SIX•WHE WONDER

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

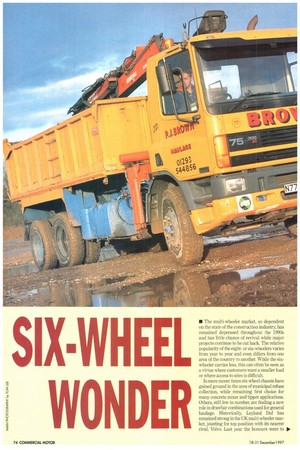

• The multi-wheeler market, so dependent on the state of the construction industry, has remained depressed throughout the 1990s and has little chance of revival while major projects continue to be cut back. The relative popularity of the eightor six-wheelers varies from year to year and even differs from one area of the country to another. While the sixwheeler carries less, this can often be seen as a virtue where customers want a smaller load or where access to sites is difficult.

In more recent times six-wheel chassis have gained ground in the area of municipal refuse collection, while remaining first choice for many concrete mixer and tipper applications. Others, still few in number, are finding a new role in drawbar combinations used for general haulage. Historically, Leyland Daf has remained strong in the UK multi-wheeler market, jousting for top position with its nearest rival, Volvo. Last year the honours went to OP. y the time we tested the 75 Series six

wheeler in wheeler in October 1995 Daf had moved to the Euro-2 low-emission engine spec—almost 12 months before the deadline.

The main difference to its 75.300 6x4 was an increase in price of £2,000 and a dramatic 300rpm shift upwards to gain maximum torque Our 4.55m-wheelbase chassis also included the 2F Intarder (a hydrodynamic retarded which weighed only 80kg but cost a hefty £4,200. The longer (5.0m) wheelbase, with longer rear overhang, was better suited to general haulage There was nothing about the engine, gearbox or handling to worry even the least experienced driver With torque peaking at 1,700rpm it wouldn't slog on at much lower revs and it needed to be taken to 2,000rpm at the top of the green before changing up. In top gear peak torque equated to about 50mph. The Egas cruise control hesitated on pickup but this was said to be atypical and could easily be corrected. Handling was good for a tipper and its service brakes pulled up quickly, if a little out of line under heavy pressure The Intarder was very easy to use and a lot more effective than the standard exhaust brake. Payload was not its strongest point as it gave away about 600kg to the Euro-1 version of the Iveco Super Cargo, but with a return of 9.85mpg the Daf 75.300 was a , gnat's whisker short on top fuel conf' sumption. The best recorded on CM'S Midlands route was 10mpg, by Scania's old 280. Mouldings around the steps looked vulnerable. Velour seats were cosy, if not the most practical, but the rest of the cab had a wipe-clean finish. The mechanically sprung seat gave a comfortable ride and noise levels were lower than those of some other 6x4 trucks we had tested. There wasn't much room behind the seats to stow coats, boots or even a lunchbox, but at least the overhead trays were deep enough for documents.

Leyland Dd. which claimed

\A.41 just over a 20% _ thireiarkfeewtesrhartehaonf o 5,000 units sold in

this sector. As a group Iveco took third spot with Scania, Foden and ERF all within a few percentage points, but no two together matched the output from Leyland Dd.

• EVOLUTION

As in all sectors of the market, those who buy six-wheelers are increasingly looking for more powerful vehicles to optimise journey times and fuel use, and manufacturers are prepared to accommodate them. Where 250hp was considered about the norm for a rigid six-wheeler in 1991, 300bp is not at all unusual today.

When Daf introduced its new generation of 75 Series models in May 1993, its 8.65-litre charge-cooled Euro-1 six-cylinder engine was offered at three ratings of 245, 272 and 302hp. This power unit was developed from the 8.25litre block used in the long-serving Daf 2300 and 2,500 chassis.

The extra capacity was achieved with a change of crank and by increasing the length of the stroke by 18mm while the casing was strengthened and a new crossflow head introduced to improve the breathing. With the extra power came more torque, with the overall result that it was more fuel efficient over a wider rev range than ever before, achieving a

specific fuel consumption of less than 200g/kWh from 1,000-2,000rpm.

A single-plate clutch transfers the power to a nine-speed ZF all-synchromesh transmission while a new stronger chassis was introduced to keep down both its weight and overall height. In 1993 the permissible gross weight for a rigid chassis was increased to 26 tonnes with a road-friendly suspension. While air suspension is available for drawbar applications for use up to 35 tonnes on four axles, the conventional tipper chassis with double-drive comes with steel multi-leaf packs which pivot about a central trunnion and are located by eight reaction rods. It does not include an anti-roll bar but spring travel is limited by four cables attached to the chassis. Not deemed to be road friendly, axle limits were restricted to 9.5 tonnes.

A stylish cab with narrow front dimension widening towards the rear offers a low floor height of 1.038m while maximising the width across the seating area. The 75 Series cab also meets the Swedish cab crush test. A day cab is standard on all rigid chassis.

• OPERATORS

Jack Haley, transport and plant manager for Torbay Council, is responsible for the local authority's transport at Contract Services in Paigriton, Devon. He has 170 vehicles under his supervision, ranging from car-derived vans through to 26-tonne refuse collectors. By next April, as the local authority takes over extra responsibilities from the county council, the fleet is expected to grow by a further 30 to 40 vehicles. In the last quarter of 1996 the authority needed six new domestic refuse collection vehicles that would cope with the hilly terrain in the Torbay area, The contract was tendered out and the Leyland Daf 75.270 was selected on price, known durability and local dealer backup. Part of the deal was that the vehicles would be bodied and delivered ready for use within three months. The order was placed at the end of October. Unusually, the chassis were delivered from Eindhoven directly to the French body builder Semat, which also installed the bin lifting equipment, and they were ready to go into service by the beginning of February this year.

"We have had very little trouble with them since," says Haley. "We specified the 6x4 with the Allison World Series automatic gearbox. It's ideal for this type of urban stop-go operation. It's kinder to the driveline, as well as being less fatiguing for the driver. Although operating for 50 to 60 hours a week, the distance each collection vehicle travels is quite low—only 500 miles a month. Fuel consumption of 2.5mpg may seem high but it's what we expect on this type of work."

"Each truck gives us a payload of 11 tonnes and they collect two to three loads a day," he adds. "We expect to run them for seven years. Then, depending on reliability and condition, we will either extend their use or replace them completely. Because we purchased them on an operating lease their condition is important to us at the end of the day if it means that they incur any cost on their return. Tyre wear is considerable. We fit Waste Master tyres to the rear and urban pattern tyres to the front axle. Usually the whole set needs to be replaced after just 6,000 miles.

"Originally the day cab had individual seating for the driver and a two-man crew," says Haley, "but we have since changed to a bench seat to accommodate a crew of three. A camera fitted at the rear of the vehicle not only makes it safer for the crew and any traffic approaching from behind, but it also speeds up the work. Overall, we are well pleased with both the chassis and the body. The payload met our expectations. Next time round we will probably specify a rear steer axle to improve tyre wear. The payload will remain about the same as now."

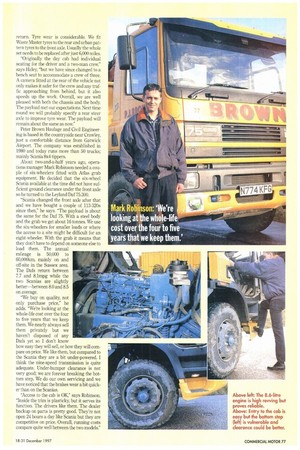

Peter Brown Haulage and Civil Engineering is based in the countryside near Crawley, just a comfortable distance from Gatwick Airport. The company was established in 1980 and today runs more than 50 trucks; mainly Scania 8x4 tippers.

About two-and-a-half years ago, operations manager Mark Robinson needed a couple of six-wheelers fitted with Atlas grab equipment. He decided that the six-wheel Scania available at the time did not have sufficient ground clearance under the front axle so he turned to the Leyland Daf 75.300.

"Scania changed the front axle after that and we have bought a couple of 113-320s since then," he says. "The payload is about the same for the Daf 75. With a steel body and the grab we get about 16 tonnes. We use the six-wheelers for smaller loads or where the access to a site might be difficult for an eight-wheeler. With the grab it means that they don't have to depend on someone else to load them. The annual mileage is 50,000 to 60,000km, mainly on and off-site in the Sussex area. The Dafs return between 73 and 8.1mpg while the two Scanias are slightly better—between 8.0 and 8.5 on average.

"We buy on quality, not only purchase price," he adds. "We're looking at the whole-life cost over the four to five years that we keep them. We nearly always sell them privately but we haven't disposed of any Dafs yet so I don't know how easy they will sell, or how they will compare on price. We like them, but compared to the Scania they are a bit under-powered. I think the nine-speed transmission is quite adequate. Under-bumper clearance is not very good; we are forever breaking the bottom step. We do our own servicing and we have noticed that the brakes wear a bit quicker than on the Scanias.

"Access to the cab is OK," says Robinson. "Inside the trim is plasticky, but it serves its function. The drivers like them. The dealer backup on parts is pretty good. They're not open 24 hours a day like Scania but they are competitive on price. Overall, running costs compare quite well between the two models." Amec is another corn• pany with interests in construction and civil engineering works; it has used Leyland Daf 75 6x4 tippers on contracts for the utilities over the past few years. Neil Cuthbertson is workshop foreman at the company's Renfrew depot. We look after 15 26-tonners," he says. "Ten of them are Daf 75 Series, the others are ERFs and Ivecos. Generally they are easy to maintain. The engines have been completely reliable. The brake linings don't last as long as maybe we would like but they're on a different kind of work to the other trucks. Each of the 75 Series is fitted with an Atlas grab and they tend to be used in housing estates where there's a lot of stopping and starting.

"We have had a couple of broken springs but it's not a common failure," says Cuthbertson. "The wee valve for the range change on the gearbox has given us a few problems through sticking, leaving the selector in either the high or low part of the box. We get the odd problem with the electrics but nothing specific that keeps recurring. The cabs stand up to the work OK."

• DEALERS

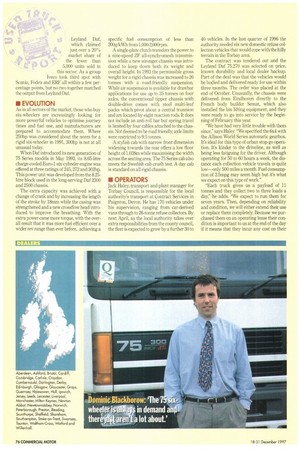

While in the West Country we dropped into Wessex Leyland Daf at Newton Abbot. General manager Dominic Blackborow told us that Leyland Daf claims 52.8% of the six wheeler market in Devon and Cornwall.

"The 75 Series six-wheeler is very popular in this part of the country and it's been a very good model for us," he said. "It followed on behind the old Daf 2300 with the same strong back end but with a cab that is much more appealing to the driver. The bulk of our sales are 6x4 tippers but we do sell a few 6x2s for haulage and the occasional one for drawbar work. The 8.6-litre engine gives a choice of power from 240 to 300hp.

"We mostly sell the 300hp version in this area because of the terrain," he adds, "hut the 270 is most popular throughout the rest of the country. The municipal market usually goes for the 6x4 if the truck has to go onto landfill sites, but we do a municipal rear-steer version at 25.5 tonnes GVW and it doesn't lose anything on payload. The Allison box is very reliable. They all go for it—municipal trucks—but it's too expensive for general haulage. It costs about £9,000 extra "The ZF Intarder is an interesting option which we get asked about a lot," he says. "It's probably the lightest of the transmission retarders but the price still puts many operators off. Even though they accept that there is a safety element they say that £4,500 buys a lot of linings and drums. To counteract that we point to the savings in downtime and the added residual value. The 75 Series compares well on weight with the competition and with an aluminium body it will give a payload of about 17 tonnes.

"We deal in used trucks," he adds, "but carry only a small stock so we're not part of the Dafapproved used truck scheme. The 75 six-wheeler is always in demand and there just aren't a lot about. The book puts the retail price for an L-reg 270 at £27,000, but for the right spec in good condition you can expect to pay up to £5,000 more than that.

"The 6x2 with a steer axle is about £1,000 less than the 6x2 when new, but there is only a small percentage sold with that spec," he says. "On average, tippers cover 6080,000km a year and haulage models up to 120,000km. There will always be a demand for late tipper models."

John May at Chaddesley Commercials, based at Kidderminster, is one of the few independent dealers to have advertised a Leyland Daf 75 Series six-wheeler in Commercial Motor's classified section over the past 18 months. "All good quality stock is in very short supply," he says. "The trucks are built better today so it often pays an operator to keep them longer. The truck has to relate to the job and the 75-Series six-wheeler is a good seller. It's got a modern cab and it is a good all-round vehicle. The trend is for more power, but the 270 is probably still the most popular model for tipping work. You can't go by the book on prices as they are only a guide to a truck in average condition and there can be many thousand of pounds separating the good and bad."

• SUMMARY

Sales of new multi-wheelers have been depressed by the state of the construction industry throughout this decade, but modern trucks are built to a higher quality than ever before. Overall, operators tend to keep them longer and there is a shortage of late models in good condition.

The 75 Series six-wheeler, available only since 1993, has a good reputation and the best examples fetch over book prices. The extra power of the 75.300 is more popular in hilly areas. The Euro-2 version of Dais 8.6litre engine can be described as a high revving unit but it mates well with the ZF synchromesh box.

The bottom line is, if you want one, and you can get one—have one!

=I by Bill Brock

SPECIFICATIONS

MODEL Leyland Daf FAT 75.300 6x4 tipper chassis with day cab. GVW: 26.0 tonnes.

Manufacturer: Daf Trucks NV, Eindhoven, Holland.

ENGINE: Dal RS222L Euro-2, charge-cooled diesel. Cylinders: Six in line. Capacity: 8.6 litres. Maximum net power: 298hp (222kW) at 2,300rpm. Maximum net torque: 833 lbft (1 ,130Nm) at 1,700rpm.

TRANSMISSION: ZF9S-109 eight-speed synchromesh with a 400mm single-dry-plate clutch.

Final drive: Da/ 1132T single-reduction tandem bogie with cross-axle and inter-axle diff-locks; ratio, 4.10:1.

BRAKING SYSTEM: Dual-circuit air system with load sensing on the drive axles, air dryer and automatic slack adjusters. Parking: Spring brake actuators on the first and third axles.

STEERING: Hydraulic power assisted.

CHASSIS: Flat topped steel frame with bolted cross-members. Suspension: Front, parabolic springs with anti-roll bar; rear, two-spring bogie with semi-elliptic springs and check straps.

Wheelbase: 4.55m.

Wheels and tyres: 8.25x22.5 10-stud wheels with 295/80R22.5 tyres. Fuel tank: 300 litres.

ELECTRICAL SYSTEM: 24V, 2x15Ah batteries with 55A alternator.

PARTS PRICES

Manufacturer's prices (retail ex VAT) Laminated windscreen £152.03 Injector set (six, service exchange) £182.64 Piston liner set (six) £1,116.48 Rear spring brake chamber (exchange) £231.61 Complete headlamp unit £123.18 Wiper blades (complete set) £35.30 Engine oil filter £17.75 Complete clutch assembly (exchange) £474.60 Door mirror (complete) £33.40

WORKSHOP TIMES

Manufacturer's standard workshop hours Remove and replace clutch assembly 3.7 Remove and replace one injector 0.6 Replace head gasket (both) 10.7 Replace brake shoes, front and rear 7.8 Remove and replace engine 8.0 Remove and replace gearbox 3.5 Renew engine oil filter(s) 0.1

ROADTESTS

Leyland Daf 75.300 19.10.95

WORKSHOP WAYS

Leyland Daf 75.300 Sept 1994