GLASS

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

By with Ashley Taylor A.I.R.T.E.

7 ROAD ALONG the roads of Britain one frequently encounters the smart green vehicles of Pilkington Brothers, Ltd., St. Helens, usually carrying heavy loads of glass. With a product which, in the transport industry, falls into the fragile class, the organization has long paid special attention to the problems of distribution. In fact, although the original choice of the town as a site for the business was substantially due to the presence locally of raw materials, the proximity of a coastal port and a canal were further important factors.

The name of Pilkington tirst came to be associated with the glass-making industry in 1826. William and Richard, the two original, founders, were sons of a Dr. William. Pilkington, who came to St. Helens from 14orwich. Through them it Came about that, during the reign of King George IV, crown glass was first manufactured in the town.

Vast Developments

The original factory stood on II acres of ground and ultimately employed something like 300 expert workers. During the 124 years that the business has existed, a period covering the reigns of six sovereigns and four generations of directors, the technical knowledge and skill acquired have brought about vast developments. After the establishment of the crown glass industry, came the introduction of the cylinder-blown and cylinder-drawn processes which finally gave place to the modern, flat-drawn, mass-production method.

A new plate-glass works was erected in 1876 and manufacturing improvements, after about 25 years, brought about the perfection of the first mechanically operated lehr for the annealing of plate-glass; later, in 1921, the Bicheroux method of casting was introduced.

Years of Research Finally came the twin grinding and polishing plant in which the ribbon of glass, after flowing from the furnace and being annealed, passes under grinding and polishing heads which operate on both surfaces of the glass simultaneously. Years of research, at a cost of over 11,000,000, went into this plant, which is more than 1,000 ft. long and was the first of its kind in -the world.

This gradual but continual process of development, particularly during the past 30 years, has brought about almost wholly mechanized methods of manufacture, accompanied by increases in the area of the works to over 600 acres and the number of employees to well over 10,000 at the St. Helens factories alone.

From quite ordinary beginnings the interests of the business have grown until they are world-wide and the sales organization necessitates not only a network of depots covering this country, but agencies and branches in many lands overseas and connections through sub-agents in almost every corner of the globe.

There are sheet-glass manufacturing plants at Pontypool, South Wales, and at Queenborough in Kent, whilst at Doncaster there are plate-glass and Vitrolite works. New plants for the manufacture of flat-drawn sheetglass are being erected in Canada and South Africa, and there are processing plants in various other countries overseas.

All this spells a succession of problems for the transport department which, to cite only one instance, was recently called upon to prepare eight Guy Otter oil-engined lorries for operation in Assam, running to a riverhead point in connection with the transport of special refractories. These vehicles were entirely constructed of light alloys to resist the attacks of ants and similar, insects, rubber being the only other material in the bodies. These machines have four-wheel drive with a special rear axle and gearbox ratios so as to deal adequately with the excessive gradients which are encountered durthe journey down the Himalayas and over the paddy field bullock tracks.

In the early days of the concern, materials were carried first by barge on the canals, later by horse-drawn cart and then by a fleet of steam wagons..

Factories and Depots Mr. G. L. Bingham, the present transport manager of the company. now controls a . fleet which has garages at the various factories in this country and, in addition, at depots in London, Birmingham. Nottingham, Leeds, Bristol, Glasgow, Newcastle upon Tyne and

Bradford. •

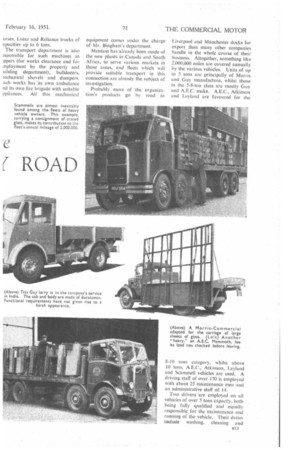

Over 125 glass-carrying delivery vehicles arc located at the St. Helens headquarters and, in addition, there are nearly 40works transport vehicles employed on internal and inter-plant movement; the latter are principally Scammell mechanical

8-10 tons category, whilst above 10 tons, A.E.C., Atkinson, Leyland and Scammell vehicles are used. A driving staff of over 150 is employed with about 25 maintenance men and an administrative staff of 14.

Two drivers are employed on all vehicles of over 5 tons capacity, both being fully qualified and equally responsible for the maintenance and running of the vehicle. Their duties include washing, cleaning arid routine attention, a nightly washdown being the rule, except when away from base. At this stage it may he of interest to observe that special attention is given to the question of industrial relations, and all members of the staff can have direct access to the transport manager Mr Bingham meets a committee, consisting of a representative from every section of the department, from time to time for a frank discussion without regard to position, during which th:. men are invited to express views about working conditions and the means by which efficiency can be increased This system has been found to be notably advantageous, for it prevents pin-pricks festering, as they may do if left to wait for the occasional union meetings These conferences are quite informal, there being no agenda or recorded minutes. and the works' representatives are chosen by the men themselves.

Incentive Scheme Records show that it is not uncommon for men to retire with over 40 years' service, and in some cases three generations of a family are employed. For the drivers, an incentive scheme which takes the form of trip rates is in use. Working is controlled by allowances., which are paid on the basis of 16 m.p.h. average with a vehicle limited to 20 m.p.h.. or 20 m.p.h. if the vehicle is of the 30 m.p.h. class In addition, an adequate subsistence allowance is paid to drivers who are away from base all night or out from the depot all day.

Dating from the horse-drawn era is the practice of giving a shilling to a driver going out of St. Helens. This allowance was originally granted so that the driver could water his horse at an inn, this facility not unnaturally being available only when the man went into the place for personal refreshment, a thing which without an allowance he might well not be disposed to do.

At the time of my visit to St. Helens, considerable extensions were being made to the transport department premises and on completion of these changes the former office accommodation is to be refitted as a canteen and rest room for the transport staff. For many years particular attention has been paid to welfare and to a rehabilitation system with the latest medical; dental and optical facilities.

When the extensions are completed the present amount of garage s14

accommodation and fuelling capacity will he doubled and the maintenanceshop will be enlarged Opportunity has also been taken to incorriorate .a bigger office block, 'and the administrative section will overlook the garage. Body repairs are already carried out at the works, but in the future it is hoped to provide a cornplete bodybuilding and paint shop.

Holiday Overhauls When a defect develops during the day, a report is made by the driver concerned on a special form, which is handed to the fleet engineer. Apart from this, routine fortnightly inspections are given by the maintenance staff during the week-ends. In addition to the regular cleaning, each machine is polished at weekly intervals. What is in every sense a major overhaul takes place each year when the driver's annual holiday comes round

The maintenance section is equipped with extensive pits, and high-pressure greasing and washing

equipment. Lubricating oil is reclaimed by the Filtrate process after use in the sumps of delivery vehicles, and is then transferred to store for use in internal works transport. To prevent skin irritation, barrier creams are imariably used by maintenance personnel: Detailed records of the costs of the various jobs carried out by the vehicles are maintained by the transport department account, and these are charged against the departments concerned. All costs are summarized and then broken down into expenses per lorry-mile, expenses per ton and expenses per ton-mile. Payments taken into iccouflt,,ifl aSsesSiggftliese

costs include petrol and oil fuel, lubricating oil, drivers' wages, drivers' subsistence allowances and expenses, repair workers' wages. repair materials, reserve against future repairs, tyre costs and materials, together with reserve against future tyre costs, insurance, depreciation, 'fixed general charges, management and office staff expenses,' together with motor depot and sundry expenses Thus, an accurate picture of the cost of delivering the company's products by its own transport is developed. It is safe to say that, when comparing expenses with those of public carriers, a perfectly fair picture is given and none of those invisible advantages appears which sometimes occur through failure to take into account certain benefits derived from parent organizations.

• Breakages Minimized Glass is regarded as being an extremely vulnerable load for most forms of transport. The Pilkington transport department, however, with its extensive experience, holds no such opinion. By using felt-lined baulks and a clamping arrangement, breakages are minimized. Between 60 and 90 tons of glass are delivered each week to Northern Ireland alone, the consignments being looseloaded at the works and not touched until they arrive at the customer's premises after a road journey and a passage on the Preston-Larne vehicle ferry. Even in these circumstances damage has proved negligible, and crossings of the Irish Sea by every passage for months on end have not produced a single breakage.