Reach for the

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

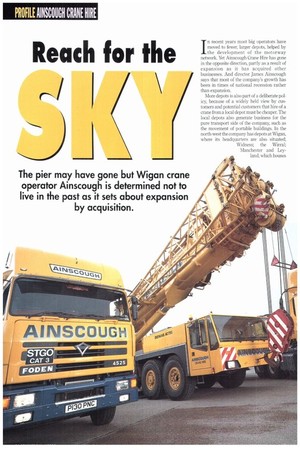

The pier may have gone but Wigan crane operator Ainscough is determined not to live in the past as it sets about expansion by acquisition.

In recent years most big operators have moved to fewer, larger depots, helped by the development of the motorway network. Yet Ainscough Crane Hire has gone in the opposite direction, partly as a result of expansion as it has acquired other businesses, And director James Ainscough says that most of the company's growth has been in times of national recession rather than expansion.

More depots is also part of a deliberate policy, because of a widely held view by customers and potential customers that hire of a crane from a local depot must be cheaper. The local depots also generate business for the pure transport side of the company, such as the movement of portable buildings. In the north-west the company has depots at Wigan, where its headquarters are also situated; Widness; the Wirral; Manchester and Leyland, which houses its national heavy cranes division. All told there are 15 depots, Grangemouth is the most northerly and Maidstone the furthest south, Three brothers, Martin, Brendan and James, run the business.

The glamorous side attracts the most attention: a new 400-tonne Demag mobile crane costing f1.75m was delivered last month. But most of the work is more humdrum. Ainscough offers a "one-stop shopping" concept to clear a site or move a complete factory. One side of this, warehousing, has been embarassingly succesful. This is not warehousing for packets of cornflakes but for huge items of plant.

Heavy equipment

Often heavy equipment will be moved off one site, but its new location will not be ready for some weeks and Ainscough will be asked to store it temporarily. Doing just this will require heavy tackle to load and off-load, and a large building with ample height for storage. Recession has often meant bankruptcies, with factory equipment being sold off and moved.

Another trend, which started in recession, but shows no sign of slowing, is for manufacwring companies to consolidate or reorganise and shift equipment into fewer buildings. Regular work comes from a variety of wellknown names, such as British Aerospace, and involves moving out old equipment and installing new, often over a weekend, usually beginning Friday lunchtime and finishing Sunday afternoon, Moving heavy presses invariably involves Ainscough's 160-tonne or its new 460-tonne jacking systems. For the on-site work there are crews of three, but a big job would involve more than one crew. Each crew has its own tackle van and a typical recent day saw one crew working in North Wales, another in Bristol, a third in Ellesmere Port and a fourth in Scotland. Occasionally a single job may take as long as 18 weeks.

There is also work at the other end of the weight scale for specialist aluminium roof producer Hooghoven. The company makes extrusions for the roof structures of large industrial buildings. Some of these sections will be curved, and need timber supports of similar shape to prevent distortion in transit. The longest moved so far is 55m long, and hauled by a Mercedes-Benz 2644 6x4 tractor with one bogie placed toward the rear end of the load and the second nearer the front.

The Mercedes-Benz has a very low speed capability, essential for this work. Ainscough claims it is the longest supported load ever carried in the UK. From front of tractor to back of load it measured 65m.

Ballast tractors

Recent additions to the Ainscough fleet are four new Foden 4000 Series tractors to run at 100 tonnes gross, though designed for 150 tonnes for passible later requirements. These are ballast tractors, with a relatively long wheelbase of 4.6m, double-flitched chassis frame, rubber Hendrickson suspension, Sisu tandem-drive axles, Cummins 14-litre engines and 18-speed Fuller gearboxes.

The big, high XL double-sleeper cab is fitted, and there is a non-oscillating fixed Jost fifth wheel.

The Fodens pull new five-axle Nooteboom trailers which carry ballast and weights for the large mobile cranes. They are flat topped, but replace older, five-axle semi low-loading trailers. The Nootebooms are of the makers' latest design, with hydraulic suspension and power steering to each axle, which have a big range of travel and truck-sized wheels and tyres to reduce tyre wear.

The previous trailers are now used for the other work in the fleet. With their small wheels on rough ground one (or more) axles could lose contact with the surface, leading to axle bending and premature tyre failure.

As well as the new 400-tonne Demag mobile crane, for any work well away from base such cranes are usually partially dismantled and moved by lorry, with the main jib section carried on a low-loader. A typical job would involve eight bailer loads, carrying ballast and weights, jib sections, hooks and blocks, luffing booms, a 34-tonne all-terrain crane (as well as the large Dune), a fork-truck, and timber and packings. "Big Jack", the £500,000, 460-tonne jacking system alone needs four or five trailers, depending on the job. The four legs will go on one trailer and then there are two beams, two power packs, rails (for the jacks to run on) and stillages.

Much of the work and equipment is less dramatic than this. One recent purchase is a fleet of 20 Tadano Faun cranes worth £4.5m. Seven are 50-tonne all-terrain machines, but there are six 35-tonne and seven 25-tonne truck-mounted cranes.

Printing presses, boats and barges, railway signal gantries, an aircraft fuselage, statues, bridges and even an inflatable Father Christmas are all among the items lifted and moved by Ainscough in the past 12 months. It even moved a dock crane with three of its own mobiles.

It is all a far cry from the six cranes—an 18tonner was the largest—and an Atkinson Borderer tractor and 40ft trailer with which the company began just 25 years ago.

E by John Aldridge