HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

593.—Curing Sluggish Safety Valves.

After a steam wagon has been in use for some time, the safety valve or valves are apt to become sluggish and their accuracy cannot always be relied

upon. A good driver always likes to have the valves " alive " at 200 lb. pressure, and this can easily be done if the driver will carry out the following instructions, which are chiefly applicable to the safety valve used on the Paden.

First, remove the valves and into the seats push pieces of wood or lead. Mark the centres of these most accurately and measure the distance between the two centres. This distance (A) must be marked off on the holding-down arm. The lips on these, which come into contact with the valves, should now be filed down until the bearing surface of each is * in. diameter. The valves should also be cleaned and reground, using powdered pumice stone and oil. The jaw which is coupled to the holding-down arm must be free, the pin being tight in the jaw, but a free• fit in the centre hole.

A very important point to-watch is that the stem of the jaw does not touch the casting and this is a point which is sometimes overlooked by repair men.

If there be holes or indentures in the tops of the valves, these may be filled with hard solder or a thin brass washer soldered over each.

594.—Frost Precautions Which Should be Taken on Steam Wagons.

At this time of the year serious defects in steam wagons may be caused through frost, unless proper precautions be taken. In seine cases these precautions are carried almost to excess, with the result that the driver gpends unnecessary time in uncoupling pipes, etc., which can safely be left in situ.

The following remarks, which apply to all makes of overtype steam wagon, describe what is actually necessary to prevent trouble with burst pipes, etc., through frost.

If a wagon be run in for the night and is likely to be at work again the next Morning, it is advisable to bank up the fire and drop the damper. This will keep all parts near the_ boiler and firebox shielded from the frost, but there are other parts which should receive attention nightly.

(I) Run the water out of the filter box ; this will B44 also automatically drain the suction pipes to the pump and injector. (2) Take out the suction. valve of the water feed pump.

. (3) Open the water regulator of the injector. When the wagon has been laid up for some time, say, a long week-end, and frost is possible, it is necessary, in addition to these points, to pay attention to the following. Empty the water tank, remove the boiler wash-out plug to empty the boiler, turn all steam valves to the open position, take off the pipe leading from the water heater to the boiler, uncouple the siphon pipe of the steam gauge and empty out any water it contains. Remove the delivery valve of the water feed pump and, finally, open the drain tap on the emergency lubricator.

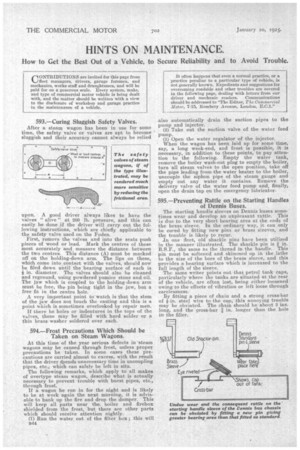

595.—Preventing Rattle on the. Starting Handles of Dennis Buses.

The starting handle sleeves on Dennis buses sometimes wear and develop an unpleasant rattle. This is due to the very short bearing area at the ends of the brass sleeve. In the ordinary way, it can only be cured by fitting new pins or brass sleeves, and the trouble is likely to recur.

.In one fleet, old shackle pins have been utilized in the manner illustrated. The shackle pin is ft in. B.S.F., the same as the thread in the handle. This pin must be softened and skimmed up in the lathe to the size of the bore of the brass sleeve, and this provides a bearing surface which is increased to the full length of the sleeve.

The same writer points out that petrol tank caps, particularly where the tanks are situated at the rear of the vehicle, are often lost, being either loosened owing to the effects of vibration or left loose through carelessness. •

By fitting a piece of chain and a strong cross-bar of i-in. steel wire to the cap, this annoying trouble may be obviated. The chain should be about 3 ins. long, and the cross-bar in. longer than the hole in the filler.