The Main Factors in Braking on commercial vehicles

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

A Rdsume of a Well-informed Paper by Mr. F. J. Field, M.I.A.E., Chief Engineer of Ferodo, Ltd., in which some Interesting Facts are Incorporated on the subject of Brakes and Braking

THE problem of motor-vehicle braking in general and the methods by which efficient retardation can be achieved always, arouse considerable interest, and, for that reason, we are sure that many of our readers will derive useful knowledge from points raised in a paper recently prepared by Mr. F. J. Field, M.I.A.E., chief engineer of Ferodo, Ltd.

The title chosen for this paper is "The Main Factors Involved in the Retardation of Commercial Motor Vehicles," and it gives some idea of the comprehensive manner in which the subject has been tackled. Mr. Field presents the essential features connected with the braking of motor vehicles in a simple manner, and includes in his paper information on many aspects of the problem, together with a description of various systems in general use on commercial vehicles.

At the outset the author gives some facts regarding the retardation and stopping distances on level roads. The rate of retardation and the stopping distance are governed equally by the retarding force exerted by the application of the brakes and the coefficient of friction between the tyres and the road surface. The rate of retardation is the product of the braking force, the weight on the wheels and the coefficient of friction of the tyre on the road.

100 Per Cent. Braking Efficiency.

It is convenient to describe the rale of retardation of 32.2 ft. per second per second as 100 per cent, braking efficiency and, since the stopping distance from any given speed is directly proportional to the coefficient of friction (which, in this case, may be regarded as equivalent to the percentage of braking efficiency), then, where the coefficient of friction equals .7, the braking efficiency will be 70 per cent., and so on.

It would, therefore, appear that braking efficiency on a level road can never exceed the coefficient of friction value of that road. It is, in fact, likely to be substantially less, according to the power of the brakes and to the condition of the treads of the tyres.

The author puts forward a plea for some means to be provided whereby brake power can be reduced or increased to meet varying road conditions. He suggests that, where compressed air or vacuum cylinders are fitted, it could be B30 effected by a simple form of release valve connected to a dial within easy reach of the driver, the dial being marked " Icy, Greasy, Wet or Dry." The movement of the pointer from one section of the dial to another would result in a suitable brake force being provided for any condition of the road.

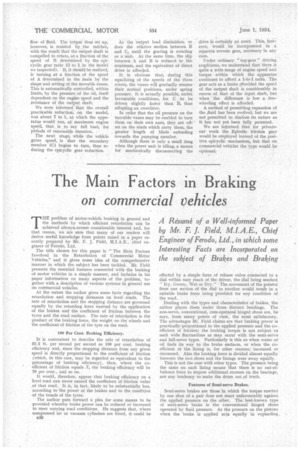

Dealing with the types and characteristics of brakes, the author places them under three distinct headings, The non-servo, conventional, cam-operated hinged shoes are, he says, from many points of vie*, the most satisfactory. The advantages Mr. Field claims are that braking power is practically proportional to the applied pressure and the coefficient of friction; the braking torque is not subject to such wide fluctuations as may occur with the semi-servo and full-servo types. Particularly is this so when water or oil finds its way to the brake surfaces, or when the coefficient of the lining is, for other reasons,' increased or decreased. Also the braking force is divided almost equally between the two shoes and the linings wear away equally.

This is not the case with other types. The pressure being the same on each lining means that there is no out-ofbalance force to impose additional stresses on the bearings, nor any tendency to make the drum out of truth.

Features of Semi-servo Brakes.

Semi-servo brakes are those in which the torque exerted by one shoe of a pair does not react unfavourably against the applied pressure on the other. The best-known type of semi-servo brake is the conventional hinged shoes operated by fluid pressure. As the pressure on the pistons when the brake is applied acts equally in expanding.

each shoe, as one shoe opens in the direction of the rotation of the drum the pressure normal to the surface of the 'lining is increased substantially by the selfenergizing property of that shoe..

The author expresses the view that the Benda Duo Servo gives the highest degree of self-energizing of any brake. There are two shoes—the primary and secondary. As will be seen from one of the accompanying Mistral' tions, the pressure on the free end of the primary shoe creates a certain torque, which is transmitted, plus the original applied pressure, to the free end of the secondary shoe. The secondary shoe possesses the same degree of self-energization as the primary, and, in turn, produces a force greater than that forthcoming from the primary shoe.

Adding these two forces together, there is a considerable increase of effort, with a result that comparatively light operating pressure will create a braking force greater than can be produced by the same operating pressure by any other means.

Referring to the relative power of bfakes of different types, Mr. Field illustrates his paper with an interesting diagram. Perusing this we see that, taking a coefficient of friction of 0.3 for a common total operating pressure, the Bendix Duo Servo brake is three times more powerful than is the conventional type of shoe with direct Lockheed operation.

The advantage of the Lockheed method over cam operation is 1.2 to 1, but, as the coefficient of fricti6n increases, the difference between the full-servo and semi-servo also increases. The dotted lines indicate the large difference between the forces produced by individual shoes of a pair when one shoe is fully self-energizing, as results from direct Lockheed operation. The author then considers the question of cams, where cam-operated brakes are used. 170 points out that, where a high-leverage cam is fitted, it may be necessary to insert packing pieces from time to time between the cams and the ends of the shoes. Given a low-leverage cam it is, however, sometimes possible to take full advantage of the useful thickness of the lining without resdrting to packing pieces.

In view of the labour involved in dismantling wheels and brake drums, there would appear to be something in favour of thinner linings and low-leverage cams. On the other hand, the question arises as to the desirability of running for long periods without any attention being given to theinternal part of the brakes. The use of high-leverage cams leads directly to periodic inspection of the brake shoes and operating gear against which nothing can possibly be said.

The author, in a reference to brake drums, is of the ,opinion that castings of either plain castiron or cast-alloy irons, containing small percentages of chromium, nickel and manganese, will entirely supersede pressed-steel driams in the heavy commercial field. He looks upon the insertion of a cast-iron liner into a steel shell as a compromise which cannot be regarded as altogether satisfactory. A composite drum can, however, be made much more efficient by coating the outside of the cast-iron liner with copper, but the author feels that the cost will prove a deterrent to its adoption.

Mr. Field concludes with some interesting remarks, on brake lining. Speaking generally, the choice of lining lies between non-metallic woven asbestos fabric and woven fabrics in which brass, lead and zinc-alloy wire are incorporated. There are also the hard, moulded varieties, and the latter are generally the choice of the principal transport companies in this country.