Proof of the pudding

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Stripped after 368,000 miles, and inspected in the presence of Commercial Motor, a Cummins NH 180 proves in remarkably fine condition

By R. D. CATER, AM InstBE • When amendments to the Construction and Use Regulations in 1964 raised the maximum permissible gross vehicle weight to 32 tons the haulage industry seriously started to look for higher horsepowers than were then in use. This was a move which immediately opened the door to the Cummins NH series of in-line six-cylinder diesels. But although these were extremely well-proven units, they were not widely known at that time in the UK, and there was an attitude of "show me" on the part of some operators—especially on the score of reliability. Now, four years later, the pudding is being proven by NH engines which have reached, and in many cases passed, the magic 250,000-mile mark which a few years ago was reckoned as the useful working life of the majority of goods vehicles' engines.

We were recently invited to visit the Shotts factory of Cummins Engine Co. Ltd. where an NHE 180 B engine which, installed in a Guy Invincible MkIII, went into service on a Maddiston to London trunk service via Al on April I 1965, was being stripped for inspection. The recorded mileage on the vehicle when the engine was removed was 350,509, but there was a further 18,000 miles to take into account, during which the mileage recorder was out of action,, so the 'actual mileage on the engine at time of stripping was in fact around 368,000.

What was the engine's history? The records kept by the operators, J. and A. Smith of Maddiston Ltd., showed that at 13,294 miles, some foreign matter (minute swarf particles) had been found in the fuel pump, which had entailed cleaning and refitting the pump. At 122,000 miles the cause of a sudden fall in performance was untraced, but was cured by installing six replacement injectors. At that stage it was expedient that the trouble should be cleared up in the shortest possible time but it appears that re-torquing of the injectors would probably have cured the fall in performance.

A water leak developed at 235,000 miles as the result of the rubber grommets between heads and block failing. These components have since been redesigned, overcoming the problem. Mr Hugh Robinson, Smith of Maddiston's engineer, thought it prudent at this high mileage to fit exchange heads and this was done although, he assured me, there were no signs which would have caused the less prudent to do so.

Throughout the vehicle's life it had run approximately 2,600 miles a week, doing through round trips to London and being handled by four drivers per round trip. In the engine's favour was the fact that the machine was always running laden, a point which made for engine temperatures being kept well up. Servicing had been carried out at approximately 8,000-mile intervals, but had on occasion run to 12,000, while the lubricant used in the engine had been Shell Rotella T.30. Oil filters had been changed with every oil change. None of the defects recorded had immobilized the vehicle, it having returned to base under its own power on every occasion.

Unfortunately a recent accident severely damaged the vehicle, the engine sustaining a cracked fuel pump carrier. It was for this reason that it was removed from the chassis and returned to Cummins for inspection. At the time of the accident the vehicle was performing satisfactorily and still returning the same fuel consumption that it had throughout its operational life, 6.8mpg.

Before the engine was stripped it was given a test run on a dynamometer. When new, it had produced 174 bhp net and 470 lb.ft net at 1,950 rpm. Placed on test as -removed from the chassis it produced 151 bhp and 407 lb.ft at 1,950 rpm. By changing the injectors but making no other alterations the specific fuel consumption was reduced from 0.437 lb per bhp /hr to 0.397 lb per bhp /hr, while the bhp output was raised from 151 bhp to 163 bhp. Oil pressure recordings were taken and these proved to be, at idling speed, 28 psi, at full rated speed 63 psi. When new these figures were 31 and 67 psi respectively.

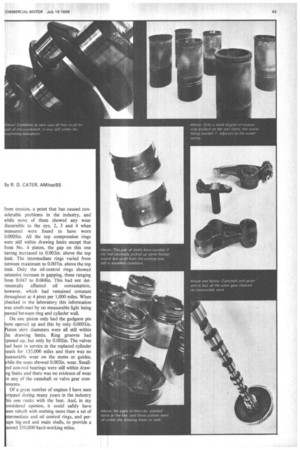

Remarkably low wear readings were evident despite the high mileage. The crankshaft journals were all still within the tolerances allowed during production, as were the bearing shells of the mains. The big-end shells showed only 0.00025in. wear and in fact the 0.0002in. flash which is applied during manufacture was still intact on all but one pair of shells. On this pair some foreign matter had been present and a tramline scoring was evident, although I do not feel that the bearing would have come to any harm during the remainder of the engine's life.

Cylinder liners were remarkably free from erosion, a point that has caused considerable problems in the industry, and while none of them showed any wear discernible to the eye, 2, 3 and 4 when measured were found to have worn D.0005in. All the top compression rings were still within drawing limits except that from No. 4 piston, the gap on this one having increased to 0.002in. above the top Limit. The intermediate rings varied from between maximum to 0.007in. above the top Limit. Only the oil-control rings showed extensive increase in gapping, these ranging from 0.047 to 0.068in. This had not detrimentally affected oil consumption, however. which had remained constant throughout at 4 pints per 1,000 miles_ When hecked in the laboratory this information as confirmed by no measurable light being assed between ring and cylinder wall.

On one piston only had the gudgeon pin re opened up and this by only 0.0001in. ston skirt diameters were all still within

I

he drawing limits. Ring grooves had pened up, but only by 0.002in. The valves ad been in service in the replaced cylinder eads for 133,000 miles and there was no easurable wear on the stems or guides, hide the seats showed 0.002in. wear. Smallnd con-rod bearings were still within draw

rig limits and there was no evidence of wear n any of the camshaft or valve gear comonents.

Of a great number of engines I have seen tripped during many years in the industry is one ranks with the best. And, in my nsidered opinion, it could safely have een rebuilt with nothing more than a set of termediate and oil control rings, and peraps big-end and main shells, to provide a econd 350,000 hard-working miles.