A PROMISING QUICK-C NGE OVERDRIVE GEAR

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

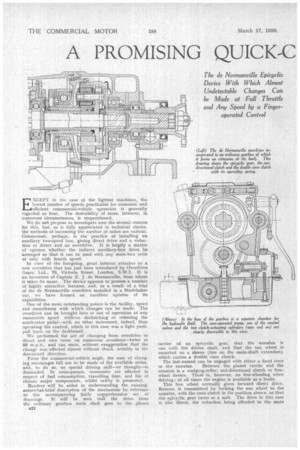

The de Normanville Epicyclic Device With Which Almost Undetectable Changes Can be Made at Full Throttle and Any Speed by a Finger operated Control

EXCEPT in the case of the lightest machines, the lowest number of speeds practicable for economic and efficient commercial-vehicle operation is generally regarded as four. The desirability of more, however, in numerous circumstances, is unquestioned. We do not prcpose to investigate now. the several reasons for this, but, as is fully appreciated in technical circles, the methods of increasing the number of ratios are various, Commonest, perhaps, is the practice of installing an auxiliary two-speed box, giving direct drive and a reduction or direct and an overdrive. It is largely a matter of opinion whether the indirect auxiliary-box drive be arranged so that it can be used with any main-box ratio or only with fourth speed. In view of the foregoing, great interest attaches to a new overdrive that has just been introduced by Overdrive Gears; Ltd.; 76, Victoria Street, London, S.W.1. It is an invention of Captain E. J. de Nornaanville, from whom it takes its name. The device appears to possess a number of highly attractive features, and, as a result of a trial of the de Normanville overdrive installed in a Studebaker car, we have formed an excellent opinion of its capabilities. One of the most ontstanding points is the facility, speed and smoothness with which changes can be made. The overdrive can be brought into or out of operation at any reasonable speed withent declutching or releasing the accelerator pedal—with no other movement, indeed, than operating the control, which in this case was a light pushpull knob on the dashboard. We performed the act of changing from overdrive to direct and vice versa on numerous occasions—twice at 80 m.p.h., and can state, without exaggeration that the change was effected almost without shock, notably in the downward direction. From the commercial-vehicle angle, the ease of changing encourages full use to be made of the available ratios, and, to do so, no special driving skill—or thought—is demanded. In consequence, economies are effected in respect of fuel consumption, travelling time, and life of chassis major components, whilst safety is promoted. Readers will be aided in understanding the ensuing, somewhat-brief description of the mechanism by reference to the accompanying fairly comprehensive set of

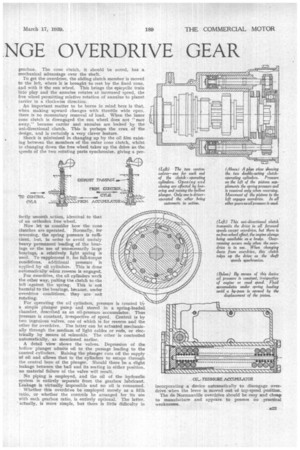

drawings. it will be 'seen that the drive from the ordinary gearbox main shaft goes to the planet B22

carrier of an epicyclic gear, that the annulus is one with the driven shaft, and that the sun wheel is mounted on a sleeve (free on the main-shaft extension) which carries a double cone clutch.

The last-named can be engaged with either a fixed cone

or the annulus. Between the planet carrier and the annulus is a wedging-roller, uni-directional clutch or freewheel device. There is, however, no free-wheeling when driving; at all times the engine is available as a brake. This free wheel normally gives forward direct drive. Reverse is transmitted by locking the sun wheel to the annulus, with the cone clutch in the position shown, so that the epicyclic gear turns as a unit. The drive in this case is also direct, the reduction being afforded in the main

gearbox. The cone clutch, it should be noted, has a mechanical advantage over the shaft.

To get the overdrive, the sliding clutch member is moved to the left, where it is brought to rest by the fixed cone. and with it the sun wheel. This brings the epicyclic train into play and the annuhas rotates at increased speed, the free wheel permitting relative rotation of annulus to planet carrier in a clockwise direction.

An important matter to be borne in mind here is that, when making upward changes with throttle wide open, there is no momentary removal of load. When the inner cone clutch is disengaged the sun wheel does not " race away," because carrier and annulus are locked by the uni-directional clutch. This is perhaps the crux of the design, and is certainly a very clever feature.

Shock is minimised in changing up by the oil film existing between the, members of the outer cone clutch, whilst in changing down the free wheel takes up the drive as the speeds of the two rotating parts synchronize, giving a per

fectly. smooth .action, identical to that of an orthodox free wheel.

Now let us consider how the cone clutches are operated. Normally, for reversing, the spring pressure is sufficient, but, in order to avoid unduly heavy permanent loading of the bearings or the use of unnecessarily large bearings, a relatively light spring is used. To supplement it, for full-torque conditions, additional pressure is applied by oil cylinders. This is done automatically when reverse is engaged.

For, overdrive, the oil cylinders work the other way, pulling the clutch to the left :against the spring: This is not harmful to the bearings, because, under overritive conditions, they •arenot rotating.

For operating the oil cylinders, pressure is created by a simple plunger pump and stored in a spring-loaded chamber, described as an oil-pressure accumulator. Thus pressure is constant, irrespective of speed. Control is by two ingenious valves, one of which is for reverse and the other for overdrive. The latter can be actuated mechanically through the medium of light cables or rods, or electrically by means of solenoids. The other is controlled automatically, as mentioned earlier.

A detail view shows the valves. Depression of the hollow plunger admits oil to the passage leading to the control cylinders. Raising the plunger cuts off the supply of oil and allows that in the cylinders to escape through the central bore of the plunger. Should there be a slight leakage between the ball and its seating in either position, no material failure of the valve will result.

No piping is employed, and the oil of the hydraulic system is entirely separate from the gearbox lubricant. Leakage is virtually impossible and no oil is consumed.

Whether this overdrive be employed merely as a fifth ratio, or whether the controls be arranged for its use with each gearbox ratio, is entirely optional. The latter, tctually, is more simple, but there is little difficulty in incorporating a device automatically to disengage overdrive when the lever is moved out of top-speed position

The de Normanville overdrive should be easy and cheap to manufacture and appears to possess no practical weaknesses.