Set the standard design the system

Page 71

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

BY JOHN PROCTOR HOW often have you seen a GPO vehicle

being towed in to workshops or immobilized at the roadside? I cover 1.200 miles each week and on only one occasion during the last six months have I come across such an unusual sight. The reason, I suggest, is that the GPO motor transport section has the most comprehensive maintenance system I have ever examined.

It is a system born of experience and flexible enough to be altered to meet new circumstances. It is not tailormade for one fleet— it can be expanded or scaled down to meet the needs of most operators.

GPO motor transport headquarters are at Gresham Street, London EC2, and it was here I was introduced to the system by Mr. M. C. Humphrey, one of two MT0(1)s who serve on the staff of Mr. F. A. Hough, the chief MTO. The other officer is Mr. P. E. Brownlow. Headquarters staff are responsible for main

tenance and purchasing policy. They set standards and then advise regions how to achieve them.

The magnitude of this task is better understood when I tell you that there are 10 regions and 480 workshops. Each workshop has an average of 120 vehicles, although some may have very many more. We are therefore looking at a system covering 54,000 vans scattered in units of varying sizes throughout Great Britain. The vehicles in the fleet are divided into two groups—one serving postal needs and painted red, the second group used by the engineering branch and painted green.

The first point to be examined by any organization considering a servicing and repairs programme is surely the number of employees required. As I have said, this system was born of experience. Records from the past were examined and analysed, and questions were asked. How many men were required to service a +-ton van? Or, how many +-ton vans could be serviced by one man? The information was carefully sifted, and conditions at all depots were considered. The end product told the GPO men what staff they required for any depot no matter what permutation of vehicles existed at that depot.

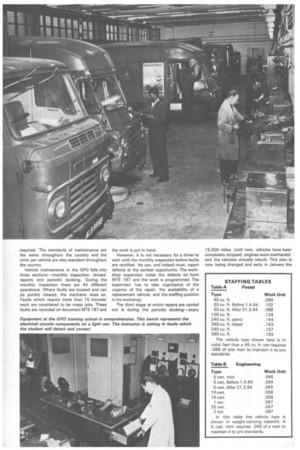

Postal vans are measured in cubic capacity and engineering vans are measured in carrying capacity in cwts. The current staffing tables are reproduced, showing vehicle types and work units. Work units indicate the amount of manpower required to maintain a vehicle of the size indicated. It will be seen that where there are 10 45 Cu. ft. vans, one mechanic is required. The standards of maintenance are the same throughout the country and the units per vehicle are also standard throughout the country.

Vehicle maintenance in the GPO falls into three sections—monthly inspection, drivers' reports and periodic docking. During the monthly inspection there are 44 different operations. Where faults are located and can be quickly cleared, the mechanic does so, Faults which require more than 15 minutes' work are considered to be major jobs. These faults are recorded an document MTE 187 and the work is put in hand.

However, it is not necessary for a driver to wait until the monthly inspection before faults are rectified. He can, and indeed must, report defects at the earliest opportunity. The workshop supervisor notes the defects on form MTE 187 and the work is programmed. The supervisor has to take cognizance of the urgency of the repair, the availability of a replacement vehicle, and the staffing position in his workshop.

The third stage at which repairs are carried out is during the periodic docking—every 15,000 miles. Until now, vehicles have been completely stripped, engines were overhauled, and the vehicles virtually rebuilt. This plan is now being changed and early in January the change will be complete. While the 15,000mile docking will be as comprehensive as the previous method, it will take less time. At the central workshop at Yeading, Middlesex, under the overall control of Mr. Albert Hicks, 100 vehicles a week will pass through the shop on a flow-line system. Overhauls are being superseded by replacement of units. From first inspection to last inspection, the vehicles will be in the workshop at most for five days. During the docking any repairs required in addition to the replacement units will be carried out. This system is being introduced for London and Home Counties vehicles and after a testing period it may be extended to other regions.

During the life of a vehicle it will be docked three times. Policy is to replace at about 50,000 miles. This, for postal vehicles means about four years' service and for engineers' vehicles about six years'. Until now vehicles have been standardized, but the policy now is to purchase in the most favourable market. With a fleet of this size obviously vehicles and spares are purchased at very favourable discounts, and cost comparisons would indicate little to most other operators.

I must return to the mainspring of the maintenance system, the MTE 187. This is a most comprehensive job card and leaves nothing to chance. It removes doubt from the mind of the mechanic, it tells "where, when and how long", and it provides a case history for each vehicle which eventually is entere&.in the vehicle history sheet. MTE 187 collates the information which is eventually passed to the regional motor transport officers, to show them the fault-mileage ratio. Comparisons can be drawn between regions, between workshops and even between vehicles. This document is also used for cost control and management statistics. Frequently criticism is levelled at Government departments concerning the mass of paperwork involved in a job. This does not apply to the GPO; MTE 187 is one of a very few, but it has been so designed that it does the job of very many.

The chain of command at GPO travels from headquarters through regions down to workshops. At district workshops such as Camden Town, the vehicles are serviced and repaired to the set workshop pattern. The workshop supervisor is given sufficient authority to ensure that there is a minimum of "down

time". Contrary to public opinion, the GPO does not have unlimited resources nor large reserve pools. The vehicle reserve depends on the class of work on which the vehicle is engaged. The engineers' department has one reserve for every 10 vehicles, the postal is one to six.

There is, in transport, one factor common to all operators large and small—personnel. Purchasing top-quality vehicles and laying down maintenance standards would not take the GPO very far if it did not have the staff to carry out the work. It has the staff and a well-trained staff it is.

The GPO has one advantage over most operators: it is dealing with only one union— the Post Office Engineering Union. Men are designated garage assistants, Meth IA}, or senior mechanic. The advantages are that lines of demarcation do not exist. A mechanic can beat panels, spray panels, rewire or carry out repairs to any of the mechanical components on the vehicle. The concept of a fiveyear trade apprenticeship does not exist. A Mech.(A) is the widest single grade of employee and it is here that the GPO scores. Provided a man has served an automotive apprenticeship in any section of the trade, he is recognized as a Mech.(A).

Recognition is one thing, skill is something quite different. How does an engineer acquire the skill of an electrician or a panel beater? Simply by training. At Yeading the GPO has a training school. Here students are trained in the arts of auto electrics, diesel engine repairs, arc and gas welding, hand tool construction and use, mechanical repairs and body repairs. These courses are voluntary and about 1,000 students attend annually. In addition, apprentices are required during the course of their three-year apprenticeship to attend two residential courses of three weeks duration annually. They must also complete the City and Guild syllabus. The aim of the GPO is to train apprentices and retain them in the service on completion of apprenticeship.

The plan for maintenance of GPO light vans is to inspect and repair regularly, using the minimum documentation and skilled, welltrained labour. It cannot be argued that only an organization as large as the GPO can employ this method. Assessment of labour requirement is a managerial function in any industry and can be arrived at in the same way as did the GPO. One need only referto records and then relate the answers to the standard one sets. Assuming that you are operating a small fleet and do not yet have your own labour force, the records to which you must refer are last year's invoices.

Nothing could be more simple than GPO documentation. The MTE 187 is all you re

quire to get the system off the ground. It is easy and indeed a temptation—to add to systems: the MTE 187 makes this unnecessary. Other documentation used by the GPO is of a domestic nature and is not essential in any other type of business.

The one point beyond which others are, for the moment, unable to penetrate is the line of demarcation. I understand the GPO has been enjoying this union co-operation for about five years. The service is certainly receiving the benefit and the men are acquiring more skills than their commercial counterparts. It may be that under the auspices of the Industrial Training Board commercial undertakings will enjoy this same flexibility in future. There is one factor which is all-important and which applies to all operators large and small: the system was made to meet a standard. The GPO motor transport department asked, "What standard do we set ourselves?" Having answered that question they then agreed the system. The standard is high, the system is excellent and it works. If you doubt this I ask you again: how many times have you seen a GPO vehicle being towed-in or sitting immobilized at the roadside?