y ou have only to look back a few years to

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

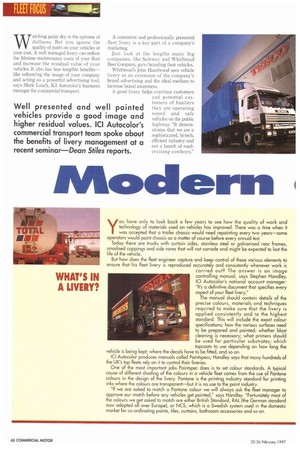

see how the quality of work and technology of materials used on vehicles has improved. There was a time when it was accepted that a trailer chassis would need repainting every two years—some operators would paint chassis as a matter of course before every annual test.

Today there are trucks with curtain sides, stainless steel or galvanised rear frames, anodised cappings and side raves that will not corrode and might be expected to last the life of the vehicle.

But how does the fleet engineer capture and keep control of these various elements to ensure that his fleet livery is reproduced accurately and consistently whenever work is carried out? The answer is an image controlling manual, says Stephen Handley, ICI Autocolor's national account manager: "It's a definitive document that specifies every aspect of your fleet livery."

The manual should contain details of the precise colours, materials and techniques required to make sure that the livery is applied consistently and to the highest standard. This will include the exact colour specifications; how the various surfaces need to be prepared and painted; whether blast cleaning is necessary; what primers should be used for particular substrates; which topcoats to use depending on how long the vehicle is being kept; where the decals have to be fitted, and so on.

ICI Autocolor produces manuals called Paintspecs; Handley says that many hundreds of the UK's top fleets rely on it to control their liveries.

One of the most important jobs Paintspec does is to set colour standards. A typical cause of different shading of the colours in a vehicle fleet comes from the use of Pantone colours in the design of the livery. Pantone is the printing industry standard for printing inks where the colours are transparent—but it is no use to the paint industry. "If we are asked to match a Pantone colour we will always ask the fleet manager to approve our match before any vehicles get painted," says Handley. "Fortunately most of the colours we get asked to match are either British Standard, RAL (the German standard now adopted all over Europe), or NCS, which is a Swedish system used in the domestic market for co-ordinating paints, tiles, curtains, bathroom accessories and so on. "We hove something like 30,000 colours on record," he adds, "all of which have originated from these various sources. And as with Pantone we ask our fleet customers to sign off each one before approving it as a colour 'standard. These colour 'standards' are produced by spraying panels with two-pack paint which is colour fast for a long time if stored correctly.

"We store our colour standards at Stowmarket, which is our main paints plant in Suffolk," says Handley "Some of the original panels stored -have not changed at all since the first day they were sprayed some 15 years ago. We even have colour standards that go back to the 1930s...and some even older than that, dating back from the time when Henry Ford told us that we could have any colour—as long as it was black!"