A New Rotary Refuse Collector

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

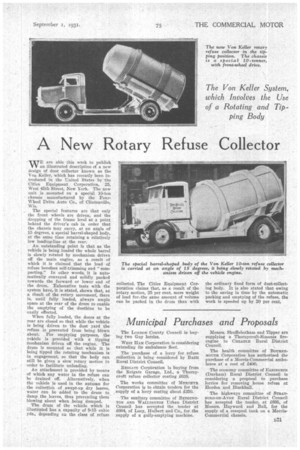

The Von Keller System, which Involves the Use of a Rotating and Tipping Body

WE are able this week to publish an illustrated description c. a new design of dust collector known as the Von Keller, which has recently been introduced in the United States by the Cities Equipment Corporation, 25, West 45th Street, l'sTew York. The new unit is mounted on a special 10-ton chassis manufactured by the FourWheel Drive Auto Co., of Clintonville, Wis.

The special features are that only the front wheels are driven, and the dropping of the frame level at a point behind the driver's cab in order that the chassis may carry, at an angle of 15 degrees, a special barrel-shaped body, at the same time retaining a relatively low loading-line at the rear.

An. outstanding point is that as the vehicle is being loaded the whole barrel is slowly rotated by mechanism driven off the main engine, as a result of which it is claimed that the load of refuse becoines self-trimming and "compacting." In other words it is automatically conveyed and solidly packed towards the forward or lower end of the drum. Exhaustive tests with the system have, it is stated, shown that, as a result of the rotary movement', there is, until fully loaded, always ample space at the rear of the drum to enable the emptying of the dustbins to be easily effected.

When fully loaded, the doors at the rear are closed so that while the vehicle is being driven to the dust yard the refuse is prevented from being blown about. For emptying purposes, the vehicle is provided with a tipping mechanism driven off the engine. The drum is mounted so that while it is being tipped the rotating mechanism is in engagement, so that the body can still be given a slow rotary motion in order to facilitate unloading.

An attachment is provided by means of which any water in the refuse can be drained off. Alternatively, when the vehicle is used in the autumn for the collectiois of swept-up dry leaves, water can be added to the drum to damp the leaves, thus preventing them blowing about when being dumped.

The drum of the vehicle which is illustrated has a capacity of 9-15 cubic yds., depending on the class of refuse collected. The Cities Equipment Corporation claims that, as a result of the rotary motion, 25 per cent, more weight of load for-the same amount of volume can be packed in the drum than with the ordinary fixed form of dust-collecting body. It is also stated that owing to the saving in time by the automatic packing and emptying of the refuse, the work is speeded up by 20 per cent.