THE SPRINGING OF COMMERCIAL VEHICLES.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Types of Springs Where Improvements Have Been Effected. Double Cantilever Springs and Their Possibilities.

IT IS SOMEWHAT SURPRISING that so few real improvements have been made in the -springing of commercial vehicles, apart from, lengthening the springs, strengthening them by turning one or more of the leaves round the spring eyes, and stopping the old practice of drilling the springs at their weakest point for the spring bolts. In few instances are springs radically different from what they were in the davs of horse-drawn vehicles; many attempts, more or less successful, have been made to render them more supple when motor vehicles are running light, by the provision of auxiliary springs in the form of leaves with adifferent camber, spirals, or volutes. These take a considerable portion of the weight when the vehicle is running loaded and enable the main springs to be lightened accordingly.

In spite of such attempts it would appear that the springing of commercial vehicles is far behind that of private cars. That this should be the case is somewhat surprising, considering the vast progress which has been made during the last few years in the design of other parts of commercial vehicles, and that the future success of the commercial vehicl.e movemerir depends to a great extent on the safe transport of more or less fragile goods, which, in many cases, are liable to damage through vibration. The conveyance of passengers may also be classed with the conveyance of goods of a fragile nature, as. although the former may be able to withstand the, effects of vibration, they will not feel very much inclined to do so, and, consequently, the springing of passenger vehicles is just as important, if not. more so than of those for the conveyance of goods.

The springs generally employed on commercial vehicles are practically, always of the semi-elliptic type. Certainly this type has been perfected by several manufacturers and has now reached. the stage when further improvement becomes difficult. if no impossible. Therefore, as further improve

ment in springs is called for, the necessity of adopting some other type is apparent. On private cars several different types of springs are employed, including the doubl e elliptic, three quarter elliptic, and half-elliptic in which one end of the spring is clamped to the frame and the other to the

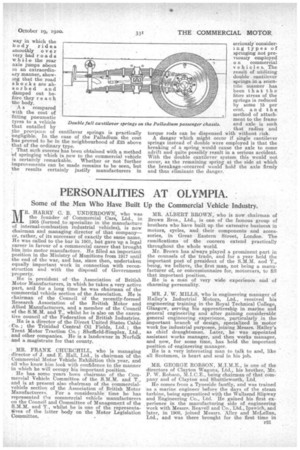

axle. The half-elliptic is A full cantilever spring really a spring of the

F20 cantilever type, and from it has developed the full cantilever type in which the centre of the spring is supported by a rocking piece, whilst one end is fixed to the axle and the other to a spring bracket of the ordinary type. There are also several modifications of this latter type, as in the Wolseley, where the cross-bar joining the two rocking pieces is firmly fixed to the latter, so that movement of one spring causes corresponding movement in the other. In the Citroen car two half-elliptics are employed at the rear, both being fastened to the axle at one end and to the frame at the other, but no successfui attempts have as yet been made with private cars to embody double full cantilever springs. It has been left to the manufacturers of a commercial vehicle to make this refinement, which is incorporated in one of the Palladium chassis now on view at Olympia. The rear springing at each side of the four-ton Palladium consists of two superimposed cantilever springs, both secured at their centres to the same rocking bracket. The latter fulcrums on a shaft held by a bracket bolted to the side member. The rear ends of the springs are attached by bolts to a special spring seat on the rear axle one spring being secured to the top of the seat and to the 'bottom. The front ends of koth springs are supported in a double spring link, the top of which swivels on a shackle pin firmly secured to the frame side member and the bottom portion of the double link swivels an a shackle pin carried by the top link.

We recently carried out a, trial run on a. Palladium chassis fitted with the new double cantilever springs at the rear and carrying a load of VI tons. Although the tyres fitted were solid, the running was so smooth, even over roads full of pot-holes, that it wgs difficult to believe that pneumatics were not fitted..

One of the great advantages which accrue with this method of springing is that the unsprung weight of the back axle is reduced to the extent of some

thing like 4 cwt. This is a most important point, as unsprung weight is one of the main causes of excessive tyre wear and also of damage to the roads. The whole aim of the design in the case of the Palladium vehicle has been to attain a low spring periodicity with a. high degree of flexi

bility. That this object

as embodied in certain has been attained in full

measure is proved by the way in which the body rides smoothly over very bad roads whil-e the rear axle jumps about in an extraordinary manner, showing that the road shocks are absorbed and damped out before they r eaels the body. ' A a compared with the cost of fitting pneumatic tyres to a vehicle that entailed by the provision of cantilever springs is practically egligib le. In the case of the Palladium the cost has proved to be in the neighbourhood of £25 above that of the ordinary type. • That such success has been obtained with a method Of springing which is new to the commercial vehicle is certainly remarkable. Whether or not further improvements can be made remains to be seen, but 'the results certainly justify manufacturers in

seriously" considering types of springing not previously employed o n commercial vehicles. The result of utilizing double cantilever springs in a scientific manner has been that the fibre stress of the springs is reduced by some 15 per cent, and the method of attachment to the frame and axle is such that radius and torque rods can be dispensed with without risk. A danger which might occur if single cantilever springs instead of double were employed is that the breaking of a spring would cause the axle to come adrift and quite possibly result in a serious accident. With the double cantilever system this would not occur, as the remaining spring at the side at which the breakage -occurred wouldhold the axle firmly and thus eliminate the danger.