A Heavy-fuel Gasifier for Petrol Engines

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

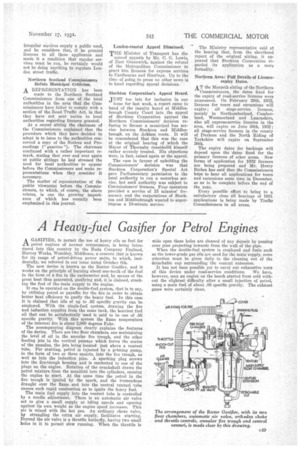

A GASIFIER, to permit the use of heavy oils as fuel for petrol engines of normal compression, is being introduced into this country by the Buda. Company England, Harvey Works, Wembley, Middlesex, a concern that is known for its range of petrol-driven power units, to which, incidentally, we referred in our issue dated October 6th.

The new device is known as the Rector Gasifier, and it works on the principle of burning about one-tenth of the fuel in the form of a fire in the carburetter and, by means of the great heat thus generated, gasifying and, it is claimed, cracking the fuel of tho main supply to the engine.

It can be operated on the double-fuel system, that is to say, by utilizing petrol or paraffin for the fire in order to obtain better heat efficiency to gasify the heavy fuel. In this case it is claimed that oils of up to .92 specific gravity can be employed. With the single-fuel system, drawing the fire and induction supplies from the same tank, the heaviest fuel oil that can be satisfactorily used is said to be one of .88 specific gravity. With this system the flame temperature of the internal fire is about 2,000 degrees Fehr.

The accompanying diagram clearly explains the features of the device. There are two float chambers, one maintaining the level of oil in the annular fire trough, and the other feeding jets in the vertical passage which forms the centre of the annulus, the jets being located just above a venturi tube. For starting, petrol is injected by a priming pump, in the form of two or three squirts, into the fire trough, as well as into the induction pipe. A sparking plug screws into the fire-trough housing and is corutected to one of the plugs on the engine. Rotation of the crankshaft draws the petrol mixture from the manifold into the cylinders, causing the engine to start. At the same time the petrol in the Ere, trough is ignited by the spark, and the tremendous draught over the flame and into the central venturi tube causes such rapid combustion as to ignite the heavy fuel.

The main fuel supply into the venturi tube is controlled by a needle adjustment. There is an automatic air valve set to give a small supply at idling speeds and opening against its own weight as the engine speed increases. This air is mixed with the hot gas. An ordinary choke valve, by strangling the extra air supply, facilitates starting. Beyond the air valve is a throttle butterfly, having two small holes in it to permit slow running. When the throttle is wide open these holes are cleaned of any deposit by passing over pins projecting inwards from the wall of the pipe.

When the double-fuel system is employed and fuels such as the lower-grade gas oils are used for the main supply, some attention must be given daily to the cleaning out of the detachable cup surrounding the venturi extension.

It has not been possible yet to carry out exhaustive tests of this device under road-service conditions. We have, however, seen an engine on the bench started from cold without the slightest difficulty after a small injection of petrol, using a main fuel of about .86 specific gravity. The exhaust gases were certainly clean.