulic levers.

We drive due south down the ever narrowing A117 East Ham High Street, over another London Underground tube line. We pass a crowd celebrating what looked like a religious festival day, choking the streets. They hardly seemed to notice us.

When we meet the A13 dual carriageway where everyone expected us to turn left and head for Tilbury Docks, we slither under the flyover bridge and pull in for lunch, After diving into the BOC Transit van to grab a sandwich and a pork pie, everyone gathers for a team photograph.

After lunch it is right onto the A13 dual carriageway to head east. At the King Edward Road footbridge we take the opposite side of the road again and drive contraflow. This helps us turn right off the A13 onto River Road in Barking, where the truck heads south towards the river bank. "Apply standard caution when crossing the main sewer in River Road," says the plan, "for approximately lkm southbound. Thames Water asks that the haulier confirms that the conditions of standard caution will be strictly adhered to in all cases."

It is a similar story as we pass over a whole series of sewers after rejoining the A13. At the Dartford Tunnel interchange we have to reduce the height of the truck to its absolute minimum to negotiate the roundabout. On the B149 Wood View stretch of the route the crash barriers have had to be removed and Hetherington heaps praise on the local London boroughs. He comments that they are always helpful, and thorough in helping the haulier plan the safest route.

MIRACULOUSLY REPLACED

When we retrace the route later in the day, bollards, traffic islands and beacons, which had all been removed for us to pass by, have all been miraculously replaced with speed and efficiency.

We carry out some more contraflow manoeuvres and enter Tilbury Docks via the A1089 St Andrew's Road entrance. The route instructions are clear: "No other vehicle must be on the bridge at the approach to the docks at the same time."

The BOC load was only a 156 tonne relative tiddler for Econofreight, but it still needed careful planning and great attention to detail.

The haulier often plans things months, if not years, ahead. Clients will frequently call in Econofreight before the load has even been designed to ask whether any special transportation features should be built in from the start. Locking positions and overall dimensions have to be carefully considered.

After all, it is no good building an ocean racing yacht in your back yard only to find that you cannot get it out down the street. . .

'Air suspension is set to replace the mechanical set-up as the nation's most popular suspension over the next few years: That's not Mercedes talking. 'Truck' magazine said that, way back in December 1987. And it's no sweeping statement.

A look at the trailer market alone shows why. Two years ago, only 50/0 of 3-axle trailers were built with air suspension. Today, over 30% have it. Increasingly, the benefits are being recognised by operators and customers alike.

Particularly those who transport brittle foodstuffs like crisps and other fragile loads.

For such people, the attractions are obvious.

The chief buyer at a large bottling plant recently told journalists how he could spot which bottles had arrived on air suspension: they had fewer scratches From rubbing against each other.