The Latest in

Page 94

Page 95

If you've noticed an error in this article please click here to report it so we can fix it.

TROLLEY-BUSES

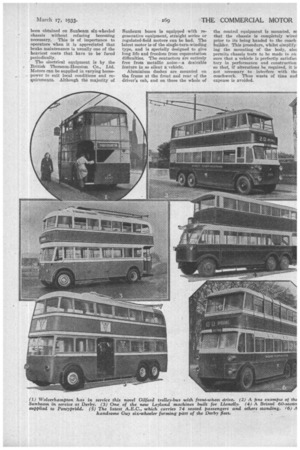

THE trolley-bus is competing on favourable terms with the ordinary bug for use in those municipalities which are either abandoning their tramways or are making extensions to existing routes, and many excellent machines of this type are being produced at British factories.

A New 74-seater.

The latest was described by us as recently as February 24. It is the A.E.C.-English Electric six-wheeler to carry the exceptional load of 74 seated Passengers and others standing. The -vehicle, which is introduced by the Associated Equipment Co., Ltd., of Southall, is 30 ft. long and is under 13 tons fully laden, whilst the chassis

• weight is 4 tons 51 cwt.

The 80 h.p. field-controlled series traction motor is towards -the rear, and transmits the drive through one short ehaft. Both motor and air compressor (for braking) are rubber-mounted. The near-side frame longitudinal is down.swept to accommodate the stepless entrance, which is approximately amidships, with the staircase immediately in front of itOther types on four . or, six wheel, are available, but the 74 • seater is in.ethe experimental stage. , The Bristol Six-wheeler.

The Bristol six-wheeled trolley-bus chassis, built by the Bristol Tramways and -CarriageCo., Ltd., -Tramways Centre, Bristol, is te carry a 60-seater body: It has an 80 h.p. Bull motor and

• B.T.H. contactor equipment. An eddy, current brake acts down to 3-4 m.p.h., when further depression operates a Westinghouse brake.

The motor is coupled to the bogie axles by a two-piece propeller shaft with centre hearing, and the bogie springs pivot on -a ,nickel-chrome steel tube. Three differentials are used. The trolley bases have adjustable roller bearings

• and are mounted on rubber.

Karrier-Clough Models.

The design of the Karrier-Clough E6 six-wheeled and E4 four-wheeled trolleybus is the outcome of the joint experiences of Karrier Motors, Ltd., of Huddersfield, and Clough Smith and Co., Ltd., of London.

The six-wheeler has a spectacles frame

• and underneath worm drive. The motor can be from 75 h.p. to 82 h.p. It is of the ventilated, commutating-pole type' of small depth, mounted amidships, -and drives through a cardan shaft with Mechanics universal joints. A shaft ' with Mechanics joints also eonneets the

bogie axles. • • Air brakes operate on all four driving wheels, whilst the hand brake expands separate shoes in the rear wheels. When required, a bogie incorporating a third differential can be supplied, also front-wheel brakes.

4:144

Front-drive Gilford-E.C.C.

In the latest Gilford-E.C.C. one-step trolley-bus, made by the Gifford Motor Co., Ltd., 465, Holloway Itoad, London, N.7, the staircase has been moved to allow full use of the platform, and clear vision has been given to the drivel-, so that he can see the trolley wires. The lowest floor height permissible is provided, permitting access by one step. From this it follows that the lowest height is obtained, thus enabling the vehicle to go under bridges 12 ins, lower than the average.

The drive being concentrated at the fore end of the vehicle gives unequalled silence in running, since vibration is not transferred through the vehicle. The back-axle springs can thus be designed for riding comfort alone, whilst this axle requires no adjustments and maintenance. All working parts are above the floor level, so that unequalled accessibility is provided for adjustments and attention.

The vehicle runs on four tyres, thus reducing tyre coats. All four wheels and brake blocks are interchangeable.

The current consumption has now been reduced to 1.6 unit per mile, and as the drivers become more accustomed to the vehicle no doubt this consumption will be further reduced.

Guy Regenerative Type.

Guy Motors, Ltd., Wolverhampton, supplies trolley-buses with either straight series motors or Guy regenerative equipment, but in view of. the economies and advantages of the latter, most are provided with it.

A single motor is fitted, for the singledeckers 60 h.p., and for the double • deckers 75 h.p. The motor is well forward, where it offers the best accessibility, and is adequately venti lated. It also permits a -lower floor height than is possible if the motor be mounted amidships. It employs a low shunt current, permitting the use of a drum-type controller, and the replacement of contacts is a matter of pence.

The low shunt current and drum controller permit 23 accelerating and decelerating positions, which give progressive acceleration and deceleration, resuiting in comfortable travel and less strain on the transmission.

One of the patented features of the Guy system is that the shunt circuit is never broken, and this, with the low shunt current results in preventing burning of the commutator, reduces wear and maintenance of contacts, practically prevents interference with wireless sets, and the vehicles will run for

long periods at slow speeds without overheating.

The system also embodies automatic control of the power pedal, by means of which the control itself is automatically locked in the regenerating position until such time as regeneration ceases.

As a result of recent improvements the motor is able to attain a higher speed and regeneration continueslower revolutions. The result is tat the six-wheeled 'doable-deckerhas now a maximum speed of 34 m.p.h. and regeneration continues to 10 m.p.h. Another feature is the small angle on the universal joints, and because of this the angular velocity is more easily balanced. A further feature is the patented braking system, which in the case of the six-wheeled trolley-bus with front-wheel brakes, provides a total area of 1,088 sq. ins, operated by 'the pedal. In the rear wheelsfern' Duplex-pattern shoes are in' each drum, and all the shoes are operated simultaneously, either by the pedal or hand-brake lever.

A Range of Sunbeams.

The Sunbeam trolley-bus chassis, built by the Sunbeam Motor Car Co., Ltd., Wolverhampton,. is available infour-wheeled and six-wheeled types. The company has aimed at producing vehicles with a similar standard of comfort, smoothness and general efficiency, as has been attained in Sunbeam cars.

With the motor in the centre. of the chassis the number of universal joints is reduced to two. This motor is housed in a sub-frame consisting of two side members, which are secured at each end to cross-members by means of pins in Silentbloc bushes. This serves the purpose of floating it, and thus preventing vibration from being .transmitted to the

frame. All leads to the motor are grouped in an accessible position, and are easily detachable, and the motor and sub-frame can be removed in 15 minutes.

Braking is effected through a 'Lackheed system., controlled by a master cylinder incorporating the Sunbeam. compensating and sealing device. This system enables perfect compensation on all six wheels to be obtained, and ensures that in the event of breakage in the pipe to any axle, that axle is immediately isolated, whilst the full braking powers of the four remaining wheels are unaffected. Brake adjustment is simple and required only at long intervals. A distabee of 80,000 miles and over has been obtained on Sunbeam six-wheeled chassis without refacing becoming necessary. This is of importance to operators when it is appreciated that brake maintenance is usually one of the heaviest costs that have to be faced periodically.

The electrical equipment is by the British Thomson-Houston Co., Ltd. Motors can be supplied in varying horsepower to suit local conditions and re5Auirements. Although the majority of

Sunbeam buses is equipped with regenerative equipment, straight series or regulated-field motors can be had. The latest motor is of the single-turn-winding type, and is specially designed to give long life and freedom from commutation difficulties. The contactors are entirely free from metallic noise—a desirable feature in so silent a vehicle.

Aluminium dashes are mounted on the frame at the front and rear of the driver's cab, and on these the whole of

the control equipment is mounted, Se that the chassis is completely wired prior to its being handed to the coachbuilder. This Procedure, whilst simplifying the mounting of the body, also permits chassis tests to be made to ensure that a vehicle is perfectly. satisfac. tory in performance and construction. so that, if alterations be required, it is not necessary to interfere with the coachwork. Thus waste of time and expense is avoided.