SLAPLESS ALUMINIUM PISTONS.

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

ONE of the greatest difficulties facing the designer and maker of aluminium and aluminium-alloy pistons is how to reduce the slap which so often occurs before an engine, equipped with such pistons, warms up to its work.

The difficulty is due to the unequal coefficients of expansion of the cast-iron of the cylinders and the alloy of the pistons. Certain alloys have been produced which do much to reduce the difference between the coefficients, but there is still another form of piston in which better fitting of the piston at all temperatures is achieved, and this form of piston presents the advantage that it can give sufficiently to prevent binding due to cylinder distortion, which in some engines is considerably more than the usual clearance allowed between the cylinder and piston.

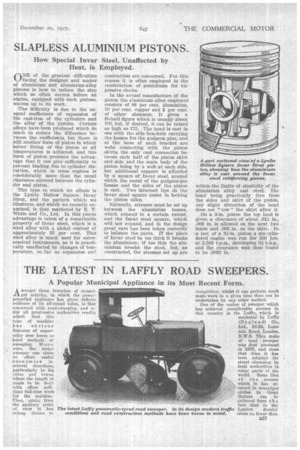

The type to which we allude is the Lynite Hollow Square Invar Strut, and the pattern which we illustrate, and which we recently examined, is that marketed by E. T. White and Co., Ltd. In this piston advantage is taken of a remarkable property of Invar steel, which is a steel alloy with a nickel content of approximately 35 per cent. This steel alloy is much used for astronomical instruments, as it is practically unaffected by changes of temperature, so far as expansion atill

contraction are concerned. For this reason it is often employed in the construction of pendulums for 'expensive clocks.

In the actual manufacture of the piston the aluminium alloy employed consists of 88 per cent. aluminium, 10 per cent. copper and 2 per cent. of other elements. It gives a Brinell figure which is usually about 105, but, if desired, it can be raised as high as 175. The head is cast in one with the side brackets carrying the bosses for the gudgeon pins, and at the base of each bracket are webs connecting with the piston skirts, the only cast connection between each half of the piston skirt and side and the main body of the piston being by a we at each side, but additional support is afforded by a square of Invar steel, around which the metal of the gudgeon-pin bosses and the sides of the piston is cast. Two inturned lips on the Invar steel square assist in locking the piston sides.

Naturally, stresses must be set up between the aluminium bosses, which expand to a certain extent, and the Ityvar steel square, which will not expand, and in the design great care has been taken correctly to balance the parts. a the piece of Inver steel be too thick it breaks the aluminium ; if too thin the aluminium breaks the steel, but, as constructed, the stresses set up are

within -the limits of elasticity of the aluminium alloy and steel. The head being practically free from the sides and skirt of the piston, any slight distortion of the head does not " tow " the skirt after it.

On a 3-in, piston the top land is given a clearance of about .012 in., .009 in. is allowed on the next two lands and .002 in. on the skirl. In -a test of a 31-in, piston a six-cylindered engine was run for 500 hrs. at 2,500 r.p.m., developing 54 b.h.p., and the clearance was then found to be .0026 in.