Strong exports boost Sweden

Page 61

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Sweden has two of the strongest manufacturers in Europe-but Scandinavia and the Low Countries all boast powerful vehicle exporters. Reporif by Graham Montgomerie

1E SCANDINAVIAN and BeneK countries boast some of the ggest names in the commer31 vehicle industry — Scania, Avo and DAF.

But there is more to it than at. Belgium is the European .adquarters of International irvester and also the home of in Hool and Jonkheere.

In this CM survey, I have .en looking at these countries

d in particular at their cornercial vehicle involvement. According to the Swedish Initute, Sweden is the most otorised country in Europe. Jung 1975, the country ached a density of one car per ree inhabitants: a figure .ceeded by the USA, Canada, Jstralia and New Zealand. In )77, the number of commeral vehicles had risen to 32,000.

Vigorous expansion in the 3St 10 years has made the Nedish motor industry one of e country's leading industries. ehicle production and its fated industries currently -nploy 10 per cent of the orking population of Sweden, ith the two large-scale domes:producers being Saab-Scania id Volvo.

Like many of the world's )mmercial vehicle companies, cania is merely one part of a rge engineering conglomerate ihich is divided into four main actions: Scania (Commercial ehicles), Saab (cars), the arospace division and the Norarmatur division. The product 3nge thus includes trucks, uses, diesel engines, cars, ircraft, guided missiles and vionics, industrial equipment, ietering systems, medical proucts and military training quipment.

The part we are interested in Scania — is the largest unit in -le Saab-Scania combine and is asponsible for the development nd manufacture of industrial nd marine diesel engines as /ell as the familiar trucks and ,uses.

Last year, the worldwide total ales of Scania vehicles was ,200 — a total made up of 9,200 lorries and 2000 buses. ;ales of industrial and marine ingines amounted to over i100. Again in 1978, the inancial contribution from the ;cania division was over 6.1 housand million Kroner around £680m) out of a group otal of around 11.6 thousand nillion Kroner.

The total number of imployees of Saab-Scania is 1-0,000, of whom 9000 work werseas. Scania accounts for iround 19,000 of the total, with about 6500 at the main plant at Sodertalje near Stockholm and 5500 in countries outside Sweden. Although the company's main markets are still Scandinavia and the EEC, Scania is at present represented in 80 export markets throughout the world, with about 86 per cent of the vehicles produced in 1978 going to customers outside Sweden.

The history of Scania goes back a long way in automotive engineering terms. In 1891 Vagrifabriksaktiebolaget i Sodertalje was established as an assembly factory for railway carriages. More commonly known as Vabis, the company went on to produce Sweden's first factory-built car and then turned to trucks in 1903.

In 1911, Vabis merged with Maskinfabriks Aktiebolaget Scania in Malmo to become Scania-Vabis. In the same year, the first bus built on a special chassis was presented. From 1924, production was concentrated on heavy vehicles, with the last car being delivered at the end of the 1920s.

Scania has many production facilities both at home ahd abroad. In Sweden, there are seven factories around the country, with the Scania-Bussar subsidiary located in central Sweden. This company is res ponsible for the desigr manufacture and marketing ( complete buses and bL chassis.

The company is very we represented in South Americi with factories in both Brazil an Argentina. Scania in fact starte in Brazil as long ago as 195 and last year delivered 480 trucks and buses from the SE Paulo factory.

Scania's share of the Brazi ian market has increased apac( During 1977, for example, tlcompany supplied 40 per cer of the heavy lorries sold i Brazil. Saab-Scania Argentir SA started production in 197 at Tucuman in the North West the country. Around 40 vehicles were produced i 1978.

Other Scania assemb plants are located in Iraq ar Tanzania, while another is cL rently under construction Morocco. On the other side the world, the assembly Scania trucks in Australia begs in 1977 from semi-knock-dovi kits (SKD), the components f which are shipped direct fro Sweden to Australia. To dat some 800 Scanias are in oper tion on this continent.

Scania also has a manufa turing facility at Zwolle in Hi land, about 100km (62 mil( east of Amsterdam. The Dut+ organisation — Scania Ned( land BV — is especially impo ant as it is also responsible f marketing Scania produc within the original EEC cou tries, ie Holland, Luxembour Belgium, France, Italy and W( Germany. The first Scar chassis was shipped to Holla in 1946, since when ov 17,500 lorries have been sol( In Sweden itself, Scania held the franchise for Vol wagen products since 194 with over 800,000 VWs bei sold in Sweden since that da The present company, Svens. Volkswagen AB, was formed 1 969 as' a wholly owned subsidiary to market VW, Audi and Porsche.

The Oskarshamn works is the second largest in the Scania division and employs around 1250 people. Established in 1946, when it was known as Be-Ge Karosserifabrik, the company was bought by ScaniaVabis in 1966 when its name was changed to Scania-Hytter AB. Since that date, production of Scania cabs has taken place there.

At Lulea, the output consists mainly of chassis frame members, bumpers and rear axle casings. To give an idea of the Lulea capability, the factory has an annual capacity of about 32,000 rear axle casings and 18,000 chassis side-members.

The psv side of Saab-Scania is handled by Scania-Bussar from Katrineholm. This particular branch of the organisation is responsible for the design, manufacture and sales of all Scania buses marketed in Sweden and abroad, an arrangement which was previously centred on Sodertalje before being transferred to Katrineholm.

The company was formed as a result of "the greatest event in the history of Swedish road traffic-. I am referring, of course, to the complete changeover from driving on the left, as in the UK, to driving on the right, which literally took place overnight on September 3, 1967. No less than half the 7,000 buses operating iri Sweden at that time had to be replaced, as just one of the many aspects involved in the change-over. The remainder required extensive conversion to adapt them to the new order.

A considerable fall-off in demand for buses was anticipated after the changeover, which was when the then Scania-Vabis company decided to acquire one of the country's leading coach-. builders, Svenska Karosseri Verkstaderna, Katrineholm. This had a dual purpose: it released space and manpower at "head office" in Sodert5lje and it improved the employment situation in Katrineholm.

Both Scania and Volvo make a higher proportion of components "in house" than most of their European rivals, including engines, gearboxes and axles. But the similarity does not end there. Both factories use fully synchromesh gearboxes, show a great deal of enthusiasm for turbocharged engines and indicate the capacity of the power unit with its type number.

Thus the D8 (naturally aspirated) and DS8 (turbocharged) have a capacity of nearly eight litres. Both are inline six-cylinder units producing 120kW (161bhp) and 153kW (205bhp) respectively. These are the power units found in the 81 and 86 ranges from Scania.

Moving up the weight scale, we come to the 111 models which use the DS11 engine again a six-cylinder unit but with no naturally aspirated version. From its 11-litre (671 cuin) swept volume, the DS11 develops 206kW (275bhp) at 220Orpm.

At the top end of the Scania range, the engine is of V8 configuration with a capacity of 14 litres (854 cuin), turbocharged to produce 276kW (370bhp). The torque output is equally impressive at 1,480Nm (1,090 lbft).

Two basic gearboxes cover the truck range, from the 0760 five-speed unit at the lower end to the GR 860 ten-speed rangechange for the 141/146 models. In the middle of the range, the GS760 is used, which is the G760 with the addition of a splitter.

1977 was a year for jubilees. Apart from our own royal one, the year also represented the 50th anniversary of Volvo. The first truck was built in 1928 not long after the first Volvo car christened Jakob rolled out of the Gothenburg factory in 1927.

This first Volvo lorry, the LV40, was powered by the car engine, a four-cylinder sidevalve unit with an output of 21kW (28bhp) at 2000rpm. The payload capacity was around 11/2 tons. Compare this with a 50-ton F12 with 300plus horsepower: such is progress.

The Volvo Group, the largest industrial enterprise in the Nordic area, had a turnover of approximately 16,100 Skr (about £1 ,790m) during 1977. Within the corporate structure, the products are subdivided into

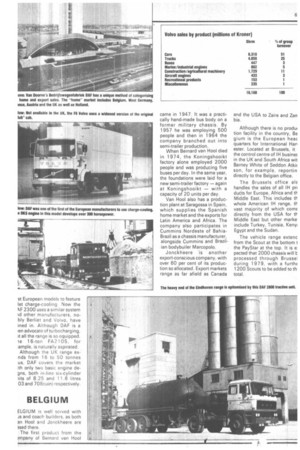

seven groups whose percenta contribution is shown in t accompanying table.

Cars are responsible for co 50 per cent of the Volvo grout turnover with the 240 a 260-Series as well as the and 343 models, formerly ma by OAF and fitted with t unique continuously variat trasnmission.

The Volvo truck division t came an independent part of t Volvo group in 1969 and is ci rently responsible for more th, 25 per cent of the group tui over. During the past 10 yea, Volvo has climbed from 15 position on the ladder of hea truck manufacturers in Eurol to sixth. Last year about 24,2C lorries and 2000 light cros country vehicles were pr duced.• • • Buses also contribute to tl total product range. Vol, manufactures four chassis typ with the possibility of usir bodywork to suit local needs. Marine and industrial enines are made by Volvo Penta. he range includes the Aquaiatic range of inboard engines tith outboard drives. These ave now been supplemented tith outboard engines so Volvo 'enta can now offer a marine ngine programme with a wide ange of application.

Through its sales of contruction, forestry and agriculural machinery, Volvo BM is esponsible for about 11 per :ent of the total turnover. The :onstruction machine proiramme includes loaders, Jumpers, road graders, mobile :ranes and excavators with :ombine harvesters and farm ractors being covered by the igricultural division. The orestry programme includes nachinery for felling, deimbing, cross-cutting, sorting )nd transport.

Aircraft jet engines for the Swedish Air Force take up most of the production capacity of Volvo Flygmotor but this section of Volvo activity also includes the production of hydraulic machinery for civilian installations.

Volvo has recently branched out into the recreational sector with Jofa, a company which builds and markets boats and sports equipment.

Export has always been a Volvo strong point — indeed a necessity in view of the size of the domestic market — with around 80 per cent of commercial vehicle production being earmarked for export to around 70 countries throughout the world. This compares with the 24 chassis exported in 19281

The UK is by far the largest and most successful market for Volvo, accounting for about 17 per cent of total sales. About 4,200 Volvos were sold here last year, an increase of 25 per cent compared with 1977.

The domestic production plants are scattered throughout Sweden, with final chassis production being concentrated at Gothenburg. The factory at Skovde produces engines, brake-drums and drive-shafts. During the early Seventies, capacity at Skitivde was increased to give a production capability of 60,000 engines per year. Within the Sktivde complex, the foundry has been extensively modernised and extended to increase the yearly production from 35,000 to 65,000 tons of finished castings.

Gearboxes are produced at Koping at a rate of 30,000 per year. This factory is also responsible for front and rear-axle assembly. Situated in the far north of Sweden, the cab plant at Umea produces 25,000 cabs annually. Although only three basic designs are produced here, they are built in 50 different versions.

About 50 per cent of Volvo trucks are assembled in Gothenburg. The rest of the production is spread throughout the world in such places as Belgium, Greece, Portugal, Morocco, Mozambique, Iran, Australia, Malaysia, Peru, Uruguay, Kenya and, of course, Irvine in Scotland.

The largest Volvo commercial vehicle unit abroad is in Belgium — Volvo Europa NV. This company carries out the assembly of light trucks (the Club of Four series) at Oostakker near Ghent and heavy trucks in Alsemberg. In Oostakker, there is also a central parts warehouse which mainly supplies the EEC and North America.

Volvo is another European manufacturer which is extremely interested in the potential of the South American market in general, and Brazil in particular. A new factory is being built at Curitiba for the assembly of buses in the early stages with trucks to follow. At full production, the plant is scheduled to make 6,000 chassis per year.

Volvo was a member of the Club of Four consortium with DAF, Saviem and Magirus. This was a joint co-operation exercise for the development and production of a light/medium truck range. But such joint functions have not stopped at commercial vehicles.

On the car side, Volvo is ir volved with Renault an Peugeot in the manufacture ( the V6 engine for the 260 series. Furthermore, Volvo hE an agreement with Claas Germany concerning the joir marketing of combine hap esters. International Harvest( co-operates with Volvo in th development of components -lc farm tractors, Poclain c( operates with Volvo in the ma keting of hydraulic excavators the list goes on.

Since 1973, the comple. Volvo truck range has bee replaced, starting with the troduction of the bonnetted f Series. Aimed mainly at tlconstruction market, the N' N10 and N12 models haN gross weights ranging from 1 to 33 tons, with the tyr number denoting the capacity the engine in litres.

Although only introduced 1973, the N-Series has alrea( received an update with the a nouncement of the TD7OG e gine for the N7. The N12, tl most powerful of the series, nc has a modified 12-lit (732cuin) engine designat( the TD 120E, which features new fuel pump and turb charger combination.

Following the introduction the N-Series came the launch the light F-range in 1975. Tf was the Volvo version of ti Club of Four design and, like t other members of the cons( hum, Volvo now seems anxio to play down the origins of t vehicle. The light F chassis z not available in the U although there are rumours Volvo will launch a 16-ton v sion later this year tailor specifically for this market.

The replacement for t highly successful F88/89 car in 1977 with the introduction the F10 and F12 models. TI launch was followed in t autumn of last year with the and F7. As far as the UK concerned, the F7 replaced long-serving F86, whereas 1 F6 is not available (nor likely be) for this market.

I mentioned earlier that Vo is very successful in the I market. Not surprisingly, t state of affairs applies in Sc dinavia also, although — ag not surprisingly — there is c siderable opposition from Scania. Last year in Scandinavia in the 10-ton-plus weight category, Volvo was the leading make in every country. In Sweden, for example, Volvo has a share of nearly 52 per cent of Volvos registered in Sweden, a figure which has now been equalled by Volvo exports to France. Another market where the Gothenburg company's sales have increased rapidly is the USA, where 800 Volvo trucks were sold last year.

To increase its penetration in America, Volvo has signed an agreement with US truck manufacturer Freightliner (not to be confused with the NFC company of the same name) which gives Volvo access to a network of 200 sales and service points throughout the American continent.

Like most manufacturers. Volvo has had its ups and downs. One very definite "up" was an order signed with China, the main item of which was the delivery of 700 N-Series trucks. This was counterbalanced to a certain extent by the total cessation of sales in Iran due to the political upheaval.

Although overshadowed in Scandinavia by Volvo and Scania, Finnish manufacturer Sisu has been around a long time. In fact it has been producing dumptrucks for nearly 50 years.

The official name of the company is Oy Suomen Autoteollisuus AB and production takes place in three factories located at Helsinki, Hameenlinna and Karjaa. Long-time users of Leyland engines, Sisu currently fits both 410 and 690 power units, as well as engines from RollsRoyce and Cummins.

There was a tentative effort to market the R-149 dumptruck in 6x4 and 6x2 configuration in the UK in 1974, but this came to nothing,

HOLLAND

HOLLAND of course means DAF or, in official terminology, Van Doorne's Bedrijfswagenfabriek DAF By.

The origins of DAF Trucks go back to 1928 when Hub van Doorne started a small light engineering business with his brother Wim. This expanded to produce trailers and semitrailers in the early Thirties and trailer production is still a part of the DAF organisation today.

It was not until 1948 that the decision was made to move into the truck market with series production starting in a new factory in 1950. By 1955, the 10,000th chassis had been produced.

In addition to the trailer factory, the DAF group has a Special Products Division which carries out work not necessarily in the field of commercial vehicles. As an example, in 1 976 the division won a contract for supplying fighter landing gear for several NATO countries.

In 1966 the production of cabs and axles was transferred to a new factory at Oevel, just over the border into Belgium. Again in Belgium, at Ophasselt, DAF has a small foundry.

The financial structure of DAF Trucks is well known mainly because of the much publicised International Harvester involvement and the DAF efforts to emphasise that IH will not get control. Of the total share capital, 42 per cent is in the hands of the Van Doorne holding company. International holds 33 per cent, with the remaining 25 per cent belonging to .DSM, a Dutch stateowned company that originated as a mining concern and now operates throughout the world in the chemical sector.

DAF now has subsidiaries in Belgium, West Germany, Italy, France, Austria and, last but not least, DAF Trucks (GB) Ltd at Marlow, Bucks.

DAF has a unique method of categorising its home and export sales. The company has a European Domestic Division of eight subsidiaries comprising the six mentioned above with the addition of Switzerland and Holland. This group comprises the "homemarket with anything outside these countries being counted as -export". The EDD will account for around 10,500 trucks this year with the export market (the rest of Europe, Africa and the Middle East) taking around 2500.

Although it sounds a contradiction in terms, DAF Trucks produce a wide range of passenger vehicles in chassis form only.They are produced for every application from luxury touring coaches to city buses with a wide spread of designs, including vertical engines, horizontal engines and underfloor engines.

In addition to engines for road vehicles, DAF also builds power units for other applications including generator sets, earth-moving equipment, ships and pleasure craft, to list just a few examples.

DAF's Special Products Division produces a range of trailers and semi-trailers which extends from a light model with two sixtonne axles to a heavy tri-axle trailer for international haulage. The company can also supply drop-frame trailers, tipping trailers, and special models for demountable bodies. At the top of the DAF range is the Eurotrailer which is a frameless aluminium box-van.

Another product of the

Special Products Division is ti terminal tractor. This vehicl which uses many standard tru components, has a one man ti cab, automatic transmission ar a hydraulically lifted fifth-whE coupling. It is intended for rm shalling semi-trailers at port t( minals and is also suitable f ro-ro traffic.

The DAF range extends fro the six-ton gvw of the Club Four model up to the 150-tc gtvy of the DKS-engined 2E variants. DAF was one of ti first of the Continent manufacturers to build E eight-wheeler which made i debut at Earl's Court in 197, As far as the UK is concerne the DAF range does not go b low the 16-ton category ar there are no plans at the m ment to extend this by bringir in the Club trucks.

The top-of-the-range DK: engined 2800 was one of

st European models to feature let charge-cooling. Now the 4F 2300 uses a similar system Id other manufacturers, nobly Berliet and Volvo, have ined in. Although DAF is a len advocate of turbocharging, yt all the range is so equipped. ie 16-ton FA2105, for :ample, is naturally aspirated. Although the UK range ex: nds from 16 to 50 tonnes us, OAF covers the market ith only two basic engine de

both in-line six-cylinder iits of 8.25 and 11.6 litres 03 8n d 708cuin) respectively.

BELGIUM

ELGIUM is well served with JS and coach builders, as both an Hool and Jonckheere are sed there.

The first product from the >mparty of Bernard van Hool came in 1947. It was a practically hand-made bus body on a former military chassis. By 1957 he was employing 500 people and then in 1964 the company branched out into semi-trailer production.

When Bernard van Hoof died in 1974, the Koningshooikt factory alone employed 2000 people and was producing five buses per day. In the same year, the foundations were laid for a new semi-trailer factory — again at Koningshooikt — with a capacity of 20 units per day.

Van Hool also has a production plant at Saragossa in Spain, which supplies the Spanish home market and the exports for Latin America and Africa. The company also participates in Cummins Nordeste of BahiaBrazil as a chassis manufacturer, alongside Cummins and Brazilian bodybuiler Marcopolo.

Jonckhaere is another export-conscious company, with over 60 per cent of its production so allocated. Export markets range as far afield as Canada and the USA to Zaire and Zan bia.

Although there is no produi tion facility in the country, Be glum is the European heat quarters for International Han ester. Located at Brussels, it the control centre of 1H busine:. in the UK and South Africa wit Barney White of Seddon Atkir son, for example, reportin directly to the Belgian office.

The Brussels office al: handles the sales of all IH pn duets for Europe, Africa and if Middle East. This includes th whole American IH range, th vast majority of which COME directly from the USA for if Middle East but other marke include Turkey, Tunisia, Keny Egypt and the Sudan.

The vehicle range extenc from the Scout at the bottom 1 the PayStar at the top. It is e: pected that 2000 chassis will t processed through Brussel during 1979, with a furtht 1200 Scouts to be added to th total.