New Semi-automatic Gearbox in Leyland Chassis

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

Semi-automatic Transmission, Using Direct Air Operation to a Wilson Epicyclic Gearbox, is now Available in Leyland Passenger Chassis : A Device to Prevent Run-back on Hills is Incorporated

DIRECT air-operated semi-automatic epicyclic gearbox and its conhave, been developed jointly, under son and Leyland patents, by Self nging Gears, Ltd., and Leyland ors, Ltd. The new control, which fitted to the Atkinson Alpha chassis :ribed in The Commercial Motor November 6, is to be termed the umo-cyclic gearbox and 168 Leychassis with this unit have been :red for operation in Palestine, icht, Copenhagen, Pretoria and iterdam.

earboxes of this type have already t supplied in chassis to these opera The Tiger Cub with Saunders lightweight body being tried by don Transport is equipped with the nno-cyclic gearbox. It has also L tested in double-decker service, ae conventional clutch or gear .gement pedal is not required; use upon moving the gear lever ugh the gate to any set position, Lir valve is opened to one of five 'tiers in the Wilson-type gearbox this in turn automatically applies yrake band of an epicyclic train.

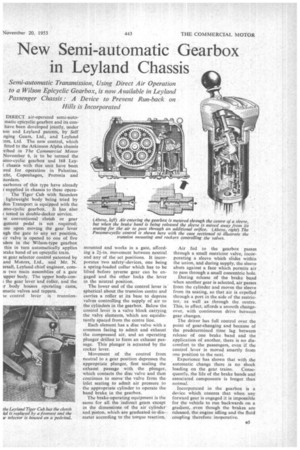

le gear selector control patented by and Motors, Ltd., and Mr. N. ersall, Leyland chief engineer, corn:s two main assemblies of a gate upper body. The upper body-conL the gear lever and roller, and the :r body houses operating cams, imatic valves and tappets.

le control lever is trunnion

mounted and works in a gate, affording a 21-in, movement between neutral and any of the set positions. It incorporates two safety,devices, one being a spring-loaded collar which has to be lifted before reverse gear can be engaged and the other locks the lever in the neutral position.

The lower end of the control lever is' spherical about the trunnion centre and carries a roller at its base to depress valves controlling the supply of air to the cylinders in the gearbox. Below the control lever is a valve block carrying the valve elements, which are equidistantly spaced from the centre line.

Each element has a disc valve with a common facing to admit and exhaust the compressed air, and an operating plunger drilled to form an exhaust passage. This plunger is actuated by the rocker lever.

Movement of the control from neutral to a gear position depresses the appropriate plunger, first sealing the exhaust passa_ge with the plunger, which contacts the disc valve and then continues to move the valve from the inlet seating to admit air pressure to the appropriate cylinder to operate the band brake in the gearbox.

The brake-operating equipment is the same for all the indirect gears except in the dimensions of the air cylinder and piston, which are graduated in diameter according to the torque reaction. Air fed to the gearbox passes through a small restrictor valve, incorporating a sleeve which slides within the union, and during supply, the sleeve abuts against a face which permits air _ to pass through a small concentric hole.

During release of the brake band when another gear is selected, air passes from the cylinder and moves the sleeve from its seating, so that air is expelled through a port in the side of the restrictar, as well as ;through the centre. This, in effect, affords a smooth changeover, with continuous drive between gear changes.

The driver has full control over the point of gear-changing and because of the predetermined time lag between release of one brake band and the application of another, there is no discomfort to the passengers, even if the control lever is moved smartly from one position to the next.

Experience has shown that with the automatic change there is no shock

loading on the gear trains. Consequently, the life of the brake bands and associated components is longer than normal.

Incorporated in the gearbox is a device which ensures that when any forward gear is engaged it is impossible for the vehicle to run backwards on a gradient, even though the brakes are released, the engine idling and the fluid coupling therefore inoperative.