An Improvement in Radiators.

Page 3

If you've noticed an error in this article please click here to report it so we can fix it.

A Method of Fitting Gilled Tubes without employing Solder or other Rigid Means of Attachment.

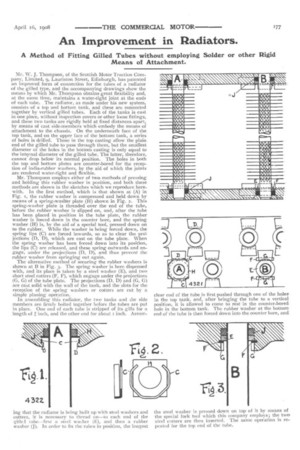

Mr. W. J. Thompson, of the Scottish Motor Traction Company, Limited, 9, Lauriston Street, Edinburgh, has patented an unproved form of connection for the tubes of a radiator of the gilled type, and the accompanying drawings show the means by which Mr. Thompson obtains great flexibility and, at the same time, maintains a water-tight joint at the ends of each tube. The radiator, as made under his new system, consists of a top and bottom tank, and these are connected together by vertical gilled tubes. Each of the tanks is cast in one piece, without inspection covers or other loose fittings, and these two tanks are rigidly held at fixed distances apart, by means of cast side-members which embody the means of attachment to the chassis. On the underneath face of the top tank, and on the upper face of the bottom tank, a series of holes is drilled. Those in the top casting allow the plain end of the gilled tube to pass through them, but the smallest diameter of the holes in the bottom casting is only equal to the internal diameter of the gilled tube. The latter; therefore, cannot drop below its normal position. The holes in both the top and bottom plates are counter-bored for the reception of india-rubber washers, by the aid of which the joints are rendered water-tight and flexible.

Mr. Thompson employs either of two methods of pressing and holding this rubber washer in position, and both these methods are shown in the sketches which we reproduce herewith. In the first method, which is that shown at (A) in

r, the tubber washer is compressed and held down by means of a spring-washer plate (H) shown in Fig. 2. This spring-washer plate is threaded over the end of the tube, before the rubber washer is slipped on, and, after the tube has been placed in position in the tube plate, the rubber washer is forced down in the counter bore, and the spring washer (H) is, by the aid of a special tool, pressed down on to the rubber. While the washer is being forced down, the spring lips (C) are forced inwards, so as to clear the pro= jections (D, D), which are cast on the tube plate. When the spring washer has been forced down into its position, the lips (C) are released, and these spring outwards and engage, under the projections (D, D), and thus prevent the rubber washer from springing out again.

The alternative method of securing the rubber washers is shown at B in Fig. 3. The spring washer is here dispensed with, and its place is taken by a steel washer (E), and two short steel cotters (F, F), which engage under the projections (G, G) of the tube plate. The projections (D, D) and (G, G) are cast solid with the wall of the tank, and the slots for the reception of the spring washers or cotters are cut by a simple planing operation.

In assembling this radiator, the two tanks and the side members are firmly bolted together before the tubes are put in place. One end of each tube is stripped of its gills for a length of inch, and the other end for about I inch. Assum

ing that the radiator is being built up with steel washers and cotters, it is necessary to thread on—to each end of the gilled rube—first a steel wat,her (E), and then a rubber washer (J). In order to fix the tubes in position, the longest clear end of the tube is first pushed through one of the holes. in the Lop tank, and, after bringing the tube to a vertical position, it is allowed to come to rest in the counter-bored hole in the bottom tank. The rubber washer at the bottom. end of the tube is then forced down into the counter bore, and the steel washer is pressed down on top of it by means of the special fork tool which this company employs; the two. steel cotters are then inserted. The same operation is repeated for the top end of the tube.