LONG LIFE: GUARANTEED

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

Tanker operators have to cope with corrosive loads and fire screening regulations. A wide range of extended anti-corrision warranties and fire-screening equipment is available; but terms and prices do vary enormously.

• The Tankcon exhibition provides a good opportunity to review the current trends in cab warranties. Tanker operators tend to keep vehicles longer than most and are involved in a high profile business, so their demand for good cab performance is hardly surprising.

Since pressed steel cabs finally displaced the traditional wood framed, alloy panel coachbuilt units, operators have been finding out about corrosion the hard way. British weather is a tough environment for any steel structure — as this country's steel cabs have shown. While home producers struggled to overcome the distressing tendency for steel pressings to crumble away during the sixties and early seventies, continental vehicles first trickled then flooded on to the UK market.

For all the improved comfort that these vehicles offered, operators still faced the problem of fast rotting cab structures because the continental cabs of that period were at least as vulnerable to rust as the home-built products.

Two manufacturers, ERF and Foden, decided to minimise this problem by continuing the development of non-metallic materials for cab panelling. ERF's eightyear unconditional cab warranty on its SP4 steel framed, SMC panelled cab is the longest currently available. Despite its use of similar GRP panels, Foden, surprisingly, does not offer a special cab warranty.

In recent years much has been learnt about minimising the effect of corrosion at the design stage. As in the car industry, truck cab designers have been able to eradicate many of the water/mud traps that flawed earlier designs. This, combined with the arrival of better anticorrosion treatment for steel, has markedly improved steel cab longevity — but even now there is a vast difference between the corrosion resistance of the steel cabs produced by the various truck manufacturers.

Even the largest operators are not generally equipped to restore corrosion damaged cabs, so they have to use outside specialists with the accompanying downtime and expense.

Considering the degree of concern among truck operators, there are still a surprising number of manufacturers who only offer base 12-month chassis warranty on their cabs.

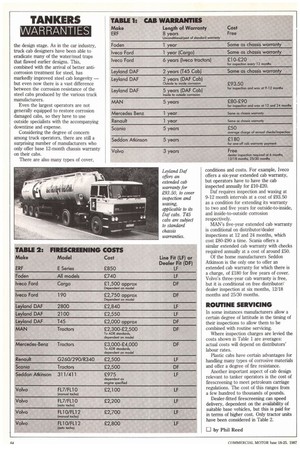

There are also many types of cover, conditions and costs. For example, Iveco offers a six-year extended cab warranty, but operators have to have the cab inspected annually for 210420.

Daf requires inspection and waxing at 9-12 month intervals at a cost of 293.50 as a condition for extending its warranty to two and five years for outside-to-inside, and inside-to-outside corrosion respectively.

MAN's five-year extended cab warranty is conditional on distributor/dealer inspections at 12 and 24 months, which cost £80-£90 a time. Scania offers a similar extended cab warranty with checks required annually at a cost of around £50.

Of the home manufacturers Seddon Atkinson is the only one to offer an extended cab warranty for which there is a charge, of £180 for five years of cover. Volvo's three-year cab warranty is free, but it is conditional on free distributor/ dealer inspection at six months, 12/18 months and 25/30 months.

ROUTINE SERVICING

In some instances manufacturers allow a certain degree of lattitude in the timing of their inspections to allow them to be combined with routine servicing.

Where inspection charges are levied the costs shown in Table 1 are averages: actual costs will depend on distributors' labour rates.

Plastic cabs have certain advantages for handling many types of corrosive materials and offer a degree of fire resistance.

Another important aspect of cab design relevant to tanker operators is the cost of firescreening to meet petroleum carriage regulations. The cost of this ranges from a few hundred to thousands of pounds.

Dealer-fitted firescreening can speed delivery, dependent on the availability of suitable base vehicles, but this is paid for in terms of higher cost. Only tractor units have been considered in Table 2.

El by Phil Reed