FACTORS ON WHICH PRODUCEF AS SURVIVAL DEPENDS

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

What Are Fortunes of

Obstacles ? Will They Prove Fatal to the Movement ? Can They be Surmounted ?

THERE are at least 11 gases of varying quality and structure made from coal or its derivative 'coke. The calorific values of these gases vary between 92 and 889 B.Th.U. per cubic ft. The lowest c.v. is that of blast

furnace gas. In the next category are three different types of producer gas with c_vs. ranging from 126 to 162 B.Th.U. per cubic ft. After them come blue water gas, 295, and carburetted water gas, 500 B.Th.U. per cubic ft. Then there are five variations of coal gas of between 475 and 889 B.Th.U. per cubic ft.

Town gas consists of a mixture of several of these gases, varying in different gas undertakings according to the declared c.v. of their products, which must be maintained within fairly narrow limits. The varying c.v. of the gases enables gas works to counteract variations in quality which it is impossible to prevent, and so to maintain the necessary heating value of the gas produced and sold'.

The calorific value of a gas is not the final indication * of its fuel value; to extract its heat, the gas must undergo combustion, and oxygen is necessary for this purpose, which oxygen is obtained from the atmosphere and mixed with the gas. This is called the explosive mixture. Different gases require for perfeet combustion different proportions of air; producer gas as used on transport vehicles requires an air/gas mixture of one to one, whereas benzene requires 35 to 1.. .

Significance of Air gas Ratio

This fact of the differing proportions of air appears to be in the nature of a balancing factor. The accompanying table of a few instances will illustrate this point.

The similarity in net 0.v. indicated extends to gases and liquids of the hydrocarbons of the paraffin, naphthalene, aromatic and olefine series. Poorest among all the gases from this point of view _are blast-furnace gas and producer gas, as the other table will show.

B_Th.U.

13.Th.U. Air/.gas per cu. ft.

per cu. ft. ratio. of mixture.

Producer gas ... 128 1.00 to 1 65.0 Blast-furnace gas ... 93 0.87 to 1 54.7 The French have a word for this producer gas, as used in road vehicles and stationary plants; they call it " gsz pauvre," which is very expressive. And this producer gas is the fuel from which we have to squeeze the power to drive our war-time road transport, according to an encouraging Government. In the meantime, we endeavour to make such improvements that the perfected gas producer may continue in the post-war years as a permanent institution.

It is necessary to remark that the calorific value of the gas is not the only property concerned in the extraction

from the gas of heat in the form of b.h.p.; compression ratio is another and very important factor having a bearing on the matter, particularly in comparing the powers extracted from gases and liquids_

The plants in gas works which produce the rich gases of our envy are not burdened with our limitations of weight and space; they can, therefore, make use of more efficient apparatus in the way of mechanically operated, continuous retorts, quite impossible for our lorries to carry about in addition to their paydoads.

So wemount on our lorries plants of which the ancestors were either the blacksmith's hearth, the forerunner of the cross-draught, or the night-watchman's brazier, the parent of all other types of producer.

Most producer plants in this country work on the crossdraught principle: the other types—up-draught, downdraught and double-draught—are much more in evidence in Continental designs.

Cross-daaught producers usually function at higher temperatures on account of the high-speed air supply. The others, all of which use low-speed air. May not require relighting the next morning. Down draughts are claimed to destroy the tar by passing it through the fire, thus converting it to fuel; doable draughts turn the gas upwards through a column of charcoal for the same purpose, but by absorption instead of dissociation.

Most types are operated under two different main conditions—with or without water injected to the fire zone. Both schools claim better results in quality of gas produced than their wet or dry competitors, as the case may be. Some of the producers are fire-brick lined and some are not. Various combinations of design features are used by different makers, indicating the widely differing views held on the underlying principles, and the incompleteness of co-ordinated research.

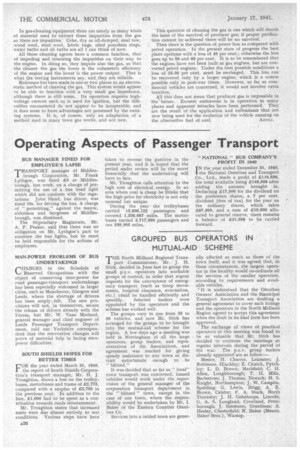

Dynamometer and gas-analysis tests provide some surprises, and the necessity of revising theories previously put forward. The disturbing revelations of cold truths tend to bring down criticism of the informing instrument, and on its suitability for the purpose. The road test, it is contended, shows what a producer can do. Yes, but the dynamometer and the calorimeter show how it does it, and often, why it doesn't do it. For instance, the accompanying chart shows how the c.v. of the gas falls off from almost the beginning to the end of a 100-mile journey.

This chart also shows that the hydrogen content of the gas falls sharply, and continues to fall, that the methane gradually disappears, and that, despite the rise of the carbon-monoxide content, it is the fall of the hydrogen that causes the decline in the calorific value.

Incidentally, the smallness of the methane content in producer gas—when there is any at all—is responsible for the drop in calorific value from the nineties to the sixties, as shown in the foregoing tables, Hydrogen is evolved in large quantities up to 700 degrees C. Carbon monoxide (CO) is not produced until 900 degrees C. is reached. As the fuel is stored in the same container as the fire-zone at from 1,000 degrees C. to (claimed by some) 2,000 degrees C., the hydrogen is driven off, not only from the fuel undergoing combustion, but also from the fuel above, always in advance of its time, so that increasingly " second-hand" fuel is fed to the fire zone, with the result's as shown on the chart, and, incidentally, experienced by the FUEL driver whose job it is to get the load to its destination. Water injection is resorted to by some manufacturers to increase the hydrogen content of the gas. Bench tests, however, show that any increase of hydrogen is dissipated by other inefficiencies in the plant not yet understood and no increase in engine power results, Because water vapour is the cause of acids in the gas that would not he there without it, the addition of more water does not improve this position. There are, of course, some designers who use water in the fire only for the purpose of breaking up clinker, and not in an endeavour to increase the hydrogen content of the gas.

Prospects of increased power rest on the possibility of using a high-compression ratio of this gaseous fuel. There is a difficulty, however, on this point, due to producer gas not being a simple gas. Its gaseous constituents have different properties, and, in relation to compression ratio. the relevant property of flame speed of the composite gas is one-seventh that of its hydrogen content.

On hydrogen an effective compression ratio of 14 to 1 has been used successfully; but on account of the large difference in the flame speeds of the component gases this ratio cannot be attained.

Dirty as Compared with Town Gas Operators are afraid of damaging or ruining their engines, on account of the filth, as they call it, in the gas. Anyone used to the comparative cleanliness of town gas, where such thorough efforts and huge plants combine to ensure this cleanliness, is really a bit hazy as to what undesirable constituents there are in our producer gas. You would be surprised; there's nothing like writing things down; they. permit of much closer examination than if they exist only in thought.

Here, then, are the impurities that do (don't say they can't; they do) get into our engines:—Cdal dust, ash, tar, moisture, sulphur, chlorine, acids, ammonia.

That's a pretty formidable list of undesirables to put in the gas, or, being in, to take out.

Coal dust and ash are drawn into the gas system by the engine suction, as might be expected with engine speeds up to 3,000 r.p.m. Tar is formed between 500 and 700 degrees C. and is not destroyed until a temperature of 1,300-1,400 degrees C. is reached, so that there are conditions existing at times which permit of its being drawn into the gas stream.

There is a moisture content in the fuel itself, and moisture is, furthermore, a product of combustion, Take off the lids anywhere in the system when the plant is cold, and condensed moisture will be found.

Sulphur is deposited in the pipes, so that throttle valves become fouled by it. There are conditions of running in which water combines with chlorine and sulphur and forms acids which attack cylinder walls and deteriorate the lubricating oil in the sump. In the case where more moisture is added to the system by water injection to the fire zone, this condition is obviously not improved. In gas-cleaning equipment there are nearly as many kinds of material used to extract these impurities from the gas as there are impurities. Coke, dry or oil-damped, sisal tow, wood wool, steel wool, fabric bags, oiled porcelain rings, water baths and oil baths are all 1 can think of now.

All these cleaning agents have a common function, that of impeding and retaining the impurities on their way to the engine. In doing so, they impede also the gas, so that the cleaner the gas the lower is the volumetric efficiency of the engine and the lower is the power output. That is what the testing instruments say, and they are reliable. , Reference has been made in one or two places to an electrostatic method of cleaning the gas. This system would appear to he able to function with a very small gas impedance, although there is still some. Its operation requires highvoltage current such as is used for ignition, but the difficulties encountered do not appear to be insuperable, and it does seem to have advantages not possessed by the existing systems. It is, of course, only an _adaptation of a method Used in many town gas works, and not new. This question of cleaning the gas is one which will decide the issue of the survival of producer gas; if proper purification cannot be achieved there will be no survival.

Then there is the question of power loss as compared with petrol operation. In the present state of progress the best plant operates with a loss of 40 per cent.; otherwise the loss goes up to 50 and 60 per cent. It is to be remembered that the engines have not been built as gas engines, but are converted petrol engines. Under the best possible conditions a loss of 25-30 per cent, must be envisaged. This loss can be recovered only by a larger engine, which is a course possible only in post-war times. However, *so far as commercial vehicles are concerned, it would not involve extra taxation.

All this does not mean that producer gas is impossible in the future. Earnest endeavour is in operation in many places and apparent miracles have been performed. They are the result of the application and enthusiasm that are now being used for the evolution -of the vehicle running on

the alternative fuel of coal. AZIYU.