Moving on up

Page 30

Page 31

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

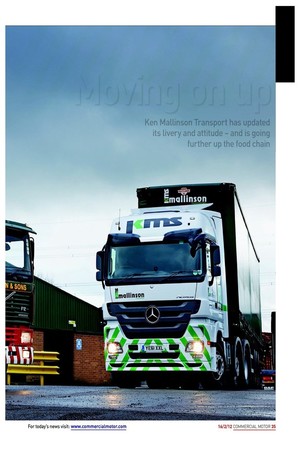

Ken MaLLinson Transport has updated its Livery and attitude – and is going further up the food chain

The switch from a traditional looking sign-written truck to a body-in-white vehicle adorned with the company name in new modern colours is hardly a ground-breaking switch. But heritage is something we in the haulage industry like to think we do rather well. Even well-known names such as Stobart, Wincanton and Bibby consider themselves businesses with tradition – a family backbone that once, in the early years, helped drive success.

Liveries are the ingerprint of the haulier – Stobart knows this, which is why its truck washing routine borders on the obsessive-compulsive – and for an independent family business, hand-written liveries convey an image of warmth and approachability.

It stands to reason, therefore, that changing your ‘ingerprint’ as a minnow in the competitive stream of operators could be detrimental to your identity. However, this has not been the case at Ken Mallinson & Sons Transport where business has been booming since it irst switched its livery from traditional green, red and yellow to a fresh white and green livery in mid-2010.

No longer a small ish in its local area, Ken Mallinson Transport is making moves – quite literally – up the food chain, and the signiicance of its livery change is twofold. Switching to stickering trucks straight from the factory has helped cut costs signiicantly and at the same time reduced downtime.

More importantly, the change symbolises a transformation for the company from a family haulier operating just a few trucks on local routes to a national operator transporting goods for one of the UK’s largest supermarkets.

Latest acquisitions

Ian Egan, business development manager at Ken Mallinson, says: “We’d have spent £4,500 [with the paint and old livery], and on 85 vehicles the cost stacks up. It’s an obvious cost saving as we add more vehicles to the leet, not to mention the two weeks saved in the painting shop. Now the vehicles arrive on the Monday, get stickered up on the Tuesday and are working by Wednesday.” The vehicles have been coming in at a fairly constant rate since Egan took up the role of business development manager more than three years ago. In fact, the company has had to upgrade its O-licence to cope with the expansion.

Among the most recent acquisitions are 10 new Mercedes-Benz Actros tractors, which joined the leet in late 2011, and have just been joined by two 26-tonne Daf CF85 6x2 rigids. The vehicles are Euro-5 compliant, and have been chosen with their fuel economy in mind, but it is the 25.46 Actros units with Megaspace cabs and automatic transmissions that have won favour through the Ken Mallinson leet, both with drivers and the company.

Egan says: “There’s no doubt the Mercedes are the least problematic trucks we run. They’re all bought on a hire purchase deal, and were chosen based on driver value.

“We put 20 on the road the year before, and added 10 more last year because they perform. As a leet they achieve an average of 9.22mpg, that’s above the rest of the leet which includes Daf, Renault and Iveco trucks. The Mercedes get a good fuel return, which is why we have them, but if it’s pleasing on the eye and goes down well with the drivers it is also advantageous for a company that is keen to go forward.” The new additions have seen Ken Mallinson’s vehicle parc expand to 85 units, a signiicant move from the family orientated roots of the company.

“We run 180 trailers, and have deinitely transformed ourselves from a family haulier into a mainstream haulier. Our initial plan was to be up to 100 tractor units by 2014/2015, so we’re on target, if not ahead of schedule,” says Egan.

Ever the optimist, he believes the key is to keep going even when times are tough, and says that running a haulage business is a way of life that you either understand or don’t.

Having sold out of his own road transport company in 2004, Egan would clearly put himself in the camp of those who ‘get’ the industry, and sees no reason to be pessimistic despite the recent tough times.

“Even if it [business] does get worse you’ve still got to look forward. It’s deinitely been tough growing during a recession, but the secret has been to not stand still. It has not been an easy time for the company, and proits aren’t where they should be, but you need the foresight to see that when it [a large contract] does come you are able to pick it up, and we are perfectly placed to do that.” Flexibility has been a key to the company’s success, picking up work where others have fallen short, and has helped Ken Mallinson Transport achieve some noteworthy recognition.

Named as its secondary carrier of the year by Asda in 2011, a large proportion of the South Yorkshire-based haulier’s business consists of work for the supermarket, as well as additional general haulage.

However, Egan says the company is capable of picking and choosing the work that is suitable for it.

He adds: “Working for the supermarkets is good bread and butter work, seven days a week. But we also do a lot of utility work and specialist work, and will take on speciic jobs if they’re worthwhile. We’re not in a position where we have to go to a board [for approval] and then months later something happens. We’re a bit more dynamic than that, so we can pick the work we want because we’re in a good [inancial] position.”

Worth looking at

Growth and diversiication are clearly on the cards for Ken Mallinson Transport, and for Egan who says that, if the opportunity arose, ADRs, tankers and setting up a base elsewhere in the UK to accommodate a contract would be worth having a look at. Nothing seems to be too daunting. Not even rising operating costs and the thought of longer semi-trailers.

“Fuel is a key cost,” says Egan. “I don’t think it will ever go down, but it will stabilise. It’s not a good time for the industry. We’ve got nine double-deck trailers working store delivery routes from Doncaster. We it a big aerofoil and use close coupling to improve eficiency and make the most of our fuel.

“We’ve standardised trailers to 4.5m so new trucks have big aerokits, but the problem with double-deck trailers is that often you can’t backload them because of health and safety. Aerodynamic trailers also won’t work for us because we frequently have 52 pallet loads, with a lot of plastic products and glass bottles. We work with what we can.” A livery change could be just the start for the new look Ken Mallinson, because Egan is keen not to rule out anything that could help the company progress.

“Longer semi-trailers look like a good idea, but can only have 44 tonnes, so you still get the same scenario if you run a heavy product,” he says. My fear is that customers will expect you to take more pallets for the

same price. I’m not sure about them, but if they became common we’d have to go with it. For us drawbars are better than longer semi-trailers. We’ve only got one, for a speciic contract, but it works. For many sites, longer trailers are no good. Most of the places we go in and out of are just about artic friendly, so with a bigger trailer it would be really dificult. But I’m not ruling it, or anything, out yet.” ■

AUTHORISED TESTING FACILITY

With around 60% of its fleet already paid for, Egan says Ken Mallinson Transport is well placed to take advantage of demand in growth sectors such as recycling. It has invested in an Authorised Testing Facility (ATF) to help its own fleet management and capitalise on a local demand for testing and maintenance services.

“We’re in a triangle, between Leeds, Doncaster and Sheffield, so the amount of time taking trucks for testing adds up. It’s a 30-minute trip each way to each of the testing sites, plus the fuel and the driver costs, so it is a four-hour round trip, for truck and trailer, not to mention the costs and the carbon footprint. We have a three-lane maintenance facility on site for our own trucks, so it was a pretty obvious decision to apply for ATF status.

“Testing is only one day a week, but the garage has been 24 hours for about nine months, which means there is minimum downtime for our fleet. Primarily, the reason for the ATF was to keep our fleet 100% compliant, but we’ve now got some regular work, and have interest from local companies and councils. If we can build on the number of people coming in it is going to be good for the whole facility.”